About Sump, Water-Removal, Condensate, and Submersible Pumps

More

How to Prime Your Pump

More

How to Determine Feet of Head

More

About Process Pumps

More

About Drum Pumps

More

Low-Maintenance Plastic Circulation Pumps for Water and Coolants

Eliminate seal wear and leakage with pumps that use magnets to turn the impeller. They’re often used with electroplating and photographic solutions. Pumps are gravity fed and require an elevated liquid source to fully fill the pump before turning on. Do not run dry or use with solids.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Flow Rate, gpm | Intake | Discharge | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 10 ft. of Head | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | hp | Current, A | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Thread Type | Lg. | Wd. | Ht. | Each | |

120V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

Plug | ||||||||||||||||||

| 8 | 5 | 14.6 | 6 | 20 | 35° to 150° | 1/30 | 1.5 | 1/2 | Female | NPT | 1/2 | Male | NPT | 8 1/2" | 4" | 4 3/8" | 0000000 | 0000000 |

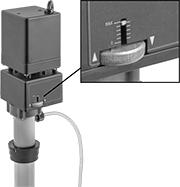

Precise-Flow Electric Drum Pumps for Water, Oil, and Chemicals

For accurate dispensing in extremely low-flow applications, adjust flow in 2% increments. These pumps are compatible with chemicals such as ammonia and etching and cleaning solutions.

Temp. Range, °F | Intake | Discharge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Horsepower | Current, A | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Each | |

120V AC, Single Phase | ||||||||||||||||

Plug | ||||||||||||||||

| 0.001-0.01 | 100 | 30 | 1,500 | 35° | 125° | 1/30 hp | 1.7 | 2" | Tube Nut Connector | 3/8" | 20ft. | 1/4" | 1/4" | 20ft. | 0000000 | 0000000 |

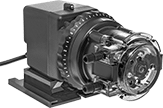

High-Pressure Metering Pumps for Chemicals

These pumps can be used with pressures four times higher than standard pumps. An adjustment dial lets you alter flow rate in 2.5% increments of the maximum flow without the hassle of changing tubing. Often used in boiler feed systems and water treatment, they're compatible with chemicals such as cleaning fluids and acid-washing solutions. Pumps are self-priming and create suction to draw liquid upward. They can run dry.

Pumps | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Discharge | Overall | Replacement Pump Heads | Replacement Tubing | ||||||||||||||

| Flow Rate, gal./day | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Horsepower | Current, A | Tube ID | Tube OD | Lg. | Wd. | Ht. | Includes | Each | Each | Each | |||

120V AC, Single Phase | |||||||||||||||||

Plug | |||||||||||||||||

| 0.3-5 | 100 | 1,500 | 35° to 125° | 1/30 hp | 1.7 | 3/16" | 1/4" | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 |

| 0.8-17 | 100 | 1,500 | 35° to 125° | 1/30 hp | 1.7 | 3/16" | 1/4" | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 |

| 2-40 | 100 | 1,500 | 35° to 125° | 1/30 hp | 1.7 | 3/16" | 1/4" | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 |

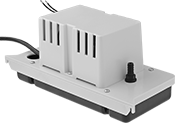

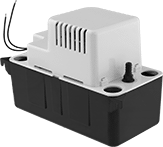

Condensate Pumps with Tank

Equipped with a built-in container for condensate, these pumps work alongside your system to remove condensate from air conditioners, refrigerators, dehumidifiers, and other equipment. They are not submersible. A safety switch turns off your equipment in case of pump failure. Pumps turn on and off automatically.

Style B pumps have a low profile for use in areas with limited clearance.

Style C pumps are often used with medium tonnage air conditioning and refrigerating units.

Max. Flow Rate, gpm | Level | Discharge | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Electrical Connection Type | Tank Capacity, gal. | @ 1 Ft. of Head | @ 5 Ft. of Head | @ 10 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn On | Turn Off | Temp. Range, °F | Horsepower | Current, A | Tube Connection Type | For Tube ID | Ht. | Wd. | Dp. | Each | |

120V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

| B | Plug | 0.3 | 1.3 | 1.1 | 0.8 | 20 | 9 | 1" | 1/2" | 35° to 120° | 1/30 hp | 1.5 | Barbed | 3/8" | 5" | 5" | 12" | 00000000 | 0000000 |

240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

| B | Plug | 0.3 | 1.3 | 1.1 | 0.8 | 14 | 7 | 1" | 1/2" | 35° to 120° | 1/30 hp | 0.5 | Barbed | 3/8" | 5" | 5" | 12" | 00000000 | 000000 |

Max. Flow Rate, gpm | Level | Discharge | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Electrical Connection Type | Tank Capacity, gal. | @ 1 Ft. of Head | @ 5 Ft. of Head | @ 10 Ft. of Head | Max. Ft. of Head, ft. | Max. Pressure, psi | Turn On | Turn Off | Temp. Range, °F | Horsepower | Current, A | Tube Connection Type | For Tube ID | Ht. | Wd. | Dp. | Each | |

120V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

| C | Plug | 0.5 | 1.3 | 1.1 | 0.8 | 20 | 9 | 2 1/4" | 1 1/4" | 35° to 120° | 1/30 hp | 1.5 | Barbed | 3/8" | 7" | 5" | 11" | 00000000 | 0000000 |

240V AC, Single Phase—With Thermal Overload Protection | |||||||||||||||||||

| C | Plug | 0.5 | 1.3 | 1.1 | 0.8 | 17 | 7 | 2 1/4" | 1 1/4" | 35° to 120° | 1/30 hp | 0.5 | Barbed | 3/8" | 7" | 5" | 11" | 00000000 | 000000 |