How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Threaded Pipe Size

More

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings.

- For Use With:

NPTF: Air, Hydraulic Fluid, Water

Metric: Air, Hydraulic Fluid, Oil, Water - Specifications Met:

NPTF: ASTM A108

Metric: DIN 7631, ISO 6149, ISO 9974

Thread Size | |||||

|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Material | Each | |

Metric Female | |||||

| M22 × 1.5 mm | M16 × 1.5 mm | 4,000 psi @ 72° F | Zinc Plated Steel | 00000000 | 000000 |

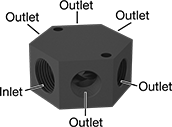

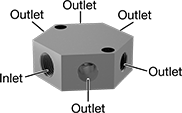

Low-Profile Hex Manifolds

When you’re short on vertical space, these manifolds are a good fit—they have outlets on the side instead of on top, so they have a lower profile than rectangular manifolds. Use them to distribute air, water, or hydraulic fluid to five locations from a single supply source. Manifolds have mounting holes, so you can mount from the top.

Anodized aluminum manifolds are the industry standard for the most common types of applications. They are lighter in weight than other metal manifolds and have good corrosion resistance. These manifolds are anodized for a black finish.

316 stainless steel manifolds have excellent corrosion resistance and can handle fuel, gasoline, coolant and other harsh substances.

- For Use With: Air, Water, Hydraulic Fluid

- Temperature Range: -10° to 200° F

- Maximum Pressure: 1,000 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Color | Each | |

| 5 | M22 | 1.5 | M20 | 1.5 | 50 | 38 | Standard | Black | 00000000 | 0000000 |

- For Use With: Air, Water, Hydraulic Fluid, Alcohol, Coolant, Cutting Oil, Deionized Water, Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Nitrogen

- Temperature Range: -100° to 500° F

- Maximum Pressure: 3,500 psi @ 72° F

- Maximum Vacuum: 27 in. of Hg @ 72° F

Inlet | Outlet | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Outlets | Thread Size | Thread Pitch, mm | Thread Size | Thread Pitch, mm | Wd., mm | Ht., mm | Outlet Spacing | Each | |

| 5 | M22 | 1.5 | M20 | 1.5 | 50 | 38 | Standard | 00000000 | 0000000 |

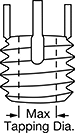

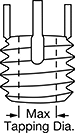

18-8 Stainless Steel Key-Locking Inserts

Made of stainless steel, these inserts have good corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Inserts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Each | Installation Tools | |||||||||||

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

18-8 Stainless Steel with Thick Wall | |||||||||||||

| M16 | 1.5 | Fine | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

| M16 | 2 | Coarse | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

| M22 | 1.5 | Fine | M32 | 2 | 32mm | 30 mm | 30mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Mil. Spec. Alloy Steel Key-Locking Inserts

The strongest key-locking inserts we offer, these inserts are made to stringent military specifications. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. Inserts may be mildly magnetic. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

Inserts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Each | Installation Tools | |||||||||||

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | 1-9 | 10-Up | Each | ||

Black-Phosphate Steel with Thick Wall | |||||||||||||

| M16 | 1.5 | Fine | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 000000000 | 000000 | 000000 | 000000000 | 000000 |

| M16 | 2 | Coarse | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

| M22 | 1.5 | Fine | M32 | 2 | 32mm | 30 mm | 30mm | 4 | 000000000 | 00000 | 00000 | 000000000 | 00000 |

Screw-Locking Key-Locking Inserts

Forming the strongest hold of any of our threaded inserts, these inserts have a distorted internal thread to lock screws into place and keys that drive into surrounding material to prevent slipping and rotating. This creates a mechanical lock, which is stronger than the chemical lock from adhesive on thread-locking inserts. Because they’re made of a solid piece of metal, these inserts are also stronger than helical inserts, which are made of coiled wire. They're often used in molds, tools and dies, and suspension systems in vehicles to create completely new threads, add strong threads in soft metal, or replace existing threads that are damaged or need to be resized.

A dry-film lubricant makes it easy to install them and screw fasteners in. To install, use a tap to create the threads in your material and an installation tool to drive the keys into the material. All are made to tight tolerances with strictly controlled materials. Many inch sizes also meet military or aerospace standards for dimensions and material.

These inserts resist corrosion in wet environments. Cadmium-plated steel inserts are stronger than 18-8 stainless steel inserts.

Inserts with thick walls are most commonly used; they’re stronger than thin-wall inserts and are used in larger holes.

Inserts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tap | Installation Tools | ||||||||||||

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg., mm | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | Specifications Met | Each | Each | ||

18-8 Stainless Steel with Thick Wall | |||||||||||||

| M16 | 2 | Coarse | M22 | 1.5 | 22 | 20.5 mm | 20.5 mm | 4 | __ | 000000000 | 000000 | 000000000 | 000000 |

Cadmium-Plated Steel with Thick Wall | |||||||||||||

| M16 | 1.5 | Fine | M22 | 1.5 | 22 | 20.5 mm | 20.5 mm | 4 | NA0150E160 | 000000000 | 00000 | 000000000 | 00000 |

| M16 | 2 | Coarse | M22 | 1.5 | 22 | 20.5 mm | 20.5 mm | 4 | __ | 000000000 | 00000 | 000000000 | 00000 |

Steel Key-Locking Insert Blanks

Tap the thread size you need into the solid body of these blanks. They’re a great choice when you need a custom combination of internal thread size and external diameter. Use them to repair or add new threads in soft metals, such as aluminum. They can also plug threaded holes without the hassle of welding. Made of steel, they’re stronger than stainless steel insert blanks. A black-phosphate coating makes them mildly corrosion resistant. These insert blanks have keys that grip the surrounding material, making them more secure than thread-locking inserts.

To install, you’ll need a drill bit, tap, installation tool, and hammer.

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

18-8 stainless steel inserts are more corrosion resistant than black-phosphate steel. They may be mildly magnetic.

Black-phosphate steel inserts are mildly corrosion resistant.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For Tap | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Thread Spacing | Thread Size | Thread Pitch, mm | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

18-8 Stainless Steel with Thick Wall | |||||||||||

| M16 | 1.5 | Fine | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 3 | 000000000 | 0000000 |

| M16 | 2 | Coarse | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 3 | 000000000 | 000000 |

Black-Phosphate Steel with Thick Wall | |||||||||||

| M16 | 1.5 | Fine | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 3 | 000000000 | 00000 |

| M16 | 2 | Coarse | M22 | 1.5 | 22mm | 20.5 mm | 20.5mm | 4 | 3 | 000000000 | 00000 |

| M22 | 1.5 | Fine | M32 | 2 | 32mm | 30 mm | 30mm | 4 | 3 | 000000000 | 000000 |

18-8 Stainless Steel Key-Locking Insert Blanks

Tap the thread size you need into the solid body of these blanks. They’re a great choice when you need a custom combination of internal thread size and external diameter. Use them to repair or add new threads in soft metals, such as aluminum. They can also plug threaded holes without the hassle of welding. Made of 18-8 stainless steel, these insert blanks resist corrosion from mild chemicals and water. They have keys that grip the surrounding material, making them more secure than thread-locking inserts.

To install, you’ll need a drill bit, tap, installation tool, and hammer.