Pressure-Regulating Valves for Chemicals

- For Use With: Chemicals

- Temperature Range:

Polypropylene Body: 35° to 180° F

PVC Body: 40° to 140° F

A plastic body and fluoroelastomer seal stand up to harsh chemicals. These valves automatically reduce a high, variable inlet pressure to a lower, stable outlet pressure. Adjust the outlet pressure within the range.

Polypropylene valves withstand higher temperatures than PVC valves.

Inlet | Outlet | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | Location | Max. Pressure, psi | Pipe Size | Location | Pressure Range, psi | End-to-End Lg. | Each | |

NPT Female | ||||||||

Polypropylene Body—Fluoroelastomer Seal | ||||||||

| 1/2 | Side | 125 | 1/2 | Side | 10 to 80 | 3" | 00000000 | 0000000 |

| 3/4 | Side | 125 | 3/4 | Side | 10 to 80 | 3 15/16" | 00000000 | 000000 |

| 1 | Side | 125 | 1 | Side | 10 to 80 | 3 15/16" | 00000000 | 000000 |

PVC Body—Fluoroelastomer Seal | ||||||||

| 1/2 | Side | 125 | 1/2 | Side | 10 to 80 | 3" | 00000000 | 000000 |

| 3/4 | Side | 125 | 3/4 | Side | 10 to 80 | 3 15/16" | 00000000 | 000000 |

| 1 | Side | 125 | 1 | Side | 10 to 80 | 3 15/16" | 00000000 | 000000 |

| 1 1/2 | Side | 125 | 1 1/2 | Side | 10 to 80 | 6 1/8" | 00000000 | 00000000 |

| 2 | Side | 125 | 2 | Side | 10 to 80 | 6" | 00000000 | 00000000 |

Float Valve Bodies for Chemicals

Often found in tanks that are frequently washed down, these float valve bodies are 316 stainless steel, so they resist corroding from harsh cleaners. To create custom float valves, combine these valve bodies with floats and rods. Thread them onto pipe to direct water to a specific location. They’re frequently used to send water to the bottom of a tank to limit splashing and disruptions at the surface level. When the valve opens and closes, the plunger rotates freely. This means the internal seal wears evenly, extending the life of the valve body.

Valve bodies with a Teflon® PTFE seal withstand higher temperatures than those with a Viton® fluoroelastomer seal.

Inlet | Outlet | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Flow Rate | Max. Pressure, psi | For Rod Thread Size | Material | Plunger Material | Temp. Range, °F | Each | |

Viton® Fluoroelastomer Seal | |||||||||||||

90° Elbow | |||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 48 gpm @ 50 psi | 85 | 1/4"-20 | 316 Stainless Steel | 316 Stainless Steel | 35° to 450° | 0000000 | 0000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 48 gpm @ 50 psi | 85 | 1/4"-20 | 316 Stainless Steel | 316 Stainless Steel | 35° to 450° | 0000000 | 000000 |

| 1 | NPT | Female | 3/4 | NPT | Female | 57.5 gpm @ 50 psi | 85 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 450° | 0000000 | 000000 |

| 2 | NPT | Female | 2 | NPT | Female | 140 gpm @ 50 psi | 100 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 450° | 0000000 | 00000000 |

Teflon® PTFE Seal | |||||||||||||

90° Elbow | |||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 48 gpm @ 50 psi | 85 | 1/4"-20 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 48 gpm @ 50 psi | 85 | 1/4"-20 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 000000 |

| 1 | NPT | Female | 3/4 | NPT | Female | 57.5 gpm @ 50 psi | 85 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 000000 |

| 1 1/4 | NPT | Female | 1 1/4 | NPT | Female | 140 gpm @ 50 psi | 100 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 00000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 140 gpm @ 50 psi | 100 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 00000000 |

| 2 | NPT | Female | 2 | NPT | Female | 140 gpm @ 50 psi | 100 | 3/8"-16 | 316 Stainless Steel | 316 Stainless Steel | 35° to 550° | 0000000 | 00000000 |

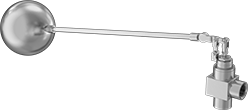

Float Valves for Chemicals

Made of stainless steel, these float valves have excellent corrosion resistance even when exposed to chemicals.

Valves for open tanks are for use only in an open tank.

Valves for closed tanks are designed to withstand the pressure in a closed tank.

Inlet | Outlet | Float Rod | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Flow Rate | Max. Pressure, psi | Float Dia. | Lg. | Pipe Size | Thread Type | Float Material | Seal Material | Temp. Range, °F | Each | |

Open Tank | ||||||||||||||||

For Use With Acetone, Alcohol, Chemicals, Hydraulic Fluid | ||||||||||||||||

316 Stainless Steel Elbow Valve Body | ||||||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 30 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 0000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 50 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 000000 |

| 1 | NPT | Female | 1 | NPT | Female | 75 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 125 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 00000000 |

316 Stainless Steel Straight Valve Body | ||||||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 30 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 50 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 000000 |

| 1 | NPT | Female | 1 | NPT | Female | 75 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 125 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 0000000 | 00000000 |

Closed Tank | ||||||||||||||||

For Use With Acetone, Alcohol, Chemicals, Hydraulic Fluid | ||||||||||||||||

316 Stainless Steel Elbow Valve Body | ||||||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 30 gpm @ 50 psi | 100 | 5" | 16" | 1/8 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 50 gpm @ 50 psi | 100 | 5" | 16" | 1/8 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 000000 |

| 1 | NPT | Female | 1 | NPT | Female | 75 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 125 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 00000000 |

316 Stainless Steel Straight Valve Body | ||||||||||||||||

| 1/2 | NPT | Female | 1/2 | NPT | Female | 30 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 000000 |

| 3/4 | NPT | Female | 3/4 | NPT | Female | 50 gpm @ 50 psi | 100 | 5" | 16" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 000000 |

| 1 | NPT | Female | 1 | NPT | Female | 75 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 00000000 |

| 1 1/2 | NPT | Female | 1 1/2 | NPT | Female | 125 gpm @ 50 psi | 100 | 6" | 18" | 1/4 | NPT | 304 Stainless Steel | PTFE Plastic | 35° to 350° | 00000000 | 00000000 |