About Selecting a Vibrator

More

Portable Magnetic-Mount Air-Powered Vibrators for Dry Materials

Move this vibrator to the source of your flow problem. It is lightweight and has a magnetic mount, so it can be attached to steel and iron containers. Use an adhesive-back metal pad (sold separately) to attach it to nonferrous containers. This vibrator is often used to shake powders, grains, and small parts to maintain a steady flow through your bin. Every 10 pounds of dry material requires one pound of force to move it. If your bin has 200 pounds of dry material, you need a vibrator with at least 20 pounds of force.

Inlet Air Connection | Overall Size | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Content Weight, lbs. | Force @ 60 psi, lbs. | Vibrations per Minute @ 60 psi | Pipe Size | Thread Type | Gender | Air Consumption @ 60 psi, cfm | Volume @ 60 psi, dBA | Wt., lbs. | Wd. | Ht. | Dp. | Each | |

| 250 | 25 | 3,500 | 1/4 | NPT | Female | 2.5 | 85 | 4 | 1 15/16" | 7 1/2" | 1 15/16" | 0000000 | 000000000 |

| Material | Dia. | Each | |

| Steel | 4" | 0000000 | 0000000 |

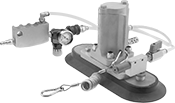

Vacuum-Mount Air-Powered Vibrators for Wet Materials

These vibrators attach more quickly than other vibrators by generating a vacuum instead of bolting or welding, so you can place them at the source of the blockage and quickly move them between bins. They're often used to dislodge sticky, caked-on materials from trailers, railcars, and hoppers. Bin wall thickness determines the force required to move the material in the bin. To select a vibrator strong enough for your application, find your bin's wall thickness in the table.

Inlet Air Connection | Outlet Air Connection | Overall Size | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Wall Thick. | Force @ 80 psi, lbs. | Vibrations per Minute @ 80 psi | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Air Consumption @ 80 psi, cfm | Volume @ 80 psi, dBA | Ht. | Wd. | Dp. | Each | |

| 1/8" | 260 | 5,300 | 1/4 | NPT | Female | 1/4 | NPT | Female | 8.0 | 86 | 6 3/4" | 11 5/8" | 4 3/8" | 0000000 | 000000000 |

| 3/16" | 490 | 2,900 | 1/4 | NPT | Female | 1/4 | NPT | Female | 17.5 | 90 | 8 9/16" | 19 5/16" | 6 3/8" | 0000000 | 00000000 |

Bracket-Mount Air-Powered Vibrators for Wet Materials

Weld a bracket to each of your containers and move these vibrators from job to job. They're commonly used to dislodge sticky, caked-on materials from container walls. Bin wall thickness determines the force required to move the material in the bin. To select a vibrator strong enough for your application, find your bin's wall thickness in the table.

Vibrators | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Air Connection | Outlet Air Connection | Overall Size | Required Weld-On Brackets | ||||||||||||

| Force @ 80 psi, lbs. | Vibrations per Minute @ 80 psi | For Wall Thick. | Pipe Size | Thread Type | Pipe Size | Thread Type | Air Consumption @ 80 psi, cfm | Volume @ 80 psi, dBA | Ht. | Wd. | Dp. | Each | Each | ||

| 326 | 5,900 | 1/8" | 1/4 | NPT | 1/4 | NPT | 7.0 | 95 | 5" | 7 1/16" | 3" | 0000000 | 0000000 | 0000000 | 000000 |

| 610 | 3,300 | 1/4" | 1/4 | NPT | 1/4 | NPT | 15.8 | 99 | 7 1/2" | 10 1/4" | 5 1/2" | 0000000 | 000000 | 0000000 | 000000 |

| 1,917 | 3,000 | 3/8" | 3/8 | NPT | 3/8 | NPT | 21.0 | 102 | 11 1/2" | 13 9/16" | 6" | 0000000 | 00000000 | 0000000 | 000000 |

| 2,422 | 2,600 | 3/8" | 1/2 | NPT | 1/2 | NPT | 33.0 | 104 | 11 1/2" | 15 1/4" | 6" | 0000000 | 00000000 | 0000000 | 000000 |