How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

High-Purity PVDF Pipe Fittings for Corrosive Chemicals

Made of PVDF that’s finished to a 12 Ra smoothness, these fittings handle some of the harshest chemicals without leaching contaminants into your line. They won’t accumulate particles and are easy to clean, thanks to their smoothness. Comparable to Kynar, these fittings handle most organic solvents that would dissolve CPVC, and chlorine or nitric acid that would weaken polypropylene. You can use them at higher temperatures than CPVC and polypropylene. These fittings meet UL 94 V-0 and FM standards for flame retardance. They’re also FDA compliant for direct contact with food, and they meet ASTM requirements for dimensions and tolerances.

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3261, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Pipe Nipples and Pipe: Use SDR 21 PVDF Plastic

- Flanges: Use PVDF Plastic

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

| 1/2 | 37/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

| 3/4 | 5/8" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 | 45/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 59/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 00000 |

| 2 | 1 5/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3222, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Seal Material: Viton® Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | White | 230 psi @ 72° F | 0000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | White | 230 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | White | 230 psi @ 72° F | 0000000 | 00000000 |

| Each | ||

| 00000000 | 0000000 |

Flame-Retardant PVDF Pipe Flanges for Chemicals

- For Use With: Chlorine, Salt Water, Solvents

- Temperature Range: 40° to 280° F

- Specifications Met: ASTM D3222, UL 94 V-0

- Pipe Nipples and Pipe: Use Schedule 80 PVDF Plastic

- Fittings: Use Schedule 80 PVDF Plastic

Flanges meet UL 94 V-0 for flame retardance to delay the spread of flames to valuable equipment. They are made of PVDF (polyvinylidene fluoride), which is comparable to Kynar, and has the chemical resistance to stand up to solvents and other harsh substances. Also known as Pressure Class 150 flanges, they have thick, strong walls for heavy duty chemical processing applications. Bolt two same-size flanges together with a gasket (sold separately) to create an access point within a line. When connecting to pipe, apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the flange, then wrench-tighten one to two turns. Flanges meet ASTM D3222 specifications and testing requirements for material quality.

Warning: Never use plastic pipe flanges and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

| Pipe Size | Flanged Connection Surface | Flange OD | For Bolt Dia. | Bolt Hole Dia. | Number of Bolt Holes | Bolt Circle Dia. | Material | Color | Max. Pressure | Each | |

Fixed Flange, Female Threaded × Flanged | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

NPT Threads | |||||||||||

| 1/2 | Flat | 3 1/2" | 1/2" | 5/8" | 4 | 2 5/16" | PVDF Plastic | Red | 150 psi @ 72° F | 00000000 | 0000000 |

| 3/4 | Flat | 3 7/8" | 1/2" | 5/8" | 4 | 2 11/16" | PVDF Plastic | Red | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | Flat | 4 1/4" | 1/2" | 5/8" | 4 | 3 1/32" | PVDF Plastic | Red | 150 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | Flat | 5" | 1/2" | 5/8" | 4 | 3 3/4" | PVDF Plastic | Red | 150 psi @ 72° F | 00000000 | 000000 |

| 2 | Raised | 6" | 5/8" | 3/4" | 4 | 4 3/4" | PVDF Plastic | Red | 150 psi @ 72° F | 00000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Oil

- Temperature Range: See table

| Pipe Size | Drive Size | Material | Color | Max. Pressure | Minimum Temperature, °F | Maximum Temperature, °F | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/16 | 5/16" | PVDF Plastic | White | Not Rated | Not Rated | Not Rated | 0000000 | 00000 |

Chemical-Resistant PVDF Pipe Fittings for Food and Beverage

- For Use With: Beverage, Chlorine, Deionized Water, Food, Hydrochloric Acid, Phosphoric Acid

- Temperature Range: 0° to 240° F

- Specifications Met: FDA Compliant 21 CFR 177.2510, IEC 60695-11-10, NSF/ANSI 61

Made of PVDF, also known as Kynar, these fittings stand up to the harsh chemicals used to clean food processing lines. Unlike other plastic fittings, such as nylon and acetal fittings, they’ll resist degrading when exposed to strong alkali and highly acidic solutions. These fittings are FDA compliant and meet NSF/ANSI 61, so they're safe to make direct contact with food and drinking water. They also won't transfer tastes or odors to your food and beverages. Use them with both hot and cold substances. Since they're made of PVDF, these fittings can stand up to impact. They meet strict IEC standards for flame retardance, so they delay the spread of flames.

Since these fittings are threaded, you can take apart their connections for maintenance and repair. When connecting to another fitting, apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection, be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

| Pipe Size | Drive Size | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 7/16" | PVDF Plastic | White | 200 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 9/16" | PVDF Plastic | White | 200 psi @ 72° F | 0000000 | 0000 |

| 3/8 | 21/32" | PVDF Plastic | White | 200 psi @ 72° F | 0000000 | 0000 |

| 1/2 | 7/8" | PVDF Plastic | White | 200 psi @ 72° F | 0000000 | 0000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

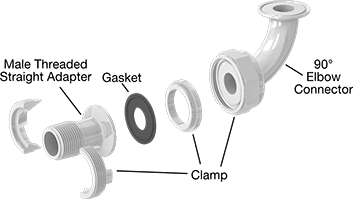

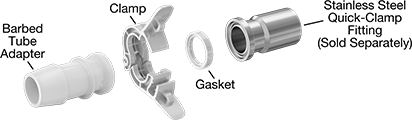

Plastic Quick-Clamp Sanitary Fittings for Stainless Steel Tubing

- For Use With: Dairy, Water

- Temperature Range: -40° to 170° F, except gaskets (see table)

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM A270

- Specifications Met: 3-A Certified 62-02, FDA Compliant 21 CFR 177.2510

Made of PVDF (Kynar), these fittings are lightweight compared to metal quick-clamp fittings. The clamp separates into three pieces and threads over the quick-clamp ends of the fittings to create an access point in a line. Tighten the clamp with a spanner wrench (sold separately) for a secure seal.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

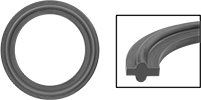

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

EPDM Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

Multiline Quick-Disconnect Tube Couplings for Air

Don’t get your lines crossed—use one of these couplings to quickly connect or disconnect multiple tubes at once. They keep tubes organized and optimize space in tight spots. Often used in robotics, these couplings are ideal for complex pneumatic systems.

Through-wall couplings allow you to connect and disconnect air lines on a panel or machine. This is useful when you are going to transport and reconnect your equipment on site.

Barbed-connect fittings are for soft tubing.

Keyed couplings prevent mixing and matching the wrong lines, since they’ll only connect with a plug or socket that is keyed the same.

For a complete coupling, order a plug and a socket with the same coupling size.

- Maximum Pressure: 100 psi @ 72° F

- Temperature Range: -40° to 180° F

- Tubing: Use with soft or firm (Durometer 45A-90A) polyurethane rubber or PVDF plastic

To connect the coupling, slide the latch to the lock position. To disconnect, slide the latch to the open position. Made of plastic, these couplings are lighter in weight than brass couplings.

To install in a panel, machinery, or bulkhead, add a through-wall adapter ring (sold separately).

Tube Couplings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Mated | Through-Wall Adapter Rings | |||||||||

| For Tube ID | No. of Connections | Material | Max. Vacuum | OD | Lg. | Features | Each | Each | ||

Plugs | ||||||||||

| 1/16" | 10 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 57/64" | 1 29/64" | Keyed Connections | 0000000 | 000000 | 0000000 | 000000 |

| 1/8" | 10 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 57/64" | 1 39/64" | Keyed Connections | 0000000 | 00000 | 0000000 | 00000 |

Sets | ||||||||||

| 1/16" | 10 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 57/64" | 1 29/64" | Keyed Connections | 0000000 | 00000 | 0000000 | 00000 |

| 1/8" | 10 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 57/64" | 1 39/64" | Keyed Connections | 0000000 | 00000 | 0000000 | 00000 |

- Maximum Pressure: 100 psi @ 72° F

- Temperature Range: -40° to 180° F

- Tubing: Use with soft or firm (Durometer 45A-90A) polyurethane rubber or PVDF plastic

Connect the coupling with a push and disconnect by pressing the latch. Made of plastic, these couplings are lighter in weight than brass couplings.

If you want the coupling to rotate freely after it’s installed to avoid kinks in your tube, choose one with a swivel.

Mated | Plugs | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | No. of Connections | Material | Max. Vacuum | OD | Lg. | For Hole Dia. | For Max. Wall Thick. | Features | Each | |

Swivel | ||||||||||

| 1/16" | 2 | Acetal Plastic | 24 in. of Hg @ 72° F | 3/4" | 2 1/64" | 11/16" | 1/2" | __ | 0000000 | 000000 |

| 1/8" | 2 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 3/64" | 2 1/2" | 11/16" | 1/2" | __ | 0000000 | 00000 |

Non-Swivel | ||||||||||

| 1/8" | 6 | Acetal Plastic | 24 in. of Hg @ 72° F | 1 21/32" | 2 7/32" | 1 13/64" | 1/8" | Keyed Connections | 0000000 | 00000 |

Plastic Push-to-Connect Tube Fittings for Chemicals

- For Use With: Inch: Alcohol, Hydrochloric Acid, Nitric Acid, Sodium Carbonate, Sulfuric Acid

Metric: Acetic Acid, Alcohol, Arsenic Acid, Benzoic Acid, Fluoboric Acid, Sodium Carbonate, Sulfuric Acid - Temperature Range: Inch: 0° to 270° F

Metric: 32° to 175° F - Tubing: Use with hard (Durometer 55D-60D) FEP plastic

Also known as instant fittings, these chemical-resistant plastic fittings connect to tubing with a push. An internal gripping ring holds the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Use these fittings in low-pressure applications.

PVDF fittings offer excellent chemical resistance, and can be used with hydrochloric acid and nitric acid. They withstand temperatures up to 270° F, higher than other push-to-connect fittings for chemicals. They are produced in a clean room and are bagged individually to prevent dirt and moisture from contaminating the inside. PVDF is also known as Kynar.

Caps fit over a tube stem end of a fitting or a piece of tubing.

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Each | |

| 1/4" | PVDF Plastic | Black | Gray | 300 psi @ 72° F | 0000000 | 00000 |

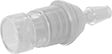

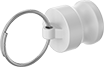

Luer Lock Tube Couplings for Plastic and Rubber Tubing—Chemicals

- For Use With: Acetic Acid, Bleach, Ethanol, Hydrochloric Acid, Nitric Acid, Phosphoric Acid, Sulfuric Acid

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

A staple in labs, these couplings are highly versatile, fitting any luer lock plug, socket, syringe, or needle. They lock together with a push and turn, so they work well in lines that are frequently disconnected. Use them in low-pressure applications. They have a compact body for installation in tight spaces. Made of PVDF, they resist most acids, alcohols, and organic solvents. PVDF is also known as Kynar.

Note: For a complete coupling, order a plug and a socket.

| Material | Color | Clarity | Max. Pressure | Pkg. Qty. | Pkg. | |

| PVDF Plastic | White | Semi-Clear | Not Rated | 10 | 0000000 | 00000 |

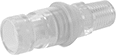

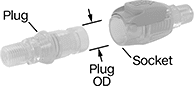

High-Flow Quick-Disconnect Tube Couplings for Chemicals

- For Use With: Acetic Acid (20%), Ammonia, Carbon Dioxide, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydraulic Fluid (Petroleum Based), Hydrochloric Acid, Hydrogen Peroxide (30%), Kerosene, Methanol, Nitric Acid (20%), Potassium Hydroxide, Sodium Carbonate, Sodium Hydroxide (20%), Sulfuric Acid (75%), Synthetic Oil

- Temperature Range: 32° to 250° F

- Tubing: Use with soft or firm (Durometer 55A-95A) nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PVC plastic or TPE plastic

A spring-free flow path allows more chemicals to pass through these tube couplings at lower line pressures than other quick-disconnect couplings. This reduces turbulence, foaming, bubbles, and blockage. They have a shut-off valve that stops the flow when the coupling is disconnected, so chemicals won’t leak from your line. Unlike couplings with a button release, these have a safety slide to reduce accidental separation from bumps or drops. They are often used in laboratories, pharmaceutical facilities, and other sterile environments.

Made of PVDF, also known as Kynar, these couplings have excellent chemical and UV resistance at ambient and elevated temperatures. They also resist abrasion, impact, flames, and corrosion. Compared to other quick-disconnect couplings for chemicals, these couplings can withstand higher temperatures—all the way up to 250° F.

When you insert the plug into the socket, it’ll connect with a click. To disconnect, slide the latch on the socket and remove the plug.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

They have a single barb that grips onto tubing or hose and provides a smooth clamping surface for extra-tight connections that minimize leaks.

Quick-Clamp Fittings for Dairy

- Temperature Range: See table

- Tubing: Use with soft (Durometer 50A-65A) silicone rubber

- Specifications Met: See table

Also known as single-use fittings, these are disposable so you don't have to sterilize your line. Join the flanged end of the fittings to any other sanitary stainless steel quick-clamp fitting (sold separately) with a gasket and a clamp for a fast and easy way to access your line. Fittings have a smooth interior to prevent product buildup and contamination. They are PVDF (also known as Kynar), which has excellent strength.

Note: For a complete connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

| For Tube OD | Flange OD | Material | Color | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 3/4" | 0.98" | PVDF Plastic | White | 80 psi @ 72° F | Not Rated | FDA Compliant 21 CFR 177.2510, USP Class VI | 0000000 | 000000 |

| For Tube OD | For Flange OD | Material | Color | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | Nylon Plastic | White | 80 psi @ 72° F | 0° to 140° | FDA Compliant 21 CFR 177.1500, USP Class VI | 0000000 | 000000 |

| For Tube OD | For Flange OD | Gasket Material | Gasket Color | Maximum Pressure | Temp. Range, °F | Each | |

| 3/4" | 0.984" | Silicone Rubber | Clear | 80 psi @ 72° F | 0° to 140° | 0000000 | 00000 |

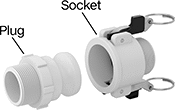

Plastic Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of plastic, these couplings are lighter in weight than metal cam-and-groove hose couplings, yet have the chemical resistance to withstand gasoline and other harsh substances. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Sockets with locking levers prevent accidental disconnection. The locking pins engage automatically when the coupling is connected. Press the locking pins simultaneously to disengage.

PVDF plugs and sockets have better corrosion and chemical resistance than nylon plugs and sockets. Use them when your application involves harsh acids and solvents.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: See table

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

Caps | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Levers | Replacement Gaskets | |||||||||

| Coupling Size | Socket ID | Color | No. of | Material | Max. Pressure | Each | Pkg. Qty. | Pkg. | ||

PVDF Plastic | ||||||||||

| 1 1/2 | 2 1/8" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 000000 | 10 | 0000000 | 000000 |

| 2 | 2 1/2" | White | 2 | 304 Stainless Steel | 100 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

| 3 | 3 5/8" | White | 2 | 304 Stainless Steel | 50 psi @ 72° F | 00000000 | 00000 | 10 | 0000000 | 00000 |

- For Use With:

Nylon Plastic: Diesel Fuel, Gasoline, Varnish

PVDF Plastic: Diesel Fuel, Gasoline, Nitric Acid, Phosphoric Acid - Maximum Pressure: 125 psi @ 72° F

- Temperature Range:

Nylon Plastic: -30° to 200° F

PVDF Plastic: -20° to 250° F - Specifications Met: Fed. Spec. A-A-59326

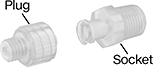

Quick-Disconnect Plastic-Shape Hose Couplings for Food and Beverage

Couplings are suitable for food and beverage applications and won’t impart tastes or odors to the product. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a line. All of the quick-disconnect food and beverage plugs are compatible with any of the quick-disconnect food and beverage sockets of the same coupling size, regardless of the pipe size. They are PVDF, which has excellent abrasion and corrosion resistance and withstands the damaging effects of UV light.

Plugs are also known as nipples.

Sockets have a shut-off valve that stops the flow when the coupling is separated, so product won’t leak from the line. They are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket back until the plug ejects.

- Maximum Pressure: 100 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: 0° to 250° F

Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Type | Color | Each | |

PVDF Plastic | |||||||

| 1/4 | 13/32" | 13/32" | 3/8 | NPT | White | 0000000 | 000000 |

- Maximum Pressure: 100 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: 0° to 250° F

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Thread Type | Color | Each | |

PVDF Plastic | |||||||

| 1/4 | 13/32" | 13/32" | 1/4 | NPT | White | 0000000 | 000000 |