How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

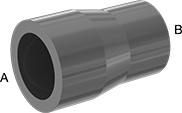

Fiberglass Pipe Fittings for Corrosive Chemicals

- For Use With: Acetic Acid (75%), Alcohol, Calcium Chloride, Chlorine, Fuel Oil, Gasoline, Hydrochloric Acid (37%), Nitric Acid (10%), Oil, Phosphoric Acid, Salt Water (30%), Sodium Hydroxide (50%), Solvents, Sulfuric Acid (70%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D3567

These fittings have excellent corrosion resistance to handle a wide range of acids and other highly-corrosive chemicals. They are commonly used in metal surface treating applications, plating solution lines, and other chemical process applications. Reinforced with layers of fiberglass, they have better strength and durability than any of our other pipe fittings for chemicals. Fittings meet ASTM D3567 specifications for product dimensions.

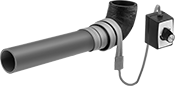

To connect fittings to pipe, first sand the inside of the fitting and the end of the pipe to remove the surface finish. Next, mix the adhesive (sold separately) until the color is uniform with no streaks. Apply a thin layer of mixed adhesive to the sanded area of the pipe, approximately 1/8” thick. Repeat this process with the inside of the fitting, applying a layer approximately 1/16” thick. After sealant has been applied, push the fitting onto the pipe until it is fully engaged. Finally, use the adhesive-curing heat cable (sold separately) to cure the adhesive. Wrap the tape around the pipe and fitting at the joint, taking care to not overlap the tape. Once you have waited the full cure time, the pipe and fitting will be ready to use.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

(A) | (B) | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Dp. | Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

| 2 | 1 1/2" | 1 1/2 | 1 5/16" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 0000000 |

| 3 | 2" | 1 1/2 | 1 1/2" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 3 | 2" | 2 | 1 1/2" | Fiberglass | Black | 250 psi @ 72° F | 0000000 | 000000 |

| 4 | 2 5/8" | 2 | 1 1/2" | Fiberglass | Black | 150 psi @ 72° F | 0000000 | 000000 |

| 4 | 2 5/8" | 3 | 2" | Fiberglass | Black | 150 psi @ 72° F | 0000000 | 000000 |

| Pipe Cement (11.8-fl. oz. Can) | 0000000 | Each | 000000 |

| Voltage | Max. Heat Output, °F | Lg. | Wd. | Thick. | Plug Type | Cord Lg. | Each | |

| 120V AC | 270° | 6 ft. | 1" | 1/8" | Two Prong | 6 ft. | 0000000 | 0000000 |

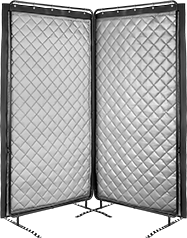

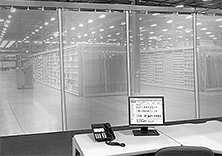

Sound Barrier Partitions

Set up these free-standing partitions to reflect sound and block noise from traveling to other parts of your facility. A vinyl barrier is sandwiched between two vinyl-coated fiberglass absorbers. Partitions have five grommets across the top for attaching to the frame; hook-and-loop fasteners on the sides join multiple partitions together.

| Sound Blocked | Thick. | Wd. | Lg., ft. | Material | Temp. Range, °F | Features | Each | |

| 25 dBA to 27 dBA | 2" | 54" | 8 1/2 | Vinyl-Coated Fiberglass | -20° to 180° | Five 5/8" Grommets on Top Edge, Frame, Hook and Loop Fasteners on Sides, Moisture Barrier | 00000000 | 0000000 |

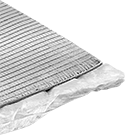

Sound Barrier Sheets

Reflect sound and block noise from traveling to other parts of your facility.

Plain-back melamine foam and fiberglass sheets have an additional layer to reduce noise within an area. They can be used to line machinery enclosures.

Facing | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sound Transmission Loss (STL), dB | Thick. | Wd. | Color | Texture | Material | Temp. Range, °F | Features | Specifications Met | Lengths, ft. | Per Ft. | |

Plain-Black Fiberglass | |||||||||||

| 29 | 1" | 54" | Yellow | Wrinkled | Aluminum Foil | -20° to 180° | Moisture Barrier | ASTM E84 15/20 For Flame and Smoke | 0000000 | 000000 | |

| Tape for Wrinkled Aluminum Foil Facing Sheets | 000000 | Each | 0000000 |

Easy-to-Hang Sound Barrier Sheets

Suspend these thin sheets to reflect sound and block noise from traveling to other parts of your facility.

Vinyl-coated fiberglass sheets have a vinyl moisture barrier between the two outer layers.

Sheets with grommets on top edge are ready to hang and have hook-and-loop fasteners on the sides for joining multiple sheets together.

| Sound Transmission Loss (STL), dB | Thick. | Wd. | Temp. Range, °F | Features | Specifications Met | Length, ft. | Each | |

Vinyl-Coated Fiberglass | ||||||||

|---|---|---|---|---|---|---|---|---|

| 29 | 2 1/8" | 48" | -20° to 180° | Five 5/8" Grommets on Top Edge, Hook and Loop Fasteners on Sides, Moisture Barrier | ASTM E84 25/35 for Flame and Smoke | 4 | 00000000 | 0000000 |

| 29 | 2 1/8" | 48" | -20° to 180° | Five 5/8" Grommets on Top Edge, Hook and Loop Fasteners on Sides, Moisture Barrier | ASTM E84 25/35 for Flame and Smoke | 8 | 00000000 | 000000 |

| Hooks for Vinyl Fabric Sheets (Pkg. of 10) | 00000000 | Pkg. | 000000 |

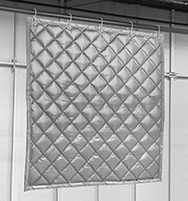

Easy-to-Hang Sound-Absorbing Sheets

Grommets along one side make it easy to install these sheets around your facility and quiet noisy areas. Made of vinyl-coated fiberglass, they resist abrasion, oil, dirt, moisture, and most solvents.

| Sound Absorbed | Thick. | Wd. | Lg., ft. | Wt., lbs. | Material | Temp. Range, °F | Features | Specifications Met | Each | |

Black | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Plain Backing | ||||||||||

| 65% | 1" | 48" | 2 | 2 | Vinyl-Coated Fiberglass | -20° to 180° | Two | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 65% | 1" | 48" | 4 | 4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 65% | 1" | 48" | 8 | 8 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 85% | 1 1/2" | 48" | 2 | 3 1/2 | Vinyl-Coated Fiberglass | -20° to 180° | Two | ASTM C423; ASTM E90; NFPA 101 Class A | 00000000 | 00000 |

| 85% | 1 1/2" | 48" | 4 | 7 1/4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 85% | 1 1/2" | 48" | 5 | 9 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 00000000 | 000000 |

| 85% | 1 1/2" | 48" | 8 | 14 1/4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

Gray | ||||||||||

Plain Backing | ||||||||||

| 65% | 1" | 48" | 2 | 2 | Vinyl-Coated Fiberglass | -20° to 180° | Two | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 00000 |

| 65% | 1" | 48" | 4 | 4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 65% | 1" | 48" | 8 | 8 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 85% | 1 1/2" | 48" | 2 | 3 1/2 | Vinyl-Coated Fiberglass | -20° to 180° | Two | ASTM C423; ASTM E90; NFPA 101 Class A | 00000000 | 00000 |

| 85% | 1 1/2" | 48" | 4 | 7 1/4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

| 85% | 1 1/2" | 48" | 5 | 9 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 00000000 | 000000 |

| 85% | 1 1/2" | 48" | 8 | 14 1/4 | Vinyl-Coated Fiberglass | -20° to 180° | Five | ASTM C423; ASTM E90; NFPA 101 Class A | 0000000 | 000000 |

Easy-to-Clean Ceiling Tiles

Often used in food processing areas and lavatories, these washable tiles have a durable, water-repellent surface. Simply spray, wipe down, or fog them with disinfectant. They’ve been treated to resist bacteria and mold growth. All meet USDA/FSIS guidelines for use in food processing areas.

Fiberglass tiles are thick, so they reduce noise better than drywall or plastic tiles. Because they absorb 95% of sound within a room, they’re ideal for use in healthcare facilities and other environments where noise control is crucial.

| Lg., ft. | Wd., ft. | Thick. | Sound Absorbed | Material | Color | Face Material | Edge Type | Specifications Met | Pkg. Qty. | Pkg. | |

| 2 | 2 | 1 1/2" | 95% | Fiberglass | White | Fiberglass | Flush | NFPA 101 Class A, USDA/FSIS Compliant 9 CFR 416.2 | 8 | 0000000 | 0000000 |

| 4 | 2 | 1 1/2" | 95% | Fiberglass | White | Fiberglass | Flush | NFPA 101 Class A, USDA/FSIS Compliant 9 CFR 416.2 | 8 | 0000000 | 000000 |

| Optional Sound Barrier Panels (Pkg. of 2) | 0000000 | Pkg. | 0000000 |

Adhesive-Mount Ceiling Tiles

When you don’t have space for a drop ceiling, use these tiles to improve the aesthetics and acoustics of your room. Stick them directly to existing drywall, plaster, concrete, and corrugated metal using construction adhesive (sold separately). Because these tiles absorb 95% of sound, they’re often used in spaces where noise control is crucial, such as healthcare facilities. They are coated in latex paint to stand up to bumps and scrapes.