Filter by

System of Measurement

Reamer Diameter

For Use On

Reamer Fractional Size

Reamer Type

Sold As

Spiral Direction

Container Type

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Length Class

For Deburring

Performance

Reamers

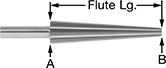

Round Shank

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Flute | Overall | No. of Flutes | Spiral Direction | Cutting Dia. Tolerance | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | High-Speed Steel | 7/8" | 3 1/2" | 4 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | Cobalt Steel | 7/8" | 3 1/2" | 4 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | Carbide | 5/8" | 2 1/4" | 4 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Fiberglass, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel, Hardened Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | High-Speed Steel | 7/8" | 3 1/2" | 4 | Right Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | High-Speed Steel | 7/8" | 3 1/2" | 4 | Left Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | Titanium Nitride (TiN)-Coated High-Speed Steel | 7/8" | 3 1/2" | 4 | Right Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Shank

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Square Shank Size | Flute | Overall | No. of Flutes | Spiral Direction | Cutting Dia. Tolerance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | High-Speed Steel | 0.095" | 1 1/2" | 3" | 4 | — | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" (1/8") | High-Speed Steel | 0.095" | 1 1/2" | 3" | 4 | Left Hand | 0" to 0.0002" | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reamer Sets

Round Shank

Sizes Included | No. of Pieces | Material | Spiral Direction | Lg. Class | Container Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/4" (Increments of 1/64") | 13 | High-Speed Steel | — | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | — | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | — | Wood Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | — | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/32") | 15 | High-Speed Steel | — | — | Roll-Up Pouch | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/64") | 29 | High-Speed Steel | Right Hand | — | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16"-1/2" (Increments of 1/32") | 15 | High-Speed Steel | Right Hand | Jobbers | Metal Case | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reamers for Deburring

Round Shank

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (B to A) | Material | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance | For Deburring | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" to 0.5000" (1/8" to 1/2") | High-Speed Steel | 3 5/8" | 5 9/16" | 6 | -0.003" to 0.003" | Sheet Edges | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

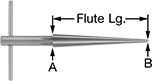

T-Handle Shank

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (B to A) | Material | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance | For Deburring | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1250" to 0.5000" (1/8" to 1/2") | High-Speed Steel | 3 5/8" | 5 9/16" | 6 | -0.003" to 0.003" | Sheet Edges | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

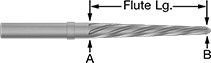

Reamers for Hole Alignment

Round Shank

Lg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. (A) | Reamer Dia. (B) | Material | Flute | Overall | Spiral Direction | Cutting Dia. Tolerance | Performance | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.1875" (3/16") | 0.1250" | High-Speed Steel | 1 3/8" | 3 1/2" | Left Hand | 0" to 0.005" | Depth Limiting | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.2188" (7/32") | 0.1250" | High-Speed Steel | 1 3/8" | 3 1/2" | Left Hand | 0" to 0.005" | Depth Limiting | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.2500" (1/4") | 0.1250" | High-Speed Steel | 1 7/8" | 4" | Left Hand | 0" to 0.005" | Depth Limiting | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round-Shank Reamer Drill Bits

Dia. | Lg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Size | Reamer | Shank | Max. Drilling Dp. | Flute | Overall | No. of Flutes | Flute Type | Cutting Dia. Tolerance | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.1250" | 1/8" | 0.75" | 0.75" | 3" | 4 | Straight | 0" to 0.0005" | Carbon Fiber, Fiberglass, Graphite | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||