Filter by

System of Measurement

Pressure Set Point

For Use With

Thread Type

Maximum Continuous Pressure

Set Point Adjustability

Connection Material

Measurement Unit

Switch Starting Position

Housing Material

Environment

Fitting Connection

Maximum Short-Term Pressure

Maximum Switching Current @ Voltage

Approximate Difference Between Set Point and Reset Point

Operation Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Compact Pressure Switches

Wire Lead Connection

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 Threaded NPT Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 to 5,000 | 415 | 10,000 | 15,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked, CSA Certified, UL Listed | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/16"-20 Threaded UN/UNF (SAE Straight) Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 to 1,000 | 90 | 5,000 | 8,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 to 2,000 | 165 | 5,000 | 8,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIN C Connection

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 Threaded NPT Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

External Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 to 30 | 3 | 800 | 1,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 to 60 | 6 | 800 | 1,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 to 100 | 9 | 800 | 1,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 to 200 | 16 | 800 | 1,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 to 500 | 60 | 5,000 | 8,000 | ±2% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 to 1,000 | 85 | 5,000 | 8,000 | ±2% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 to 2,000 | 165 | 5,000 | 8,000 | ±2% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 to 5,000 | 415 | 10,000 | 15,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 750 to 7,500 | 605 | 10,000 | 15,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,500 to 15,000 | 1,650 | 15,000 | 20,000 | ±5% | 3 amp @ 125V AC 2 amp @ 30V DC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/16"-20 Threaded UN/UNF (SAE Straight) Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 to 1,000 | 90 | 5,000 | 8,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 to 2,000 | 165 | 5,000 | 8,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Oil, Water | IP67, NEMA 6 | CE Marked | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dual-Setpoint Electronic Pressure Switches with Digital Display

Configurable Digital Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point | Max. Continuous Pressure, psi | Signal Output | Communication Protocol | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | Measurement Unit | For Use With | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Micro M12 Connection with 4 Poles | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 14 | Adjustable | 145 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Inches of Mercury, Kilopascals, Millibars, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 36 | Adjustable | 290 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Bar, Kilopascals, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 360 | Adjustable | 1,015 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Bar, Kilopascals, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 1,450 | Adjustable | 1,810 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Bar, Kilopascals, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 3,600 | Adjustable | 7,250 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Bar, Kilopascals, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5,800 | Adjustable | 11,580 | PNP, NPN | IO Link | ±0.2% | 35 mA @ 30V DC | -10 to 175 | 316L Stainless Steel | Bar, Kilopascals, Pounds per Square Inch | Air, Argon, Diesel Fuel, Hydraulic Fluid, Inert Gas, Nitrogen, Oil, Water | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electronic Pressure Switches

1 Circuit Controlled—1 Off (Normally Open)

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Signal Output | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Micro M12 Connection with 4 Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.5 to 145 | 2.9 | 360 | 360 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 to 363 | 7.2 | 870 | 870 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 44 to 1,450 | 29 | 2,900 | 2,900 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 109 to 3,625 | 72 | 5,800 | 5,800 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 to 5,800 | 116 | 8,700 | 8,700 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Circuits Controlled—1 Off (Normally Open) and 1 On (Normally Closed)

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Signal Output | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Micro M12 Connection with 4 Pins | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 NPT Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.5 to 145 | Adjustable | 360 | 360 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 to 1,450 | Adjustable | 2,900 | 2,900 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 290 to 5,800 | Adjustable | 8,700 | 8,700 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4 BSPP Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.5 to 145 | Adjustable | 360 | 360 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 to 363 | Adjustable | 870 | 870 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 to 1,450 | Adjustable | 2,900 | 2,900 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 181 to 3,625 | Adjustable | 5,800 | 5,800 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 290 to 5,800 | Adjustable | 8,700 | 8,700 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Pressure Switches

Wire Lead Connection

Style | Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Hazardous Location Rating | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 Threaded NPT Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Internal Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 8 to 60 | 5 | 60 | 1,000 | ±5% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 10 to 100 | 9 | 100 | 1,000 | ±5% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 20 to 200 | 16 | 200 | 1,000 | ±2% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 50 to 500 | 60 | 500 | 5,000 | ±2% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 to 1,000 | 87 | 1,000 | 5,000 | ±2% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 200 to 2,000 | 165 | 2,000 | 5,000 | ±2% | 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 190 | 316 Stainless Steel | Air, Diesel Fuel, Gasoline, Hydraulic Fluid, Natural Gas, Water | IP67, NEMA 4X, NEMA 7, NEMA 9 | NEC Class I Divisions 1, 2 Groups A, B, C, D NEC Class II Divisions 1, 2 Groups E, F, G | CE Marked, CSA Certified, UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dual-Setpoint Electronic Pressure Switches

Micro M12 Connection with 4 Poles

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Signal Output | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4 Threaded BSPP Male Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

External Adjustment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2 to 145 | 2.9 | 360 | 360 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | C-UL Listed, CE Marked, UL Listed | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 to 1,450 | 29 | 2,900 | 2,900 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | C-UL Listed, CE Marked, UL Listed | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 109 to 3,625 | 72 | 5,800 | 5,800 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | C-UL Listed, CE Marked, UL Listed | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 174 to 5,800 | 116 | 8,700 | 8,700 | PNP | ±2.5% | 500 mA @ 32V DC | -10 to 175 | 316 Stainless Steel | Air, Diesel Fuel, Hydraulic Fluid, Oil, Water | IP67 | C-UL Listed, CE Marked, UL Listed | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

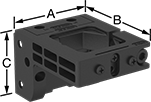

Differential Pressure Transmitters with Electronic Switch Outputs

|

Configurable Analog Transmitter Output | Configurable Digital Switch Output | Mounting Holes | Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure Differential, psi | Max. Input Pressure, psi | Input Voltage, V DC | Pipe Size | Ht. | Wd. | No. of | Signal | No. of | Signal Type | Mounting Hardware Included | Dia. | No. of | Enclosure Rating | For Use With | Accuracy | Pipe | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5 Poles Micro M12 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass-Filled Polyester Plastic Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 15 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 100 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 500 | 2,500 | 15 to 32 | 1/4 | 4 13/16" | 3" | 1 | 0 to 10V DC, 4 to 20 mA | 2 | PNP, NPN | No | 3/16" | 2 | IP65, IP67, NEMA 4X, NEMA 6 | Air, Hydraulic Fluid, Water | ±0.5% | NPT Female | 316L Stainless Steel | 14 to 158 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Pressure and Vacuum Switches

Setpoint | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pressure, psi | Vacuum, in. Hg | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | For Use With | Enclosure Rating | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/2" OD Quick Clamp Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 15 | 0 to 30 | 3 | 15 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | IP67, NEMA 6 | UL Listed | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2" OD Quick Clamp Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 15 | 0 to 30 | 3 | 15 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | IP67, NEMA 6 | UL Listed | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Pressure Switches

Pressure Set Point Range, psi | Approx. Difference Between Set Point and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current @ Voltage | Process Temp. Range, ° F | Connection Material | Wd. | For Use With | Enclosure Rating | Food Industry Std. | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wire Lead Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 1/2" OD Quick Clamp Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 to 30 | 3 | 30 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 to 60 | 5 | 60 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 to 100 | 4 | 100 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 to 200 | 16 | 200 | 1,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 2" OD Quick Clamp Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 to 30 | 3 | 30 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2 1/2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 to 60 | 6 | 60 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2 1/2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 to 100 | 4 | 100 | 1,000 | ±2% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2 1/2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 to 200 | 16 | 200 | 1,000 | ±5% | 3 amp @ 28V DC 5 amp @ 125V AC 5 amp @ 250V AC | -40 to 212 | 316 Stainless Steel | 2 1/2" | Beverage, Food | IP67, NEMA 6 | 3-A Certified 74-07 | UL Listed | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electronic Flow Switches

Pipe Connections | Flow Set Point, gpm | Max. Pressure @ Temp. | Temp. Range, ° F | Voltage, V DC | Max. Switching Current @ Voltage | End-to-End Lg. | Enclosure Rating | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum/Brass/Plastic Body with Threaded Nickel-Plated Brass Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 PNP Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 NPT Female | 0.26 to 6.6 | 360 psi @ 70° F | 32 to 185 | 30 | 100 mA @ 30V DC | 3" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 NPT Female | 1.32 to 26.4 | 360 psi @ 70° F | 32 to 185 | 30 | 100 mA @ 30V DC | 3 5/8" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electronic Insertion-Mount Flow Switches

Flow Set Point | 1 13/16" Probe Length | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Pipe Size | For Liquids, gpm | For Gas, scfm | Max. Pressure @ Temp. | Temp. Range, ° F | Voltage, V DC | Max. Switching Current @ Voltage | Body Ht. | Enclosure Rating | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Body with 316 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Digital NPN Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 1/2 3/4 1 | 0.02 to 1.5 0.05 to 4.9 0.13 to 12.7 0.23 to 23 | 0.14 to 2 0.54 to 8.05 1.21 to 18.11 2.15 to 32.21 | 4,300 psi @ 70° F | -10 to 175 | 36 | 250 mA @ 19V DC 250 mA @ 36V DC | 2 11/16" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Digital PNP Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 1/2 3/4 1 | 0.02 to 1.5 0.05 to 4.9 0.13 to 12.7 0.23 to 23 | 0.14 to 2 0.54 to 8.05 1.21 to 18.11 2.15 to 32.21 | 4,300 psi @ 70° F | -10 to 175 | 36 | 250 mA @ 36V DC 250 mA @ 18V DC | 2 11/16" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Digital NPN Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 1/2 3/4 1 | 0.02 to 1.5 0.05 to 4.9 0.13 to 12.7 0.23 to 23 | 0.14 to 2 0.54 to 8.05 1.21 to 18.11 2.15 to 32.21 | 4,300 psi @ 70° F | -10 to 175 | 36 | 250 mA @ 19V DC 250 mA @ 36V DC | 2 11/16" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Digital PNP Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 1/2 3/4 1 | 0.02 to 1.5 0.05 to 4.9 0.13 to 12.7 0.23 to 23 | 0.14 to 2 0.54 to 8.05 1.21 to 18.11 2.15 to 32.21 | 4,300 psi @ 70° F | -10 to 175 | 36 | 250 mA @ 36V DC 250 mA @ 18V DC | 2 11/16" | IP65, IP67 | C-UL Listed UL Listed CE Marked | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Electronic Insertion-Mount Flow Switches

Flow Set Point | 13/16" Probe Length | 1 13/16" Probe Length | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | For Liquids, gpm | For Gas, scfm | Max. Pressure @ Temp. | Temp. Range, ° F | Voltage, V DC | Max. Switching Current @ Voltage | Body Ht. | Enclosure Rating | Certification | Food Industry Std. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Body with 316 Stainless Steel Fittings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Digital PNP Signal Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" 2" | 0.55 to 54.21 0.97 to 96.37 | 4.84 to 72.47 8.59 to 128.84 | 430 psi @ 70° F | -10 to 200 | 36 | 250 mA @ 19V DC 250 mA @ 36V DC | 3 5/16" | IP67, IP69K | C-UL Listed UL Listed CE Marked | 3-A Certified 74-07, FDA Compliant 21 CFR 177.2415 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||