How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

How to Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Barbed Flow-Control Orifices

Insert the barbed ends of these orifices into rubber and soft plastic tubing, and secure them with a clamp. Also known as flow restrictors and precision orifice valves, they are used to throttle, vent, bleed, or regulate the flow of liquids and gases.

- For Use With: Air, Argon, Coolant, Diesel Fuel, Gasoline, Mineral Oils, Natural Gas, Oil, Oxygen, Steam, Water

- Max. Pressure: 500 psi @ 70° F

- Temperature Range: Not Rated to 500° F

Available Orifice Diameters | ||

|---|---|---|

| Orifice Dia. | Water Flow | Air Flow |

| 0.01" | 0.016 gpm @ 40 psi | 0.3 scfm @ 40 psi |

| 0.016" | 0.035 gpm @ 40 psi | 0.5 scfm @ 40 psi |

| 0.018" | 0.046 gpm @ 40 psi | 0.6 scfm @ 40 psi |

| 0.02" | 0.056 gpm @ 40 psi | 0.6 scfm @ 40 psi |

| 0.021" | 0.061 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.023" | 0.076 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.024" | 0.082 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.025" | 0.089 gpm @ 40 psi | 0.8 scfm @ 40 psi |

| 0.026" | 0.101 gpm @ 40 psi | 0.8 scfm @ 40 psi |

| 0.028" | 0.114 gpm @ 40 psi | 0.9 scfm @ 40 psi |

| 0.029" | 0.12 gpm @ 40 psi | 0.9 scfm @ 40 psi |

| 0.032" | 0.152 gpm @ 40 psi | 1.1 scfm @ 40 psi |

| 0.033" | 0.158 gpm @ 40 psi | 1.1 scfm @ 40 psi |

| 0.035" | 0.177 gpm @ 40 psi | 1.2 scfm @ 40 psi |

| 0.038" | 0.202 gpm @ 40 psi | 1.2 scfm @ 40 psi |

| 0.04" | 0.228 gpm @ 40 psi | 1.3 scfm @ 40 psi |

| 0.042" | 0.247 gpm @ 40 psi | 1.4 scfm @ 40 psi |

| 0.047" | 0.304 gpm @ 40 psi | 1.5 scfm @ 40 psi |

| 0.052" | 0.373 gpm @ 40 psi | 1.6 scfm @ 40 psi |

| 0.055" | 0.43 gpm @ 40 psi | 1.7 scfm @ 40 psi |

| 0.063" | 0.557 gpm @ 40 psi | 2 scfm @ 40 psi |

| 0.125" | 2.34 gpm @ 40 psi | 4 scfm @ 40 psi |

| For Tube ID | Lg. | Each | |

Barbed × Barbed | |||

|---|---|---|---|

| 1/4" | 1 5/16" | 0000000 | 000000 |

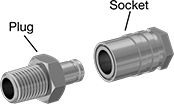

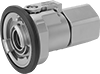

Quick-Disconnect Hose Couplings for Coolant

Also known as coolant-line mold couplings, these couplings are often used to install and remove coolant lines in molding and die casting applications. A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them when you need frequent access to a line. All of the quick-disconnect coolant plugs are compatible with any of the quick-disconnect coolant sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Sockets with a shut-off have a valve that stops the flow of coolant when the coupling is separated.

Sockets are sleeve-lock style. To connect, slide back the sleeve on the socket, insert the plug, and release the sleeve. To disconnect, slide back the sleeve and pull out the plug.

Sockets with a barbed end insert into plastic or rubber hose and secure with a clamp.

Brass plugs and sockets have better corrosion resistance than zinc-plated steel, and are softer, so they’re easier to thread together.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 200 psi @ 72° F

- Temperature Range: -30° to 400° F

- Attachment Type: Use Worm-Drive Clamps or Band-and-Buckle Clamps

- Compatible With: Hansen FT

- Maximum Pressure: 200 psi @ 72° F

- Temperature Range: -30° to 400° F

- Compatible With: Hansen FT

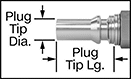

For Plug Tip | With Shut-Off | ||||

|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | For Hose ID | Each | |

Brass | |||||

| 1/4 | 7/32" | 3/8" | 1/4" | 0000000 | 000000 |

Minimal-Spill Quick-Disconnect Hose Couplings for Coolant

Reduce the risk of spills near electronics when connecting and disconnecting liquid cooling lines. Also known as double shut-off couplings, these couplings have a shut-off valve on both sides that stops the flow of coolant if they’re separated. Often used to connect servers to a cooling manifold in data centers, they comply with the performance specifications of OCP (Open Computing Project). To avoid mixing up your lines, choose blue couplings for cold supply and red couplings for hot return. A complete coupling consists of a plug and socket or two adapters (all sold separately).

Install plugs on manifolds and servers. They’re also known as nipples. Attach sockets to either end of a hose to connect your manifold to each server. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug is ejected.

Use adapters for supplying your manifold. They have a lever-activated shut-off valve, which must be closed for a coupling to be separated. To connect, push two adapters together with a quarter twist, then press the lever to open the valve and start the flow.

UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

BSPP male threads have a gasket to protect against leaks.

Barbed fittings require a pinch clamp when used with pressures above 70 psi. When used below this pressure with our Coolant Hose for Electronics, no clamp is needed. The more you pull on these fittings, the tighter the hose will grip.

- Maximum Pressure: See Table

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- Compatible With: Danfoss Hansen UQD

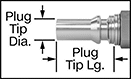

Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Thread Size | Dash Size | Max. Pressure | Each | |

Blue | |||||||

| 1/8 | 27/32" | 1/4" | 7/16"-20 | 04 | 290 psi @ 72° F | 0000000 | 000000 |

| 1/4 | 1 1/8" | 7/16" | 9/16"-18 | 06 | 230 psi @ 72° F | 0000000 | 00000 |

| 3/8 | 1 9/32" | 9/16" | 3/4"-16 | 08 | 100 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 1 7/16" | 11/16" | 7/8"-14 | 10 | 100 psi @ 72° F | 0000000 | 00000 |

Red | |||||||

| 1/8 | 27/32" | 1/4" | 7/16"-20 | 04 | 290 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 1 1/8" | 7/16" | 9/16"-18 | 06 | 230 psi @ 72° F | 0000000 | 00000 |

| 3/8 | 1 9/32" | 9/16" | 3/4"-16 | 08 | 100 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 1 7/16" | 11/16" | 7/16"-14 | 10 | 100 psi @ 72° F | 0000000 | 00000 |

- Maximum Pressure: See Table

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- Compatible With: Danfoss Hansen UQD

Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | Pipe Size | Dash Size | Max. Pressure | Each | |

Blue | |||||||

| 1/8 | 27/32" | 1/4" | 1/8 | 02 | 290 psi @ 72° F | 0000000 | 000000 |

| 1/4 | 1 1/8" | 7/16" | 3/8 | 06 | 230 psi @ 72° F | 0000000 | 00000 |

| 3/8 | 1 9/32" | 9/16" | 3/8 | 06 | 100 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 1 7/16" | 11/16" | 1/2 | 08 | 100 psi @ 72° F | 0000000 | 00000 |

Red | |||||||

| 1/8 | 27/32" | 1/4" | 1/8 | 02 | 290 psi @ 72° F | 0000000 | 00000 |

| 1/4 | 1 1/8" | 7/16" | 3/8 | 06 | 230 psi @ 72° F | 0000000 | 00000 |

| 3/8 | 1 9/32" | 9/16" | 3/8 | 06 | 100 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 1 7/16" | 11/16" | 1/2 | 08 | 100 psi @ 72° F | 0000000 | 00000 |

- Maximum Pressure: See Table

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- For Hose Type: Coolant Hose for Electronics

- Attachment Type: Use Tight-Seal Vibration-Resistant Pinch Clamps for Firm Hose and Tube

- Compatible With: Danfoss Hansen UQD

Couplings | ||||||||

|---|---|---|---|---|---|---|---|---|

For Plug Tip | Hose | |||||||

| Coupling Size | For Hose ID | Lg. | Dia. | Max. Pressure | Each | Per Ft. | ||

Blue | ||||||||

| 1/8 | 1/4" | 27/32" | 1/4" | 290 psi @ 72° F | 0000000 | 000000 | 0000000 | 00000 |

| 1/4 | 3/8" | 1 1/8" | 7/16" | 230 psi @ 72° F | 0000000 | 00000 | 0000000 | 0000 |

| 3/8 | 1/2" | 1 9/32" | 9/16" | 100 psi @ 72° F | 0000000 | 000000 | 0000000 | 0000 |

| 1/2 | 5/8" | 1 7/16" | 11/16" | 100 psi @ 72° F | 0000000 | 000000 | 0000000 | 0000 |

Red | ||||||||

| 1/8 | 1/4" | 27/32" | 1/4" | 290 psi @ 72° F | 0000000 | 00000 | 0000000 | 0000 |

| 1/4 | 3/8" | 1 1/8" | 7/16" | 230 psi @ 72° F | 0000000 | 00000 | 0000000 | 0000 |

| 3/8 | 1/2" | 1 9/32" | 9/16" | 100 psi @ 72° F | 0000000 | 000000 | 0000000 | 0000 |

| 1/2 | 5/8" | 1 7/16" | 11/16" | 100 psi @ 72° F | 0000000 | 000000 | 0000000 | 0000 |

- Maximum Pressure: 150 psi @ 72° F

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- Compatible With: Danfoss Hansen FD83

| Coupling Size | For Hose ID | Pipe Size | Dash Size | Each | |

| 1 | 1" | 1 | 16 | 0000000 | 0000000 |

- Maximum Pressure: 150 psi @ 72° F

- Temperature Range: -40° to 300° F

- Material: 303 Stainless Steel

- For Hose Type: Coolant Hose for Electronics

- Attachment Type: Use Tight-Seal Vibration-Resistant Pinch Clamps for Firm Hose and Tube

- Compatible With: Danfoss Hansen FD83