How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

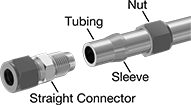

Precision Compression Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. Also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are 316 stainless steel for excellent corrosion resistance. A molybdenum disulfide coating on the nut acts as a lubricant for easy installation.

For Tube (A) | For Tube (B) | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Max. Pressure | Each | |

| 3/16" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 3,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/8" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4" | 0.035" | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8" | 0.035" | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.049" | 1/2" | 0.049" | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 | 00000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | |

| 1/8" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 |

| 3/16" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 |

| 1/4" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 |

| 5/16" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 3,200 psi @ 72° F | 00000000 |

| 3/8" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 |

| 1/2" | 0.035" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 |

| 3/4" | 0.049" | Molybdenum-Disulfide-Coated 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 |

For Tube | ||||

|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | 00000000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | 00000000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,200 psi @ 72° F | 00000000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,600 psi @ 72° F | 00000000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,100 psi @ 72° F | 00000000 |

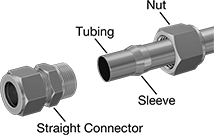

Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Made to tighter tolerances than other compression fittings, these are designed for high-precision applications. They are also known as instrumentation fittings and flareless fittings. They come with a nut and a single sleeve (ferrule). The sleeve bites into tubing as you tighten the nut to create a strong seal. Fittings are brass for good corrosion resistance.

Fittings with a molybdenum-disulfide brass nut are easy to install because the coating acts as a lubricant.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Material | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/16" | 0.014" | 1/16 | Brass | Brass | 2,600 psi @ 72° F | 0000000 | 000000 |

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 1/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 3/16" | 0.035" | 1/8 | Brass | Brass | 2,300 psi @ 72° F | 0000000 | 0000 |

| 1/4" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/8 | Brass | Brass | 1,200 psi @ 72° F | 0000000 | 0000 |

| 5/16" | 0.035" | 1/4 | Brass | Brass | 1,200 psi @ 72° F | 0000000 | 0000 |

| 3/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.065" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Material | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/16" | 0.02" | 1/16 | Brass | Molybdenum-Disulfide-Coated Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 1/8" | 0.035" | 1/4 | Brass | Brass | 3,600 psi @ 72° F | 0000000 | 00000 |

| 3/16" | 0.035" | 1/8 | Brass | Brass | 2,300 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 0000 |

| 1/4" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.065" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Nut Material | Max. Pressure | Each | |

| 1/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 000000 |

| 3/16" | 0.035" | Brass | Brass | 2,300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 0.035" | Brass | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Nut Material | Max. Pressure | For Hole Dia. | For Max. Wall Thick. | Each | |

| 1/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 5/16" | 1/2" | 00000000 | 000000 |

| 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 7/16" | 17/32" | 00000000 | 00000 |

| 5/16" | 0.035" | Brass | Brass | 1,200 psi @ 72° F | 1/2" | 7/16" | 00000000 | 00000 |

| 3/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 9/16" | 9/16" | 00000000 | 00000 |

| 1/2" | 0.049" | Brass | Brass | 1,100 psi @ 72° F | 3/4" | 1/2" | 00000000 | 00000 |

| 5/8" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 7/8" | 19/32" | 00000000 | 00000 |

For Tube (A) | For Tube (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | OD | Wall Thick. | Material | Nut Material | Max. Pressure | Each | |

| 1/4" | 0.035" | 1/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 000000 |

| 5/16" | 0.035" | 1/4" | 0.035" | Brass | Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | 1/4" | 0.049" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | 3/8" | 0.049" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Material | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 000000 |

| 1/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 3/16" | 0.035" | 1/8 | Brass | Brass | 2,300 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 3/8 | Brass | Brass | 1,600 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/8 | Brass | Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/4 | Brass | Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.065" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | Molybdenum-Disulfide-Coated Brass | 3,800 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

Inline tees are also known as branch tees.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Material | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/8" | 0.028" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 000000 |

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.028" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.028" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | Brass | 1,600 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.065" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 000000 |

Inline tees are also known as branch tees.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Material | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/8" | 0.028" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 000000 |

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 3/16" | 0.028" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 0.028" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.028" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.065" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

Right-angle tees are also known as run tees.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Nut Finish | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/8" | 0.028" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 000000 |

| 1/8" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 0000000 | 00000 |

| 3/16" | 0.028" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.028" | 3/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.028" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | 1/2 | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 0000000 | 00000 |

| 3/4" | 0.065" | 3/4 | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 0000000 | 000000 |

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Nut Material | Max. Pressure | Each | |

| 1/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 000000 |

| 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.065" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Nut Material | Max. Pressure | Each | |

Caps For Tubing | ||||||

| 1/8" | 0.035" | Brass | Brass | 3,600 psi @ 72° F | 00000000 | 00000 |

| 3/16" | 0.035" | Brass | Brass | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.049" | Brass | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.065" | Brass | Brass | 1,200 psi @ 72° F | 00000000 | 00000 |

Caps For Fitting | ||||||

| 3/16" | 0.035" | Brass | __ | 1,200 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Brass | __ | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | __ | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | __ | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.049" | Brass | __ | 1,200 psi @ 72° F | 00000000 | 0000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Molybdenum-Disulfide-Coated Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.049" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 0.065" | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 0.065" | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | Brass | 2,700 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.049" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 0.065" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 0.065" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

Sleeves for Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Use these sleeves with precision compression nuts and fittings to create a strong seal on copper tubing. Made to tighter tolerances than other sleeves, they are designed for high-precision applications. Sleeves are brass for good corrosion resistance. They are also known as ferrules.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | Brass | 2,700 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.049" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 0.065" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 0.065" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

Nuts for Precision Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -40° to 350° F

- Tubing: Use with seamless copper that meets ASTM B68, ASTM B75, or ASTM B88

- Compatible With: Parker CPI

Use these nuts with precision compression sleeves and fittings to create a strong seal on copper tubing. Made to tighter tolerances than other nuts, they are designed for high-precision applications. They are brass for good corrosion resistance.

Nuts that have a molybdenum-disulfide finish are easy to install because the finish acts as a lubricant.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1/16" | 0.02" | Molybdenum-Disulfide-Coated Brass | 3,800 psi @ 72° F | 00000000 | 00000 |

| 1/8" | 0.035" | Molybdenum-Disulfide-Coated Brass | 2,700 psi @ 72° F | 00000000 | 0000 |

| 3/16" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.049" | Molybdenum-Disulfide-Coated Brass | 1,200 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 0.065" | Molybdenum-Disulfide-Coated Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 0.065" | Molybdenum-Disulfide-Coated Brass | 1,000 psi @ 72° F | 00000000 | 0000 |