How to Measure Threaded Pipe Size

More

How to Install Helical Inserts

More

About Helical Insert Length

More

How to Install Key-Locking Inserts

More

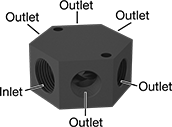

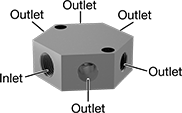

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Black-Phosphate Steel Easy-to-Install Thread-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Also known as E-Z Lok, these inserts use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. Installation requires a drill bit and a standard tap. Then set the insert with a bolt and two nuts, or use an installation bit.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

To drive slotted inserts, you can use a slotted screwdriver instead of using an installation bit or a bolt and two nuts.

Stainless Steel Helical Inserts

Also known as Heli-Coil inserts, these inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

Inserts that meet DIN 8140 adhere to international standards for dimensions.

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Installed Lg., mm | Drill Bit Size | For Max. Hole Dia. | Specifications Met | Pkg. Qty. | Pkg. | Each | Each | Each | ||||

18-8 Stainless Steel—Right-Hand Threaded | |||||||||||||||

| M20 | 2.5 | Coarse | 20 | 13/16" | 13/16" | DIN 8140, SAE MA3279-124 | 1 | 000000000 | 00000 | 000000000 | 0000000 | 000000000 | 0000000 | 000000000 | 0000000 |

| M20 | 2.5 | Coarse | 30 | 13/16" | 13/16" | DIN 8140, SAE MA3279-174 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

| M20 | 1.5 | Extra Fine | 30 | 13/16" | 13/16" | SAE MA3279-172 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

Stainless Steel Screw-Locking Helical Inserts

A distorted thread grips the screw to resist loosening. Also known as Heli-Coil inserts, these inserts have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw. Installation requires a drill bit, a helical insert tap, an installation tool, and a prong break-off tool.

Inserts | Through-Hole Taps | Closed-End Hole Taps | Installation Tools | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Installed Lg., mm | Drill Bit Size | For Max. Hole Dia. | Specifications Met | Pkg. Qty. | Pkg. | Each | Each | Each | ||||

18-8 Stainless Steel | |||||||||||||||

| M20 | 2.5 | Coarse | 20 | 13/16" | 13/16" | SAE MA3329-124 | 1 | 000000000 | 00000 | 000000000 | 0000000 | 000000000 | 0000000 | 000000000 | 0000000 |

| M20 | 2.5 | Coarse | 30 | 13/16" | 13/16" | SAE MA3329-174 | 1 | 000000000 | 0000 | 000000000 | 000000 | 000000000 | 000000 | 000000000 | 000000 |

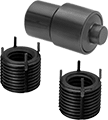

Helical Inserts with Installation Tools

Inserts come with a through-hole tap and installation tool. Also known as Heli-Coil inserts, they have coils that expand once installed to securely anchor the insert. All have a prong for ease of installation. An installation tool grips the prong and reduces the coil diameter, enabling the insert to fit in tapped holes. Remove the prong to insert the screw.

| Thread Size | Thread Pitch, mm | Thread Spacing | Installed Lg., mm | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |

18-8 Stainless Steel—Right-Hand Threaded | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| M20 | 2.5 | Coarse | 30 | 13/16" | 13/16" | 4 | Drill Bit, Through-Hole Tap, Installation Tool | 000000000 | 0000000 |

18-8 Stainless Steel Key-Locking Inserts

Made of stainless steel, these inserts have good corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Each | Installation Tools | |||||||||||

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

18-8 Stainless Steel with Thick Wall | |||||||||||||

| M20 | 1.5 | Extra Fine | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

| M20 | 2.5 | Coarse | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

Inserts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Each | Installation Tools | |||||||||||

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

Black-Phosphate Steel with Thick Wall | |||||||||||||

| M20 | 1.5 | Extra Fine | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

| M20 | 2.5 | Coarse | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

18-8 stainless steel inserts are more corrosion resistant than black-phosphate steel. They may be mildly magnetic.

Black-phosphate steel inserts are mildly corrosion resistant.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For Tap | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

18-8 Stainless Steel with Thick Wall | |||||||||||

| M20 | 1.5 | Extra Fine | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 3 | 000000000 | 0000000 |

| M20 | 2.5 | Coarse | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 3 | 000000000 | 000000 |

Black-Phosphate Steel with Thick Wall | |||||||||||

| M20 | 1.5 | Extra Fine | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 3 | 000000000 | 00000 |

| M20 | 2.5 | Coarse | M30 | 2 | 30mm | 28 mm | 28mm | 4 | 3 | 000000000 | 00000 |

Tapping Inserts for Soft Metal

Also known as Tap-Lok inserts, these inserts cut their own threads in soft metals such as aluminum, so there’s no need to tap the hole. Their cutting teeth lock them into your material, so they won’t budge when you install or remove a screw. Thread the insert onto a bolt with two nuts before driving it into a drilled hole with a wrench. For repeated installation, use an installation tool with a ratchet wrench or insert the installation tool into a drill press. These inserts have a zinc plating, so they resist corrosion in wet environments.

Inserts with thick walls are used to add threads to large holes. They’re often used to replace threads that have been drilled out.

| Thread Size | Thread Pitch, mm | Installed Lg., mm | Drill Bit Size | For Max. Hole Dia. | Each | |

Zinc-Plated Steel with Thick Wall | ||||||

|---|---|---|---|---|---|---|

| M20 | 2.5 | 27 | 63/64" | 63/64" | 000000000 | 000000 |