Replacement Parts for Milwaukee Portable Band Saws

Replace bearings, cords, screws, and other parts on Milwaukee portable band saws.

| Component | Manufacturer Model No. | Each | |

For No. 6225/6226 | |||

|---|---|---|---|

| 10-24 × 1/2" Pan Head Torx Screw | 06-82-8864 | 00000000 | 00000 |

| Blade Pulley | 28-95-0120 | 00000000 | 00000 |

| Blade Pulley Axle | 42-12-0070 | 00000000 | 00000 |

| Blade Pulley Sleeve Bearing | 42-40-0580 | 00000000 | 0000 |

| Bumper | 42-38-0032 | 00000000 | 0000 |

| Cord Set | 22-64-3200 | 00000000 | 00000 |

For No. 6225/6226, 6232-20/6232-21, 6238-20/6238-21 | |||

| 10-24 × 7/8" Pan Head Torx Screw | 06-82-5574 | 00000000 | 0000 |

| Blade Pulley Tire | 45-69-0010 | 00000000 | 00000 |

| Pulley Hub Washer | 45-88-7165 | 00000000 | 0000 |

| Snap Ring | 34-60-1400 | 00000000 | 0000 |

For No. 6225/6226, 6238-20/6238-21 | |||

| Switch | 23-66-2726 | 00000000 | 00000 |

For No. 6232-20/6232-21 | |||

| Cord Set | 22-64-0440 | 00000000 | 00000 |

| Gearcase Cover Kit | 14-30-0010 | 00000000 | 00000 |

| Switch | 23-66-0645 | 00000000 | 00000 |

For No. 6232-20/6232-21, 6238-20/6238-21 | |||

| 10-24 × 1/2" Pan Head Torx Screw | 06-82-5314 | 00000000 | 0000 |

| Blade Guard | 43-54-0085 | 00000000 | 0000 |

| Blade Pulley | 28-95-0050 | 00000000 | 00000 |

| Blade Pulley Axle | 42-12-0010 | 00000000 | 0000 |

| Blade Release Shaft Assembly | 31-52-0066 | 00000000 | 0000 |

| Brush Assembly | 22-18-0025 | 00000000 | 0000 |

| Bumper | 42-18-0035 | 00000000 | 00000 |

| Front Guide Assembly | 42-24-0015 | 00000000 | 00000 |

| Front Handle | 31-44-0740 | 00000000 | 0000 |

| Rear Guide Assembly | 42-28-0025 | 00000000 | 00000 |

For No. 6238-20/6238-21 | |||

| Cord Set | 22-64-0465 | 00000000 | 00000 |

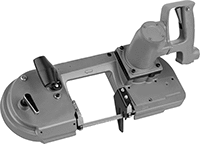

Electric Portable Band Saws

All you need is an outlet to get these band saws moving. Use them to make straight or curved cuts in metal and other materials. They are smaller and more mobile than stationary band saws. When it’s time to switch out the blade, you won’t need any tools.

Saws with an adjustable shoe stabilize your workpiece and hold it in place.

Adjust the speed on saws with speed control based on the hardness of your material. Set the dial to your desired speed, then make small tweaks using the trigger—the harder you squeeze it, the faster the blade will move. These saws also have an LED light to see where you’re cutting.

Band saw stands (sold separately) transform your portable band saw into a stationary one. Attach these stands to a benchtop or add legs with 3/4 NPT pipe, so you can work at a comfortable height anywhere in your facility. They have a chain vise to hold your material.

Saws | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Cutting | For Blade | Stands | |||||||||||||||

| Current | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Blade Included | Overall Lg. | Wt., lbs. | Features | Specifications Met | Includes | Each | Each | ||

Milwaukee 6238-20/6238-21 | |||||||||||||||||

| 11 A @ 120 V AC | 5" | 5" | 5" | 300, 380 | 44 7/8" | 1/2" | 0.02" | No | 21" | 14.5 | Adjustable Shoe | UL Listed, C-UL Listed, CSA Certified, OSHA Compliant 29 CFR 1910.243, OSHA Compliant 29 CFR 1926.302 | Plastic Case | 00000000 | 0000000 | 00000000 | 0000000 |

Milwaukee 6232-20/6232-21 | |||||||||||||||||

| 11 A @ 120 V AC | 5" | 5" | 5" | 0-380 | 44 7/8" | 1/2" | 0.02" | No | 21" | 14.5 | Adjustable Shoe, Speed Control, LED Light | UL Listed, C-UL Listed, CSA Certified, OSHA Compliant 29 CFR 1910.243, OSHA Compliant 29 CFR 1926.302 | Plastic Case | 00000000 | 000000 | 00000000 | 000000 |

DeWalt DWM120 | |||||||||||||||||

| 10 A @ 120 V AC | 5" | 5" | 4 3/4" | 100-350 | 44 7/8" | 1/2" | 0.02" | Yes | 21" | 15 | Speed Control, LED Light | UL Listed, CSA Certified | __ | 0000000 | 000000 | 000000 | 00 |

Replacement Parts for DeWalt Portable Band Saws

Cordless Band Saws

Make straight or curved cuts in metal, plastic, and wood anywhere on your site. These band saws give you the same cutting power as an electric portable band saw but don’t need an outlet. More powerful than our compact cordless band saws, they’re able to cut through thicker materials. Use them to slice through strut channel, conduit, and pipe. The more you squeeze their trigger, the faster the blade moves. Slow down the blade for hard materials and speed it up for soft ones. No tools are necessary to switch out the blade.

Some saws include rechargeable batteries. For other saws, batteries and chargers are sold separately.

For smoother cuts in thick and hard materials, choose a saw with higher voltage.

Fine-tune the speed on saws with speed control based on the hardness of your material. When you fully depress the trigger, these saws run at the maximum speed you set.

Saws with an adjustable shoe let you change your cutting depth without needing tools. The less exposed the blade is, the more stable it is for straight cuts.

Saws with a brake come to a stop when you release the trigger, so you can quickly reposition your tool and move to your next cut.

Saws with a cut brake stop automatically when there's nothing more to cut through. Especially useful in tight spaces, this brake helps prevent accidental nicks to nearby material.

Max. Cutting | For Blade | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturer Model No. | Voltage | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Blade Included | Overall Lg. | Wt., lbs. | Batteries Included | Battery Charger Included | Includes | Features | Cannot Be Sold To | Each | |

DeWalt | ||||||||||||||||||

| DCS374B | 20V DC | 5" | 5" | 5" | 490 | 44 7/8" | 1/2" | 0.02" | No | 20 1/2" | 12.4 | No | No | __ | LED Light, Speed Control | __ | 00000000 | 0000000 |

| DCS378B | 20V DC | 3 3/8" | 3 3/8" | 3 3/8" | 570 | 35 3/8" | 1/2" | 0.02" | Yes | 16 1/2" | 8.4 | No | No | One 35 3/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (18 Teeth per Inch) | LED Light, Speed Control | __ | 00000000 | 000000 |

| DCS378P1 | 20V DC | 3 3/8" | 3 3/8" | 3 3/8" | 570 | 35 3/8" | 1/2" | 0.02" | Yes | 16 1/2" | 8.4 | Yes | Yes | One 35 3/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (18 Teeth per Inch); Carrying Case | LED Light, Speed Control | __ | 00000000 | 000000 |

Makita | ||||||||||||||||||

| GBP01M1 | 40V DC | 5" | 5" | 5" | 630 | 44 7/8" | 1/2" | 0.02" | Yes | 15" | 17.9 | Yes | Yes | One 44 7/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (10 Teeth per Inch); Carrying Case | Adjustable Shoe, Brake, LED Light, Speed Control | Outside United States | 00000000 | 000000 |

| GBP01Z | 40V DC | 5" | 5" | 5" | 630 | 44 7/8" | 1/2" | 0.02" | Yes | 15" | 17.9 | No | No | One 44 7/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (10 Teeth per Inch) | Adjustable Shoe, Brake, LED Light, Speed Control | Outside United States | 00000000 | 000000 |

Milwaukee | ||||||||||||||||||

| 2829-20 | 18V DC | 3 1/4" | 3 1/4" | 3 1/4" | 540 | 35 3/8" | 1/2" | 0.02" | Yes | 18" | 7.7 | No | No | One 35 3/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (8-10 Teeth per Inch) | Adjustable Shoe, LED Light | __ | 00000000 | 000000 |

| 2829-22 | 18V DC | 3 1/4" | 3 1/4" | 3 1/4" | 540 | 35 3/8" | 1/2" | 0.02" | Yes | 18" | 7.7 | Yes | Yes | One 35 3/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (8-10 Teeth per Inch); Carrying Case | Adjustable Shoe, LED Light | __ | 00000000 | 000000 |

| 2929-20 | 18V DC | 5" | 5" | 5" | 550 | 44 7/8" | 1/2" | 0.02" | Yes | 21" | 10.5 | No | No | One 44 7/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood | Adjustable Shoe, Cut Brake, LED Light, Speed Control | __ | 00000000 | 000000 |

| 2929-22 | 18V DC | 5" | 5" | 5" | 550 | 44 7/8" | 1/2" | 0.02" | Yes | 21" | 10.5 | Yes | Yes | One 44 7/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood; Plastic Case | Adjustable Shoe, Cut Brake, LED Light, Speed Control | __ | 0000000 | 000000 |

Compact Cordless Band Saws

Weighing under 8 lbs. and small enough to handle with one hand, these saws are perfect for cutting overhead or in tight spaces. They give you the same power as electric portable band saws without needing access to an outlet. Use them to make precise straight and curved cuts in metal, plastic, and wood.

The more you squeeze their trigger, the faster the blade moves. Slow down the blade for hard materials and speed it up for soft materials. No tools are necessary to switch out the blade.

Some saws include rechargeable batteries. For other saws, batteries and chargers are sold separately.

DeWalt and Makita saws have speed control, so you can set a maximum speed based on the hardness of your material. Makita saws also have a brake that stops the blade when you release the trigger, so you can quickly reposition your tool and move to your next cut.

Max. Cutting | For Blade | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manufacturer Model No. | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Overall Lg. | Wt., lbs. | Batteries Included | Battery Charger Included | Specifications Met | Includes | Features | Cannot Be Sold To | Each | |

DeWalt—20V DC | |||||||||||||||||

| DCS377B | 1 3/4" | 1 3/4" | 1 3/4" | 0-380 | 27 1/4" | 1/2" | 0.02" | 12 1/2" | 6.6 | No | No | __ | One 27 1/4" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (18 Teeth per Inch) | LED Light, Speed Control | __ | 00000000 | 0000000 |

| DCS377Q1 | 1 3/4" | 1 3/4" | 1 3/4" | 0-380 | 27 1/4" | 1/2" | 0.02" | 12 1/2" | 6.6 | Yes | Yes | __ | One 27 1/4" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (18 Teeth per Inch); Carrying Case | LED Light, Speed Control | __ | 00000000 | 000000 |

Makita—18V DC | |||||||||||||||||

| XBP04Z | 2 5/8" | 2 5/8" | 2 5/8" | 0-630 | 32 7/8" | 1/2" | 0.02" | 15 1/2" | 7.9 | No | No | __ | One 32 7/8" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (18 Teeth per Inch) | Electric Brake, LED Light, Speed Control | Outside United States | 00000000 | 000000 |

Milwaukee—12V DC | |||||||||||||||||

| 2429-21XC | 1 5/8" | 1 5/8" | 1 5/8" | 0-280 | 27 1/4" | 1/2" | 0.02" | 12" | 6.8 | Yes | Yes | OSHA Compliant 29 CFR 1910.243, OSHA Compliant 29 CFR 1926.302, UL Listed, C-UL Listed | One 27 1/4" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (18 Teeth per Inch); Plastic Case | LED Light | __ | 0000000 | 000000 |

| 2529-20 | 2 1/2" | 2 1/2" | 2 1/2" | 0-570 | 30 9/16" | 1/2" | 0.02" | 14" | 6 | No | No | OSHA Compliant 29 CFR 1910.243, UL Listed, C-UL Listed | One 30 9/16" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (12-14 Teeth per Inch) | LED Light | __ | 00000000 | 000000 |

| 2529-21XC | 2 1/2" | 2 1/2" | 2 1/2" | 0-570 | 30 9/16" | 1/2" | 0.02" | 14" | 6 | Yes | Yes | OSHA Compliant 29 CFR 1910.243, UL Listed, C-UL Listed | One 30 9/16" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal, Plastic, and Wood (12-14 Teeth per Inch); Carrying Case | LED Light | __ | 00000000 | 000000 |

Air-Powered Portable Band Saws

Make straight and curved cuts through dense and hard material without your blade stalling out. Powered by air, these saws maintain their speed better than electric and battery-powered saws while cutting through tough workpieces. In addition to wood and plastic, they’re often used on metal parts such as steel pipes and stainless steel strut channels. Unlike stationary band saws, you can bring them right to your workpiece. Switch the blade out without an L-key or screwdriver thanks to the tool-free blade change system.

Max. Cutting | Blade | Air Inlet | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Air Consumption, cfm | Recommended Operating Air Pressure, psi | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Pipe Size | Thread Type | Gender | For Air Hose ID | Exhaust Location | Overall Lg. | Wt., lbs. | Each | |

| 0.7 | 20 | 90 | 4" | 4 3/4" | 4 1/2" | 130-195 | 44 7/8" | 1/2" | 0.02" | 1/4 | NPT | Female | 3/8" | Side | 21 1/2" | 14 | 0000000 | 000000000 |

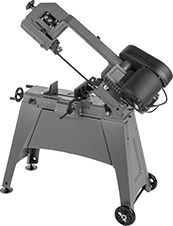

Bench-Top Band Saws for Metal

Save space with these saws when you only need to make cuts in small pieces of metal. For smoother cuts in thick and hard metals, choose a saw with higher horsepower (hp). Saws with higher horsepower also handle continuous use better. These band saws are only for dry cutting.

Horizontal-blade saws—roughly the size of a microwave—are for accurate straight or angled cuts, such as miter cuts. Since you lower the blade onto your clamped material, these saws work well for repeat cuts. They’re often used on pipes, bars, blocks, and I-beams. Adjusting the blade guides for accurate and stable cutting doesn’t require any tools. Use a work table (sold separately) to convert these saws into vertical band saws. Saws with clockwise blade rotation have more torque to cut through material faster than standard band saws, whose blades move counterclockwise. As you cut, metal shards move away from your material, reducing heat buildup and extending blade life.

Vertical-blade saws—roughly the size of a mini-fridge—are for curved, detailed, and intricate cuts. If you use a fence as a guide, these saws can also make straight cuts in long pieces of material. Connect the chip collection port to a dust collector to keep your work area clean. These saws are compatible with replacement blades between 67”-68” long.

Saws with an automatic feed system control the saw head speed for a consistent cut every time. Once the blade reaches your material, the weight of the saw head completes the cut for you, reducing fatigue.

Saws | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Cutting | Blade | Overall | 12 3/4" Lg. × 11 3/4" Wd. Work Tables | ||||||||||||||

| Power, hp | Current | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Features | Each | Each | ||

Manual Feed System | |||||||||||||||||

| 1.3 | 9 A @ 120 V AC | 4" | 3 3/4" | 3 1/4" | 45° (Left) | 135, 265 | 52 1/2" | 1/2" | 0.025" | 33 1/2" | 14 1/4" | 25 3/4" | Tool-Free Adjustable Blade Guide | 0000000 | 0000000 | 0000000 | 0000000 |

| 1.7 | 5 A @ 120 V AC | 4 1/2" | 4 1/2" | 4" | 60° (Left) | 115-262 | 56 3/4" | 1/2" | 0.025" | 33 1/2" | 32 3/4" | 23 3/4" | Clockwise Blade Rotation, Tool-Free Adjustable Blade Guide | 0000000 | 00000000 | 000000 | 00 |

Automatic Feed System | |||||||||||||||||

| 1.7 | 11.8 A @ 120 V AC | 4 1/2" | 4 1/2" | 4" | 60° (Left) | 114-262 | 56" | 1/2" | 0.025" | 32" | 32" | 27" | Automatic Shut-Off, Clockwise Blade Rotation, Tool-Free Adjustable Blade Guide | 00000000 | 00000000 | 000000 | 00 |

Max. Cutting | Blade | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Current | Dia. | Dp. | Ht. | Work Table Tilt Angle (Tilt Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Features | Each | |

Manual Feed System | |||||||||||||||

| 1/3 | 3.5 A @ 120 V AC | 4" | 9 1/2" | 4" | 45° (Right) | 250, 350, 450 | 67 3/8" | 1/2" | 0.025" | 21" | 16 1/2" | 34" | Chip Collection Port | 00000000 | 0000000 |

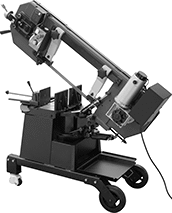

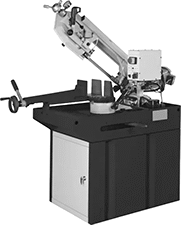

Adjustable Band Saws for Metal

Highly versatile, these saws make precise horizontal and vertical cuts from a single saw. They work well whether you’re simply cutting metal into smaller pieces or creating complex shapes. When the blade is horizontal, these saws cut from above, making square or angled cuts. For straight or intricate curved cuts, position the blade vertically and feed your workpiece through. They’re powerful enough to cut through aluminum, steel, and stainless steel. However, they should only be used for dry cutting.

The higher the horsepower, the smoother the cut, even in thick and hard metals.

Direct-drive saws send power straight to the blade instead of a belt, which keeps power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Saws with an automatic feed push material into the blade at a steady pace, so they’re more accurate than those you feed manually. Once the blade reaches your material, the weight of the saw head completes the cut for you.

Max. Cutting | Blade | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Drive Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | No. of Wheels | Each | |

Manual Feed System | |||||||||||||||||

| 5 A @ 120 V AC | 1 1/4 | Direct | 10" | 8" | 10" | 45° (Left/Right) | 65-250 | 118" | 1" | 0.035" | 60" | 24" | 50" | 560 | 4 | 00000000 | 000000000 |

| 8 A @ 120 V AC 4 A @ 240 V AC | 1/2 | Belt | 5" | 5" | 5 3/4" | 45° (Left) | 80, 120, 200 | 64 1/2" | 1/2" | 0.025" | 36" | 20" | 39 1/2" | 115 | 2 | 0000000 | 000000 |

Automatic Feed System | |||||||||||||||||

| 20 A @ 120 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

| 20 A @ 120 V AC 20 A @ 240 V AC | 1 | Belt | 10" | 7" | 9" | 45° (Left/Right) | 70, 135, 250 | 120" | 1" | 0.037" | 59 1/4" | 24 3/4" | 47" | 475 | 2 | 0000000 | 00000000 |

| 20 A @ 240 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

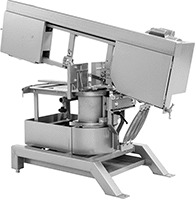

Horizontal Band Saws for Metal

Make repeat cuts in pipes, bars, and thick metal sheets. These saws make more precise straight and angled cuts than vertical band saws by cutting from above into a clamped workpiece. For smooth cuts every time, the saw head uses hydraulics to move at a controlled speed. Once the blade reaches your material, the weight of the saw head completes the cut for you. The built-in coolant system prevents overheating, so the blade lasts longer and your workpiece won’t harden or warp. The coolant also keeps the cut area clear of metal shards to stop them from sticking onto the blade.

Direct-drive saws send power straight to the blade instead of a belt, which keeps the power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Saws with automatic shut-off stop when there's nothing more to cut through to avoid running needlessly or nicking nearby material.

Saws with cutting resistance detection automatically adjust their speed to protect the blade from bending and the teeth from chipping. The blade slows down for hard materials and speeds up for soft ones. Since you don’t need any tools to access the blade, swapping it out is quick and easy.

Saws with blade tension detection prevent startup if the blade is loose, misaligned, or broken. As a fail-safe, they can also stop mid-cut.

Max. Cutting | Blade | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Feed System Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | No. of Wheels | Features | Each | |

Belt Drive | ||||||||||||||

Single Phase—Three-Prong Plug | ||||||||||||||

| 12 A @ 120 V AC 6 A @ 240 V AC | 1 | Automatic | 7" | 12" | 7" | 45° (Left/Right) | 96, 132, 178, 260 | 93" | 3/4" | 0.035" | 4 | Automatic Shut-Off Quick-Release Vise | 0000000 | 000000000 |

Direct Drive | ||||||||||||||

Single Phase—Three-Prong Plug | ||||||||||||||

| 9 A @ 120 V AC | 1 1/2 | Automatic | 8 5/8" | 9" | 8 5/8" | 60° (Left/Right) | 115-230 | 97" | 1" | 0.035" | 0 | Blade Tension Detection Quick-Release Vise | 0000000 | 00000000 |

| 13 A @ 120 V AC | 1 1/2 | Automatic, Manual | 9" | 16" | 9" | 45° (Left) 60° (Right) | 98-262 | 131 1/2" | 1" | 0.035" | 0 | Cutting Resistance Detection Front Blade Access Quick-Release Vise Removable Chip Tray Removable Coolant Tank | 0000000 | 00000000 |

Bench-Top Band Saws for Ceramics and Masonry

The grinding action of the diamond-grit blade creates a smooth finish on hard materials such as glass, stone, tile, brick, and fiberglass. This saw is not for cutting metal. It makes straight and curved cuts. A recirculating tap water coolant system extends blade life.

Max. Cutting | For Blade | Overall | Table | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | Dp. | Wd. | Includes | Each | |

| 1 A @ 120 V AC | 3 3/4" | 5 1/2" | 3 1/2" | 3,520 | 37" | 9/64" | 0.02" | 13" | 14" | 17" | 18 | 12" | 12" | One 37" Lg. × 9/64" Wd. Diamond Grit Blade for Ceramics and Masonry | 00000000 | 0000000 |

Anti-Vibration Portable Band Saw Blades

Also known as variable-set blades, these have teeth that vary in size, number per inch, and pattern to reduce vibration so they create a smoother cut than Portable Band Saw Blades. These bimetal blades have a flexible carbon steel body and high-speed steel teeth. Choose blades with more teeth per inch for a smooth finish; choose blades with fewer teeth per inch for fast, rough cutting. All blades have a welded seam and are ready to install on your saw.

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Teeth per Inch | For Material Thick. | For Use On | Tooth Style | Body | Tooth | Pkg. Qty. | Each | |

1/2" Wd. × 0.02" Thick. | |||||||||

| 27 3/16" | 12-16 | 3/8"-2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 28 13/16" | 12-16 | 3/8"-2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| Pkg. | |||||||||

| 30 9/16" | 8-11 | 1/2"-3" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| 30 9/16" | 12-16 | 3/8"-2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| Each | |||||||||

| 32 7/8" | 8-11 | 1/2"-3" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 35 3/8" | 8-11 | 1/2"-3" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 00000000 | 0000 |

| 35 3/8" | 10-14 | 1/4"-1/2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

| Pkg. | |||||||||

| 35 3/8" | 12-16 | 3/8"-2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| Each | |||||||||

| 44 7/8" | 8-11 | 1/2"-3" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 44 7/8" | 10-14 | 1/4"-1/2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| Pkg. | |||||||||

| 44 7/8" | 12-16 | 3/8"-2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| Each | |||||||||

| 53 3/4" | 10-14 | 1/4"-1/2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

Portable Band Saw Blades

Designed for use with portable band saws, these blades are shorter and lighter in weight than standard band saw blades. They're also better for jobs in tight spaces, such as cutting metal channel that's already installed. Also known as bimetal blades, they have high-speed steel teeth and a flexible steel body. This flexibility makes them suitable for both straight and curved cuts. Tooth size and number per inch are constant throughout the blade.

Choose blades with more teeth per inch for a smooth finish; choose blades with fewer teeth per inch for fast, rough cutting. All blades have a welded seam and are ready to install on your saw.

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Teeth per Inch | For Material Thick. | For Use On | Tooth Style | Body | Tooth | Pkg. Qty. | Pkg. | |

1/2" Wd. × 0.02" Thick. | |||||||||

| 32 7/8" | 14 | 3/16"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | 3 | 0000000 | 000000 |

| Each | |||||||||

| 35 3/8" | 10 | 5/16"-1/2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 35 3/8" | 14 | 3/16"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 44 7/8" | 10 | 1/2"-1" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 44 7/8" | 14 | 3/16"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 53 3/4" | 10 | 1/2"-1" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 53 3/4" | 14 | 3/16"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

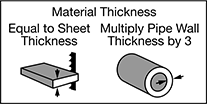

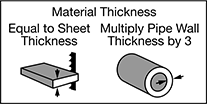

Portable Band Saw Blades for Thin Metal

Slice through thin metal with your portable band saw. These blades are lighter and shorter than standard band saw blades, so they’re easier to move around a job site. Often used on steel channel or thin-walled pipe that’s already installed, they can make cuts in tight spaces. Also known as bimetal blades, these blades have high-speed steel teeth and a flexible steel body. This flexibility makes them suitable for both straight and curved cuts. Tooth size and number per inch are constant throughout the blade.

Choose blades with more teeth per inch for a smooth cut; choose blades with fewer teeth per inch for fast, rough cutting. All blades have a welded seam and are ready to install on your saw.

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Teeth per Inch | For Material Thick. | For Use On | Tooth Style | Body | Tooth | Pkg. Qty. | Each | |

1/2" Wd. × 0.02" Thick. | |||||||||

| 27 1/4" | 18 | Up to 1/4" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 000000 |

| Pkg. | |||||||||

| 28 13/16" | 18 | Up to 1" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| 32 7/8" | 24 | Up to 1/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | 3 | 0000000 | 00000 |

| Each | |||||||||

| 35 3/8" | 18 | Up to 1/4" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 35 3/8" | 24 | Up to 1/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | __ | 0000000 | 00000 |

| 44 7/8" | 18 | Up to 1/4" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 44 7/8" | 24 | Up to 1/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |

| 53 3/4" | 18 | Up to 1/4" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 00000 |

| Pkg. | |||||||||

3/4" Wd. × 0.02" Thick. | |||||||||

| 32 7/8" | 18 | Up to 1/2" | Steel, Stainless Steel, Aluminum, Brass, Bronze, Wood, Plastic | Constant Set | Steel | High-Speed Steel | 3 | 0000000 | 00000 |

Anti-Vibration Portable Band Saw Blades for Thin Metal

Improve accuracy, increase stability, and reduce noise while cutting with a portable band saw—the teeth on these blades vary in size, number per inch, and pattern to reduce vibration. They’re also known as variable-set blades. Lighter and shorter than standard band saw blades, they’re easier to move around your workspace. Use them for cutting metal sheets, channels, and conduit, as well as thin-walled pipe. Sometimes referred to as bimetal blades, they have high-speed steel teeth and a flexible steel body. This flexibility makes them suitable for both straight and curved cuts. All blades have a welded seam and are ready to install on your saw.

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lg. | Teeth per Inch | For Material Thick. | For Use On | Tooth Style | Body | Tooth | Pkg. Qty. | Pkg. | |

1/2" Wd. × 0.02" Thick. | |||||||||

| 27 3/16" | 14-18 | 1/4"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze | Variable Set | Carbon Steel | High-Speed Steel | 3 | 00000000 | 000000 |

| 28 13/16" | 14-18 | 1/4"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze | Variable Set | Carbon Steel | High-Speed Steel | 3 | 00000000 | 00000 |

| 32 7/8" | 14-18 | 1/4"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze | Variable Set | Carbon Steel | High-Speed Steel | 3 | 00000000 | 00000 |

| 35 3/8" | 14-18 | 1/4"-3/8" | Steel, Stainless Steel, Aluminum, Brass, Bronze | Variable Set | Carbon Steel | High-Speed Steel | 3 | 00000000 | 00000 |

| Each | |||||||||

| 44 7/8" | 14-18 | 1/8"-1/4" | Steel, Stainless Steel, Aluminum, Brass, Bronze | Variable Set | Carbon Steel | High-Speed Steel | __ | 0000000 | 0000 |