How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Actuated On/Off Valves

More

How to Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

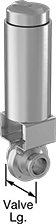

Sanitary Air-Driven On/Off Valves

- For Use With: Air, Argon, Beverage, Carbon Dioxide, Citric Acid, Drinking Water, Ethanol, Food, Helium, Isopropyl Alcohol, Methanol, Mineral Oils, Natural Gas, Neon, Nitrogen, Oil, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Water, Xenon

- Seal Material: Silicone Rubber

- Specifications Met: FDA Compliant 21 CFR 177.2600

Use air pressure to automatically control the flow of liquids in sanitary environments, such as food and beverage processing plants. These valves connect to your liquid line with quick-clamp sanitary fittings, also known as tri-clamp connections, which are easier to remove and sanitize than threaded connections. You’ll need a gasket and clamp to connect them to another quick-clamp fitting (not included). They are also self-draining, so liquids drain completely and don’t pool on actuators or valves. The polished interior is extremely smooth, so there’s nowhere for bacteria to hide. Made of stainless steel, these valves won’t corrode from frequent washdowns with harsh cleaners. Their seal is FDA compliant for direct contact with food.

They are single-acting actuators, which open from the force of compressed air and close with an internal spring. You’ll also need either an electric pilot valve or a manual on/off valve (not included) to control the air flowing to the actuator. They open and close faster than motor driven valves and can be operated remotely, so they’re often used in automated liquid lines. Since they are normally closed unless air pressure opens them, these valves will stop the flow if there is a power outage or the air supply is cut. There must be a minimum pressure drop between the inlet and the outlet for these valves to work, meaning that the upstream pressure must be greater than the downstream pressure.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

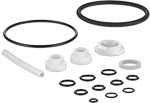

Actuator repair kits include replacements for all parts inside the actuator.

Valves | Actuator Repair Kits | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Gender | Connection Style | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | Valve Lg. | Overall Ht. | For Air Connection Tube OD, mm | Air Connection Gender | Air Pressure Range, psi | Each | Each | ||

316 Stainless Steel Body | ||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed) | ||||||||||||||

| 1" | Female | Quick Clamp | 27 | 120 psi @ 70° F | -40° to 450° | 2 11/16" | 14" | 6 | Female | 70 to 115 | 0000000 | 0000000 | 0000000 | 000000 |

| 1 1/2" | Female | Quick Clamp | 92 | 120 psi @ 70° F | -40° to 450° | 3" | 14 13/16" | 6 | Female | 70 to 115 | 0000000 | 000000 | 0000000 | 00000 |

| 2" | Female | Quick Clamp | 248 | 120 psi @ 70° F | -40° to 450° | 3 1/8" | 15 1/8" | 6 | Female | 70 to 115 | 0000000 | 000000 | 0000000 | 00000 |

| 3" | Female | Quick Clamp | 411 | 120 psi @ 70° F | -40° to 450° | 3 1/4" | 15 3/4" | 6 | Female | 70 to 115 | 0000000 | 00000000 | 0000000 | 00000 |

| 4" | Female | Quick Clamp | 880 | 120 psi @ 70° F | -40° to 450° | 3 1/2" | 17" | 6 | Female | 70 to 115 | 0000000 | 00000000 | 0000000 | 00000 |

Barbed Flow-Control Orifices

Insert the barbed ends of these orifices into rubber and soft plastic tubing, and secure them with a clamp. Also known as flow restrictors and precision orifice valves, they are used to throttle, vent, bleed, or regulate the flow of liquids and gases.

- For Use With: Air, Argon, Coolant, Diesel Fuel, Gasoline, Mineral Oils, Natural Gas, Oil, Oxygen, Steam, Water

- Max. Pressure: 500 psi @ 70° F

- Temperature Range: Not Rated to 500° F

Available Orifice Diameters | ||

|---|---|---|

| Orifice Dia. | Water Flow | Air Flow |

| 0.01" | 0.016 gpm @ 40 psi | 0.3 scfm @ 40 psi |

| 0.016" | 0.035 gpm @ 40 psi | 0.5 scfm @ 40 psi |

| 0.018" | 0.046 gpm @ 40 psi | 0.6 scfm @ 40 psi |

| 0.02" | 0.056 gpm @ 40 psi | 0.6 scfm @ 40 psi |

| 0.021" | 0.061 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.023" | 0.076 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.024" | 0.082 gpm @ 40 psi | 0.7 scfm @ 40 psi |

| 0.025" | 0.089 gpm @ 40 psi | 0.8 scfm @ 40 psi |

| 0.026" | 0.101 gpm @ 40 psi | 0.8 scfm @ 40 psi |

| 0.028" | 0.114 gpm @ 40 psi | 0.9 scfm @ 40 psi |

| 0.029" | 0.12 gpm @ 40 psi | 0.9 scfm @ 40 psi |

| 0.032" | 0.152 gpm @ 40 psi | 1.1 scfm @ 40 psi |

| 0.033" | 0.158 gpm @ 40 psi | 1.1 scfm @ 40 psi |

| 0.035" | 0.177 gpm @ 40 psi | 1.2 scfm @ 40 psi |

| 0.038" | 0.202 gpm @ 40 psi | 1.2 scfm @ 40 psi |

| 0.04" | 0.228 gpm @ 40 psi | 1.3 scfm @ 40 psi |

| 0.042" | 0.247 gpm @ 40 psi | 1.4 scfm @ 40 psi |

| 0.047" | 0.304 gpm @ 40 psi | 1.5 scfm @ 40 psi |

| 0.052" | 0.373 gpm @ 40 psi | 1.6 scfm @ 40 psi |

| 0.055" | 0.43 gpm @ 40 psi | 1.7 scfm @ 40 psi |

| 0.063" | 0.557 gpm @ 40 psi | 2 scfm @ 40 psi |

| 0.125" | 2.34 gpm @ 40 psi | 4 scfm @ 40 psi |

| For Tube ID | Lg. | Each | |

Barbed × Barbed | |||

|---|---|---|---|

| 1/4" | 1 5/16" | 0000000 | 000000 |

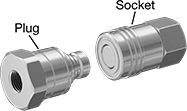

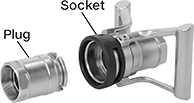

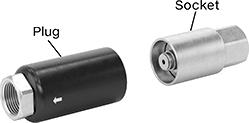

International Standard ISO Minimal-Spill

Quick-Disconnect Hose Couplings for Chemicals

To minimize fluid loss when connecting and disconnecting your line, these couplings have flat faces for a close fit and shut-off valves to stop the flow—they meet ISO 16028, which is an international standard for hose couplings. They’re also known as flush-face and double shut-off couplings. A complete coupling consists of a plug and socket (both sold separately). They connect and disconnect quickly, so use them if you need to access a line frequently. Made of 316 stainless steel, they have excellent corrosion resistance and withstand a variety of chemicals.

Plugs are also known as nipples.

Sockets are push-to-connect style. To connect, push the plug into the socket until you hear a click. To disconnect, slide the sleeve on the socket forward until the plug ejects. These sockets have an internal fluoroelastomer gasket that resists a wide range of chemicals, including benzene, butyl alcohol, and ethylene glycol.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Never attempt to connect or disconnect couplings when operating at maximum pressure. Stop the flow before you disconnect the line.

- Maximum Pressure: 3,600 psi @ 72° F

- Temperature Range: 0° to 400° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

- Maximum Pressure: 3,600 psi @ 72° F

- Temperature Range: 0° to 400° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

- Maximum Pressure: 3,600 psi @ 72° F

- Temperature Range: 0° to 400° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

- Maximum Pressure: 3,600 psi @ 72° F

- Temperature Range: 0° to 400° F

- Compatible With: ISO 16028 Parker FEM, ISO 16028 Perfecting HT, ISO 16028 Snap-Tite 74

- Specifications Met: ISO 16028

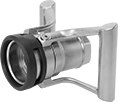

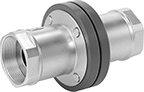

Minimal-Spill Push-and-Turn Hose Couplings for Chemicals

Quickly connect and disconnect hose lines used with a variety of chemicals, from adhesives to isopropyl alcohol and ink. Any part of these couplings that contacts fluid is made from 316 stainless steel, C-276 Hastelloy, PTFE, or fluoroelastomer to withstand the chemicals in your line. Tough enough to handle frequent use, these couplings are designed to be virtually spill free. Also known as dry disconnects and double-shut off couplings, both the plug and the socket have a shut-off valve that stops the flow of liquids when they’re separated. To connect, push the plug into the socket and lock with a quarter turn. The socket swivels, so you won’t have to twist your hose to attach the plug. It also has a rubber lip and large handles to prevent damage if it’s dropped.

A complete coupling consists of a plug and a socket (both sold separately). They’re compatible with MannTek, Avery Hardoll, Todo-matic, and other dry-disconnect couplings that meet NATO standard STANAG 3756.

Aluminum couplings are lighter in weight than stainless steel and have good corrosion resistance.

316 stainless steel couplings have excellent corrosion resistance.

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

Bolt Hole | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Plug OD | Pipe Size | Flange OD | Flanged Connection Surface | Pressure Class | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

Aluminum | ||||||||||

| 2 3/4" | 2 | 6" | Flat | 150 | 5/8" | 3/4" | 4 | 4 3/4" | 0000000 | 0000000 |

| 4 11/16" | 3 | 7 1/2" | Flat | 150 | 5/8" | 3/4" | 4 | 6" | 0000000 | 000000 |

316 Stainless Steel | ||||||||||

| 2 3/4" | 2 | 6" | Raised | 150 | 5/8" | 3/4" | 4 | 4 3/4" | 0000000 | 000000 |

| 4 11/16" | 3 | 7 1/2" | Raised | 150 | 5/8" | 3/4" | 4 | 6" | 0000000 | 00000000 |

- For Use With:

Aluminum: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil

316 Stainless Steel: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil - Maximum Pressure:

Aluminum: 230 psi @ 72° F

316 Stainless Steel: 360 psi @ 72° F - Temperature Range: -15° to 400° F

- For Use With: Acetone, Adhesives, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Ink, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil

- Maximum Pressure: 360 psi @ 72° F

- Temperature Range: -15° to 400° F

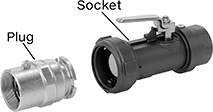

Minimal-Spill Push-and-Turn Hose Couplings for Petroleum

Also known as dry disconnects and double shut-off couplings, these couplings make connecting and disconnecting your line quick and virtually spill-free. Simply push the socket onto the plug and twist 90° to connect. Both the plug and the socket have a shut-off valve that only opens when they’re connected and you turn the handle on the socket. Before you disconnect the coupling, you’ll need to close the valve by moving the handle back to its original position. A close fit between the plug and socket means there's little room for fluid to escape when you disconnect them. The socket swivels, so you won’t have to twist your hose to attach the plug.

Built to stand up to petroleum products, such as diesel fuel and gasoline, their body and gasket are made from materials that won’t corrode from oil.

A complete coupling consists of a plug and a socket (both sold separately). These couplings are compatible with Emco Wheaton Dry-Break couplers.

Couplings with a fluoroelastomer gasket withstand higher temperatures than those with a Buna-N gasket.

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Vegetable Oil

- Maximum Pressure: 85 psi @ 72° F

- Temperature Range: See table

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Vegetable Oil

- Maximum Pressure: 85 psi @ 72° F

- Temperature Range: See table

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Mineral Oil, Vegetable Oil

- Maximum Pressure: 85 psi @ 72° F

- Temperature Range: See table

Breakaway Hose Couplings for Chemicals and Petroleum

Minimize chemical and petroleum spills during accidental disconnects, such as a driver pulling away during loading. These couplings have a shut-off valve on each half to stop flow when they’re separated. Attach one end to your hose and the other to a supply pipe or a second hose.

Aluminum couplings are lightweight and have good corrosion resistance.

316 stainless steel couplings have excellent corrosion resistance.

1 NPT couplings cannot be reconnected.

2 NPT and 3 NPT couplings have bolts designed to break before your hose does. They can be repaired with replacement bolt kits and replacement seal kits (both sold separately).

- For Use With: See table

- Maximum Pressure: See table

- Temperature Range: See table

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Plug | Socket | Max. Pressure | Temp. Range, °F | Repairable | For Use With | Each | ||

NPT Female Threaded Pipe | ||||||||

Aluminum Plug and Socket | ||||||||

| A | 1 | 1 | Not Rated | Not Rated | Nonrepairable | Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Mineral Oil, Mineral Spirits | 0000000 | 0000000 |

| B | 2 | 2 | 230 psi @ 72° F | -50° to 200° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil | 0000000 | 000000 |

| B | 3 | 3 | 230 psi @ 72° F | -50° to 200° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Varnish, Vegetable Oil | 0000000 | 00000000 |

316 Stainless Steel Plug and Socket | ||||||||

| B | 2 | 2 | 360 psi @ 72° F | -50° to 480° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil | 0000000 | 00000000 |

| B | 3 | 3 | 360 psi @ 72° F | -50° to 480° | Repairable | Acetone, Benzene, Boric Acid, Butyl Alcohol, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Mineral Spirits, Nitric Acid, Sodium Hydroxide, Varnish, Vegetable Oil | 0000000 | 00000000 |