Filter by

Reamer Diameter

System of Measurement

Reamer Type

Sold As

Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

Taper Pin Number

Square Shank Size

Spiral Direction

Reamers for Taper-Pin Holes

Shape holes to match the profile of taper pins. After drilling a hole that matches the size of the small end of the taper pin you want to install, use these reamers to taper and finish the hole.

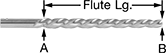

Round Shank

|

Helix Flute |

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Helix Flute—Prevent clogging when removing excess material with helix flutes. They also leave a smoother finish than straight flutes.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Left-Hand Spiral—These reamers push chips downward as they cut, so they're often used in through holes.

Lg., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Taper Pin No. | Reamer Dia. (A), mm | Reamer Dia. (B), mm | Material | Flute | Overall | No. of Flutes | Spiral Direction | Cutting Dia. Tolerance, mm | Rate of Taper | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Helix Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 mm | 3.4600 | 2.4000 | High-Speed Steel | 53 | 79 | 3 | Left Hand | -0.0254 to 0.0254 | 1:48 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 30025A62 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

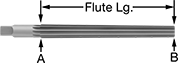

Square Shank

|

Straight Flute |

Turn these reamers by hand with an adjustable wrench, straight-handle tap wrench, or pin vise (sold separately).

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Lg., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Taper Pin No. | Reamer Dia. (A), mm | Reamer Dia. (B), mm | Material | Square Shank Size, mm | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance, mm | Rate of Taper | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 mm | 3.3600 | 2.4000 | High-Speed Steel | 2.8 | 48 | 68 | 4 | 0 to 0.075 | 1:50 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 30165A62 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reamers

Finish holes to precise inch, metric, wire gauge, or letter sizes with these reamers.

Round Shank

Straight Flute |

These reamers fit in the chuck of drill presses, turret lathes, and other machine and power tools, making them the most common shank type.

Straight Flute—The most common flute style, these reamers are suitable for a wide range of applications, but not recommended for holes with a keyway or other breaks in the surface.

High-Speed Steel—Durable and wear resistant, these are good for general purpose reaming in most materials.

Lg., mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reamer Dia. | Material | Flute | Overall | No. of Flutes | Cutting Dia. Tolerance, mm | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flute | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4000 mm | High-Speed Steel | 19.1 | 76.2 | 4 | 0 to 0.005 | Aluminum, Brass, Bronze, Iron, Plastic, Stainless Steel, Steel | 8851A132 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||