Filter by

End Diameter

Mounting Thread Size

Stylus End Shape

End Material

Stem Diameter

Precision Ball Grade

Manufacturer Model Number

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Mounting Thread Gender

Mounting Thread Pitch

Body Material

Manufacturer

Stem Material

Probe Styli

Our most general purpose probe styli, these Renishaw styli are used with both touch-trigger and scanning probes. When these styli touch your workpiece, they trigger your probe to send a signal and measure geometric features. The ball end is made of ruby, which is second only to diamond in hardness, so it won’t lose its shape or wear over time. It’s completely round and smooth to avoid touching your workpiece at more than one precise point, preventing inaccurate measurements. However, these probe styli don’t work well with aluminum or cast iron surfaces. Aluminum can rub off onto the ruby, and cast iron and ruby are prone to scratching each other during scanning jobs.

As a rule of thumb, you should choose a stylus with the shortest length and largest ball-end diameter that works for your application. If a stylus is too long, it’s more likely to move farther than it should, reducing measurement accuracy. Larger ball ends reduce the possibility that the stem will accidentally touch your workpiece and interfere with the reading.

Ruby Ball-End Styli

|

M2 Mounting Thread—Styli with M2 or M3 threads are often used in coordinate measuring machines (CMMs).

Tungsten Carbide Stem—Tungsten carbide stems are the stiffest and least likely to flex. Tungsten carbide can slightly expand in changing temperatures, so if you need precise measurements, use these styli in temperature-controlled environments.

Material | Ball | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

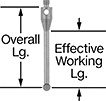

End Dia., mm | Effective Working Lg., mm | Overall Lg., mm | Stem Dia., mm | Stem | Body | End Dia. Tolerance, mm | Precision Grade | Sphericity Tolerance, mm | Mfr. | Mfr. Model No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3 | 2 | 10 | 0.2 | Tungsten Carbide | Stainless Steel | -0.00025 to 0.00025 | 10 | -0.00025 to 0.00025 | Renishaw | A-5000-7800 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EachDelivers tomorrow 7-9 am | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||