Filter by

Finish

Head Finish

Thread Size

Shank Length

Body Style

Length

Eye Diameter

Thread Length

Mount Type

Movement

Eye Type

Threading

Application

Fastener Head Type

Magnetic Pull Rating

Overall Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

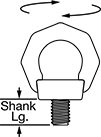

Rotating Eyebolts—For Lifting

Powder-Coated Steel

|  |

Thread | With Shoulder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Shank Lg. | Eye Dia. | Vert. Cap., lb. | Threading | Color | Overall Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 15/32" | 15/32" | 1" | 650 | Fully Threaded | Pink | 2 1/4" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 9/16" | 9/16" | 1" | 875 | Fully Threaded | Pink | 2 1/4" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 19/32" | 19/32" | 1" | 850 | Fully Threaded | Pink | 2 3/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 11/16" | 11/16" | 1 3/16" | 1,650 | Fully Threaded | Pink | 2 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 15/16" | 15/16" | 1 3/8" | 3,300 | Fully Threaded | Pink | 3 1/2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 3/16" | 1 3/16" | 1 9/16" | 5,050 | Fully Threaded | Pink | 4 1/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 1 5/32" | 1 5/32" | 1 9/16" | 5,050 | Fully Threaded | Pink | 4 1/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 1 3/8" | 1 3/8" | 1 7/8" | 7,050 | Fully Threaded | Pink | 5" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-7 | 1 27/64" | 1 27/64" | 1 15/16" | 7,050 | Fully Threaded | Pink | 4 7/8" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-8 | 1 13/32" | 1 13/32" | 1 29/32" | 7,050 | Fully Threaded | Pink | 5" | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 1 3/4" | 1 3/4" | 2 3/8" | 9,900 | Fully Threaded | Pink | 6 1/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-6 | 2 1/8" | 2 1/8" | 2 13/16" | 15,425 | Fully Threaded | Pink | 7 3/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-4 1/2 | 2 13/16" | 2 13/16" | 3 11/16" | 26,450 | Fully Threaded | Pink | 9 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9 mm | 9 mm | 20 mm | 200 | Fully Threaded | Pink | 46 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 12 mm | 12 mm | 25 mm | 650 | Fully Threaded | Pink | 58 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 mm | 15 mm | 25 mm | 850 | Fully Threaded | Pink | 61 mm | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 18 mm | 18 mm | 30 mm | 1,650 | Fully Threaded | Pink | 73 mm | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 2 mm | 18 mm | 18 mm | 30 mm | 1,650 | Fully Threaded | Pink | 73 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 24 mm | 24 mm | 35 mm | 3,300 | Fully Threaded | Pink | 88 mm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 2.5 mm | 24 mm | 24 mm | 35 mm | 3,300 | Fully Threaded | Pink | 88 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 30 mm | 30 mm | 40 mm | 5,050 | Fully Threaded | Pink | 104 mm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 36 mm | 36 mm | 48 mm | 7,050 | Fully Threaded | Pink | 127 mm | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M27 × 3 mm | 36 mm | 36 mm | 49 mm | 7,050 | Fully Threaded | Pink | 126 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 × 3.5 mm | 45 mm | 45 mm | 60 mm | 9,900 | Fully Threaded | Pink | 158 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M36 × 4 mm | 54 mm | 54 mm | 73 mm | 15,400 | Fully Threaded | Pink | 190 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M48 × 5 mm | 72 mm | 72 mm | 96 mm | 26,450 | Fully Threaded | Pink | 252 mm | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

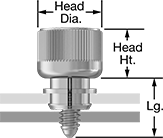

Snap-In Captive Panel Screws

Head | Black Powder-Coated Aluminum Head | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Outer Panel Thk. | For Outer Panel Hole Dia. | Dia. | Ht. | Lg. | Screw Material | 1-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6-32 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" to 0.039" | 0.25" | 0.45" | 0.42" | 0.22" | 400 Series Stainless Steel | 000000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" to 0.039" | 0.25" | 0.45" | 0.42" | 0.28" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" to 0.039" | 0.25" | 0.45" | 0.42" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" to 0.063" | 0.25" | 0.45" | 0.42" | 0.29" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" to 0.063" | 0.25" | 0.45" | 0.42" | 0.35" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" to 0.063" | 0.25" | 0.45" | 0.42" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8-32 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" to 0.063" | 0.25" | 0.51" | 0.44" | 0.35" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.063" to 0.098" | 0.25" | 0.51" | 0.44" | 0.35" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.063" to 0.098" | 0.25" | 0.51" | 0.44" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.098" to 0.125" | 0.25" | 0.51" | 0.44" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-32 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.039" to 0.063" | 0.25" | 0.51" | 0.44" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.063" to 0.098" | 0.25" | 0.51" | 0.44" | 0.35" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.063" to 0.098" | 0.25" | 0.51" | 0.44" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.098" to 0.125" | 0.25" | 0.51" | 0.44" | 0.41" | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M3.5 × 0.6 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm to 1 mm | 6.4 mm | 11.5 mm | 10.6 mm | 5.6 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 11.5 mm | 10.6 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm to 1 mm | 6.4 mm | 13 mm | 11.3 mm | 5.6 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm to 1 mm | 6.4 mm | 13 mm | 11.3 mm | 7.2 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 mm to 1 mm | 6.4 mm | 13 mm | 11.3 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 7.2 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 8.8 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm to 2.5 mm | 6.4 mm | 13 mm | 11.3 mm | 7.2 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm to 2.5 mm | 6.4 mm | 13 mm | 11.3 mm | 8.8 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm to 2.5 mm | 6.4 mm | 13 mm | 11.3 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M5 × 0.8 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 7.2 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 8.8 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm to 1.6 mm | 6.4 mm | 13 mm | 11.3 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm to 2.5 mm | 6.4 mm | 13 mm | 11.3 mm | 8.8 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm to 2.5 mm | 6.4 mm | 13 mm | 11.3 mm | 10.4 mm | 400 Series Stainless Steel | 000000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

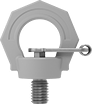

Encased Ceramic Disc Magnets

Magnets With Threaded Stud

Style | Thk. | OD | Stud Lg. | Overall Lg. | Max. Pull, lbf | Max. Temp., ° F | Magnet Grade | Thread Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Powder-Coated Steel Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 5/16" | 63/64" | 0.413" | 47/64" | 4 | 120 | C8 | 10-24 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 5/16" | 1 17/64" | 0.413" | 47/64" | 9 | 120 | C8 | 1/4"-20 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 23/64" | 1 21/32" | 1/2" | 55/64" | 21 | 120 | C8 | 5/16"-18 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 29/64" | 1 57/64" | 1/2" | 61/64" | 29 | 120 | C8 | 5/16"-18 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 1/2" | 2" | 1/2" | 1" | 48 | 120 | C8 | 1/4"-20 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 5/8" | 2 1/2" | 0.846" | 1 15/32" | 60 | 120 | C8 | 3/8"-16 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 49/64" | 3" | 0.87" | 1 5/8" | 110 | 120 | C8 | 3/8"-16 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 8 mm | 25 mm | 8 mm | 16 mm | 4 | 120 | C8 | M5 × 0.8 mm | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 8 mm | 32 mm | 10 mm | 18 mm | 9 | 120 | C8 | M6 × 1 mm | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 9 mm | 42 mm | 10 mm | 19 mm | 21 | 120 | C8 | M6 × 1 mm | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 11.5 mm | 48 mm | 10 mm | 21.5 mm | 29 | 120 | C8 | M8 × 1.25 mm | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 13 mm | 50.8 mm | 10 mm | 23 mm | 48 | 120 | C8 | M8 × 1.25 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 16 mm | 63.5 mm | 11.5 mm | 27.5 mm | 60 | 120 | C8 | M8 × 1.25 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 19 mm | 76.2 mm | 15 mm | 34 mm | 110 | 120 | C8 | M10 × 1.5 mm | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||