Filter by

System of Measurement

For Use With

Set Pressure

Outlet Pressure

Maximum Inlet Pressure

Airflow Capacity

Inlet Thread Type

Steam Flow Capacity

Set Pressure Configuration

Burst Pressure

Inlet Connection

Outlet Pipe Size

Maximum Temperature

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Remote-Discharge ASME-Code Fast-Acting Pressure-Relief Valves for Air and Inert Gas

1 1/4 NPT Male Bottom Inlet × 1 1/2 NPT Female Side Pipe Relief Port

|  |

Valve | Valve With Test Lever |

Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Seal | Body | Temp. Range, ° F | Test Mechanism | Overall Ht. | Valve Type | For Use With | Certification | Choose a Set Pressure, psi | Each | ||

| Brass | Bronze | -60 to 406 | Lever | 9 5/8" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 , 275 , 300 | 0000000 | 0000000 | |

| Brass | Bronze | -15 to 406 | — | 8 5/16" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | |

| Brass | Bronze | -15 to 406 | Lever | 8 3/4" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | |

| Fluoroelastomer | Bronze | -15 to 406 | Lever | 9 5/8" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 , 275 , 300 | 0000000 | 000000 | |

1 1/2 NPT Male Bottom Inlet × 2 NPT Female Side Pipe Relief Port

|  |

Valve | Valve With Test Lever |

Material | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Seal | Body | Temp. Range, ° F | Test Mechanism | Overall Ht. | Valve Type | For Use With | Certification | Choose a Set Pressure, psi | Each | ||

| Brass | Bronze | -60 to 406 | Lever | 10 5/8" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 , 275 , 300 | 0000000 | 0000000 | |

| Brass | Bronze | -15 to 406 | — | 9 7/16" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | |

| Brass | Bronze | -15 to 406 | Lever | 9 3/4" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | |

| Fluoroelastomer | Bronze | -15 to 406 | Lever | 10 5/8" | Pop Safety | Air, Inert Gas | ASME BPVC.VIII | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 105 , 110 , 115 , 120 , 125 , 130 , 135 , 140 , 145 , 150 , 175 , 200 , 225 , 250 , 275 , 300 | 0000000 | 000000 | |

ASME-Code Fast-Acting Pressure-Relief Valves for Steam

NPT Male Inlet and NPT Female Relief Port

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Shape | Overall Ht. | For Use With | Temp. Range, ° F | Test Mechanism | Test Lever Type | Valve Type | Certification | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Brass Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | Bottom | 250 | 1 1/2 | Side | 90° Elbow | 9 5/8" | Steam | -60 to 400 | Lever | — | Pop Safety | ASME BPVC.I | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 125 , 150 , 175 , 200 , 225 , 250 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 250 | 1 1/2 | Side | 90° Elbow | 9 5/8" | Steam | -60 to 400 | Lever | Swivel | Pop Safety | ASME BPVC.I | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 125 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 250 | 2 | Side | 90° Elbow | 10 5/8" | Steam | -60 to 400 | Lever | — | Pop Safety | ASME BPVC.I | 15 , 20 , 25 , 30 , 35 , 40 , 45 , 50 , 55 , 60 , 65 , 70 , 75 , 80 , 85 , 90 , 95 , 100 , 125 , 150 , 175 , 200 , 225 , 250 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ASME-Code Fast-Acting Pressure-Relief Valves for Water

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Port Pipe Size | Port Location | Overall Ht. | Valve Type | Certification | For Use With | Temp. Range, ° F | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Inlet and NPT Female Relief Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—316 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 2 | Side | 13 1/4" | Pop Safety | ASME BPVC.VIII | Water | -60 to 406 | 20 , 30 , 40 , 50 , 60 , 70 , 80 , 90 , 100 , 125 , 150 , 175 , 200 , 225 , 250 , 275 , 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ASME-Code Fast-Acting Pressure-Relief Valves for Hot Water

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Port Pipe Size | Port Location | Overall Ht. | Test Mechanism | Valve Type | For Use With | Certification | Temp. Range, ° F | Choose a Set Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and Relief Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Silicone Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | Bottom | 1 1/2 | Side | 8 3/8" | Lever | Pop Safety | Water | ASME BPVC.IV | 33 to 250 | 30 , 50 , 60 , 75 , 100 , 125 , 150 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 2 | Side | 10 13/16" | Lever | Pop Safety | Water | ASME BPVC.IV | 33 to 250 | 30 , 50 , 60 , 75 , 100 , 125 , 150 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Back-Pressure-Regulating Valves for Water and Oil

Inlet | Outlet | Relief Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | Pipe Size | Location | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron Body—Nickel Diaphragm and 303 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 400 | 1 1/2 | Side | Screw | 1 1/2 | Bottom | 5" | Water, Oil | -40 to 200 | 10 to 55 , 30 to 100 , 40 to 200 , 125 to 300 , 200 to 400 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

ASME-Code Fast-Acting Pressure-Relief Valves for Low-Pressure Steam

90° Elbow

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Type | Gender | Location | Max. Pressure, psi | Port Pipe Size | Port | Port Fitting Connection | Port Thread Type | Port Gender | Port Location | Steam Flow Cap., lb/hr | Set Pressure, psi | Overall Ht. | Test Mechanism | Valve Type | For Use With | Certification | Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—PTFE-Coated EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4 | NPT | Male | Bottom | 15 | 1 1/2 | Pipe | Threaded | NPT | Female | Side | 1,200 | 15 | 4 1/2" | Lever | Pop Safety | Steam | ASME BPVC.IV | 250 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | NPT | Male | Bottom | 15 | 2 | Pipe | Threaded | NPT | Female | Side | 1,900 | 15 | 5 1/4" | Lever | Pop Safety | Steam | ASME BPVC.IV | 250 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Relief Valves for Oil

NPT Male Inlet and NPT Female Relief Port

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Set Pressure Adjustment Method | Shape | Overall Ht. | For Use With | Temp. Range, ° F | Valve Type | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—316 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 1,400 | 1 1/2 | Side | External Adjustment Screw | 90° Elbow | 8 7/8" | Oil | -320 to 420 | Relief | 15 to 75 , 50 to 150 , 100 to 300 , 200 to 600 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

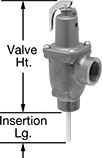

Fast-Acting Temperature- and Pressure-Relief Valves for Hot Water

NPT Male Inlet and NPT Female Relief Port

Inlet | Relief | Set Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Range, psi | Temp., ° F | Shape | Hot Water Flow Cap., BTU/hr | Insertion Lg. | Valve Ht. | Overall Ht. | For Use With | Test Mechanism | Valve Type | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Silicone Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Bottom | 150 | 1 1/2 | Side | 150 | 210 | 90° Elbow | 1,200,000 | 3" | 8 1/2" | 11 1/2" | Water | Lever | Pop Safety | ASME BPVC.IV, CSA Certified | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision-Adjustment Pressure-Relief Valves for Fuel

NPT Male Inlet and NPT Female Relief Port

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Set Pressure Adjustment Method | Shape | Overall Ht. | For Use With | Temp. Range, ° F | Valve Type | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Bronze Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 400 | 1 1/2 | Side | External Adjustment Screw | 90° Elbow | 9 1/2" | Diesel Fuel, Fuel Oil, Gasoline, Kerosene | -60 to 450 | Relief | 0 to 14 , 15 to 25 , 26 to 40 , 41 to 75 , 76 to 110 , 111 to 130 , 131 to 150 , 151 to 200 , 201 to 400 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Pressure-Relief Valves for Fuel

NPT Female Inlet and Relief Port

Inlet | Relief | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Set Pressure Adjustment Method | Shape | Overall Ht. | For Use With | Temp. Range, ° F | Valve Type | Choose a Set Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body—416 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 1,000 | 1 1/2 | Side | External Adjustment Screw | 90° Elbow | 11 1/16" | Diesel Fuel, Fuel Oil, Gasoline, Kerosene | -20 to 400 | Relief | 3 to 10 , 7 to 35 , 30 to 100 , 60 to 175 , 150 to 350 , 300 to 500 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy Duty Pressure-Regulating Valves for Water and Air

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—EPM Rubber Diaphragm and 304 Stainless Steel Seal with Internal Strainer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 300 | 1 1/2 | Side | Screw | 8 7/8" | Water, Air | 32 to 180 | 20 to 70 , 71 to 150 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Pressure-Relief Valves for Chemicals

NPT Female Inlet and Relief Port

Inlet | Relief | Set Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Port Pipe Size | Port Location | Range, psi | Adjustment Method | Shape | Features | Overall Ht. | Gauge Port Pipe Size | For Use With | Temp. Range, ° F | Valve Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dark Gray PVC Body—EPDM Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Bottom | 150 | 1 1/2 | Side | 5 to 75 | External Adjustment Screw | 90° Elbow | Gauge Port | 13 1/4" | 1/4 | Aluminum Chloride, Boric Acid | 40 to 140 | Relief | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Set Pressure-Regulating Valves for Water

Inlet | Outlet | Gauge Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Range, psi | Pressure Adjustment Method | Pipe Size | Location | Connection | End-to-End Lg. | For Use With | Temp. Range, ° F | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body—EPDM Diaphragm and Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 250 | 1 1/2 | Side | 25 to 90 | Dial | 1/4 | Side | NPT Female | 7 7/8" | Water | 33 to 140 | CSA Certified | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange-Mount Pressure-Relief Discs

Pressure-Relief Discs

Pipe Size | For Flange ANSI Class | OD | Thk. | Operating Ratio | Temp. Range, ° F | Gasket Material | Valve Type | Choose a Burst Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Graphite Body—Resin-Filled Graphite Disc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 150 | 3 1/4" | 1 1/8" | 80% | -20 to 300 | Neoprene | Rupture Disc | 20 , 25 , 30 , 40 , 50 , 60 , 75 , 100 , 125 , 150 , 175 , 200 , 250 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vacuum Rated Pressure-Relief Discs

Pipe Size | For Flange ANSI Class | OD | Thk. | Max. Vacuum, in. Hg | Operating Ratio | Temp. Range, ° F | Gasket Material | Valve Type | Choose a Burst Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Graphite Body—Resin-Filled Graphite Disc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 150 | 3 1/4" | 1 1/8" | 29.92 | 80% | -20 to 300 | Neoprene | Rupture Disc | 10 , 15 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vibration-Damping Pressure-Regulating Valves for Water, Oil, Air, and Inert Gas

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron Body—Buna-N Diaphragm and Seal with Internal Strainer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 200 | 1 1/2 | Side | Screw | 6 3/4" | Water, Oil, Air, Inert Gas | 32 to 180 | 2 to 15 , 10 to 30 , 20 to 50 , 45 to 100 , 90 to 125 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Life Pressure-Regulating Valves for Water, Oil, Air, and Inert Gas

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Buna-N Diaphragm and Seal with Internal Strainer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 400 | 1 1/2 | Side | Screw | 6 3/4" | Water, Oil, Air, Inert Gas | 32 to 180 | 2 to 15 , 10 to 30 , 20 to 50 , 45 to 100 , 90 to 150 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Regulating Valves for Chemicals

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Range, psi | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Body—Fluoroelastomer Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 125 | 1 1/2 | Side | 10 to 80 | Screw | 6 1/8" | Chemicals | 40 to 140 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Pressure-Regulating Valves for Water, Oil, Air, and Inert Gas

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Specs. Met | Choose an Outlet Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Body—316 Stainless Steel Diaphragm and 303 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 300 | 1 1/2 | Side | Screw | 4 13/16" | Water, Oil, Air, Inert Gas | 32 to 550 | ANSI/FCI 70-2 Class IV | 5 to 20 , 10 to 30 , 20 to 45 , 30 to 95 , 60 to 160 | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hydraulic Pressure-Relief Valves

Inlet Connection | Relief Connection | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Dash Size | Pipe Size | Dash Size | Lg. | Wd. | Ht. | Temp. Range, ° F | Choose a Set Pressure, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female Inlet and NPT Female Relief Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 24 | 1 1/2 | 24 | 4 1/8" | 2 7/8" | 11 1/16" | -20 to 400 | 3 to 10 , 7 to 35 , 30 to 100 , 60 to 175 , 150 to 350 , 300 to 500 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Accuracy Pressure-Regulating Valves for Steam

Valves | Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | For Use With | Temp. Range, ° F | Specs. Met | Choose an Outlet Pressure, psi | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron Body—301 Stainless Steel Diaphragm and 420 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 250 | 1 1/2 | Side | Screw | Steam | 40 to 450 | ANSI/FCI 70-2 Class IV | 3 to 20 , 5 to 50 , 10 to 100 , 20 to 150 | 0000000 | 000000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Regulating Valves for Drinking Water

Inlet | Outlet | Gauge Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Range, psi | Pressure Adjustment Method | Pressure Gauge Included | Pipe Size | Location | Connection | End-to-End Lg. | For Use With | Temp. Range, ° F | Certification | Food Industry Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Buna-N Diaphragm and Seal with Internal Strainer and Union Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 300 | 1 1/2 | Side | 25 to 75 | Screw | No | 1/4 | Bottom | NPT Female | 6 5/16" | Drinking Water | 33 to 140 | ASSE 1003 Listed, CSA Certified, IAPMO Listed | NSF/ANSI 61 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pressure-Regulating Valves for Steam

Valves | Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron Body—Bronze Diaphragm and 420 Stainless Steel Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 250 | 1 1/2 | Side | Screw | 6 1/2" | Steam | -20 to 400 | 0 to 10 , 10 to 30 , 30 to 50 , 40 to 85 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron Body—Bronze Diaphragm and PTFE Seal with Internal Strainer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 150 | 1 1/2 | Side | Screw | 6 3/4" | Steam | -20 to 400 | 2 to 15 , 10 to 30 , 20 to 50 , 45 to 100 , 90 to 150 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended-Life Vacuum-Regulating Valves for Air and Inert Gas

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Pipe Size | Location | Vacuum Range, in. Hg | Vacuum Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Neoprene Diaphragm and Chrome-Plated Bronze Seal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 1 1/2 | Side | 8 to 30 | Screw | 5 3/4" | Air, Inert Gas | -20 to 180 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Life Pressure-Regulating Valves for Steam

Inlet | Outlet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Adjustment Method | End-to-End Lg. | For Use With | Temp. Range, ° F | Choose an Outlet Pressure, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze Body—Bronze Diaphragm and PTFE Seal with Internal Strainer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | Side | 250 | 1 1/2 | Side | Screw | 6 3/4" | Steam | -20 to 400 | 2 to 15 , 10 to 30 , 20 to 50 , 45 to 100 , 90 to 150 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||