Filter by

For Use With

Fitting Connection

System of Measurement

Body Material

Outlet Pressure

Inlet Connection

Outlet Connection

Maximum Inlet Pressure

Thread Type

Environment

Material

Gender

Gasket Material

DFARS Specialty Metals

Sanitary Gauge Guards

316 Stainless Steel Body

Outlet Quick-Clamp Tube Connection | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Connection | For Tube OD | Flange OD | Gasket Material | For Use With | Min. Pressure, psi | Max. Pressure @ Temp. | Max. Temp. | Ht. | Interior Smoothness, Ra | Each | ||

| 1/4 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 0000000 | |

| 1/4 NPT Female | 2" | 2.516" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 1/8" | 32 | 0000000 | 000000 | |

| 1/2 NPT Female | 1 1/2" | 1.984" | 316 Stainless Steel | Acetylene, Air, Ammonia, Beverage, Boric Acid, Carbon Dioxide, Diesel Fuel, Ethanol, Food, Gasoline, Hydraulic Fluid, Hydrogen, Oxygen, Pharmaceuticals, Wastewater, Water | 30 | Not Rated | Not Rated | 1 3/8" | 32 | 0000000 | 000000 | |

Pressure-Regulating Valves with Push-to-Connect Fittings for Food and Beverage

Inlet | Outlet | Gauge Port | Lg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Location | Max. Pressure, psi | For Tube OD | Location | Pressure Adjustment Method | Pressure Gauge Included | Pipe Size | Location | Connection | End-to-End | Port-to-Port | For Use With | Temp. Range, ° F | Food Industry Std. | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Push-to-Connect Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Noryl PPO Body—Buna-N Diaphragm and Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Side | 300 | 1/4" | Side | Screw | No | 1/4 | Side | NPT Female | 2 13/16" | 1 25/32" | Food, Beverage | 35 to 125 | NSF/ANSI 61 | 0 to 25 , 0 to 60 , 0 to 125 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Regulating Valves with Compression Fittings for Food and Beverage

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Location | Max. Pressure, psi | For Tube OD | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Food Industry Std. | Choose an Outlet Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compression Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Body—Buna-N/Stainless Steel Diaphragm and EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Side | 250 | 1/4" | Side | Knob | 2" | Food, Beverage | 35 to 125 | FDA Compliant 21 CFR 177.2600 | 1 to 10 , 2 to 50 , 5 to 100 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Pressure-Regulating Valves for Food and Beverage

Inlet | Outlet | Gauge Port | Lg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | Pressure Gauge Included | Pipe Size | Location | Connection | End-to-End | Port-to-Port | For Use With | Temp. Range, ° F | Food Industry Std. | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Body—Buna-N/Nylon Diaphragm and EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | Side | 150 | 1/4 | Side | Knob | No | 1/8 | Side | NPT Female | 1 5/8" | 1 1/2" | Food, Beverage | 35 to 125 | FDA Compliant 21 CFR 177.2600, NSF/ANSI 61 | 5 to 50 , 5 to 125 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Noryl PPO Body—Buna-N Diaphragm and Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | Side | 300 | 1/4 | Side | Screw | No | 1/4 | Side | NPT Female | 1 9/16" | 3/4" | Food, Beverage | 35 to 125 | NSF/ANSI 61 | 0 to 25 , 0 to 60 , 0 to 125 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

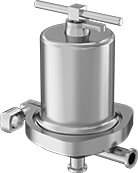

Sanitary Pressure-Regulating Valves

Inlet | Outlet | Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flange OD | Location | Max. Pressure, psi | For Tube OD | Flange OD | Location | Pressure Adjustment Method | End-to-End | Port-to-Port | For Use With | Temp. Range, ° F | Specs. Met | Food Industry Std. | Choose an Outlet Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body—EPDM Diaphragm and Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.984" | Bottom | 200 | 3/4" | 0.984" | Side | T-Handle | 8 5/8" | 3 5/16" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 15 to 50 , 40 to 90 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.984" | Bottom | 200 | 1" | 1.984" | Side | T-Handle | 8 5/8" | 3 5/16" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 5 to 25 , 15 to 50 , 40 to 90 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body—PTFE Diaphragm and EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.984" | Bottom | 125 | 1 1/2" | 1.984" | Side | T-Handle | 13 3/8" | 4 7/32" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 10 to 25 , 15 to 50 , 35 to 100 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.516" | Bottom | 100 | 2" | 2.516" | Side | T-Handle | 16 1/8" | 5 3/4" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 10 to 25 , 15 to 60 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

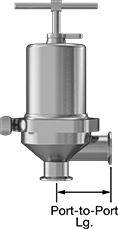

Sanitary Back-Pressure-Regulating Valves

Inlet | Outlet | Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | Flange OD | Location | Max. Pressure, psi | For Tube OD | Flange OD | Location | Pressure Adjustment Method | End-to-End | Port-to-Port | For Use With | Temp. Range, ° F | Specs. Met | Food Industry Std. | Choose an Outlet Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body—EPDM Diaphragm and Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.984" | Side | 200 | 3/4" | 0.984" | Bottom | T-Handle | 6 5/8" | 3 9/32" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 5 to 30 , 35 to 90 , 50 to 105 | 000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.984" | Side | 200 | 1" | 1.984" | Bottom | T-Handle | 6 11/16" | 3 5/16" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 5 to 30 , 35 to 90 , 50 to 105 | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body—PTFE Diaphragm and EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.516" | Side | 100 | 2" | 2.516" | Bottom | T-Handle | 11 5/8" | 5 3/4" | Food, Beverage | -40 to 120 | ANSI/FCI 70-2 Class III | 3-A Certified 64-00, FDA Compliant 21 CFR 177.2600 | 10 to 25 , 15 to 60 | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||