Strain Gauges

Measure strain across one or multiple directions by gluing or welding these strain gauges onto a structure. They’re often used in structural testing and monitoring applications to measure the deformation or displacement of material caused by force.

Weld-on strain gauges are best for places where glue might not set or where high temperatures prevent the use of adhesives.

Solder wire leads onto strain gauges with solder terminals after the strain gauge has bonded to your surface. After soldering, apply a protective coating. Strain gauges with wire leads save you the effort of soldering wire to the strain gauge and checking to see that it’s bonded securely.

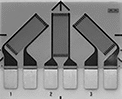

Linear pattern strain gauges measure strain in one direction. They’re often used for fatigue testing. Multi-direction pattern strain gauges measure strain in multiple directions, making them great for stress tests. Tee pattern strain gauges measure tension or compression, like in bolts or suspension rods. They’re useful for measuring bending in large structures, such as wind turbine towers.

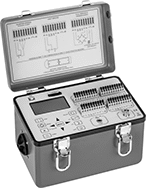

Optional indicators record changes in force, doing the combined job of a multimeter, signal conditioner, and bridge amplifier. They’re battery-operated and portable. Using the included software, operate and configure them straight from your PC. These indicators have no internal memory, but they include an SD card to store your readings. Connect them to strain gauges using wire leads. If installing them in dirty or wet environments, just close the lid after attaching the lead wires.

Installation tape holds the strain gauge in place while you install it and minimizes the risk of contaminating your surface.

Surface cleaners help remove contaminants introduced during mounting. Phosphoric acid cleaners, also known as conditioners, accelerate the surface cleaning process. Ammonia cleaners neutralize any chemicals that have been introduced, helping your gauge mount properly.

Protective coatings extend the life of your strain gage by protecting it from moisture and dust.

Grid | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Resistance, ohms | Accuracy | Lg. | Wd. | Lg. | Wd. | Material | Temperature Range, °F | Pkg. Qty. | Pkg. | |

Linear Grid Pattern | ||||||||||

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||

| 350 | ±0.2% | 0.125" | 0.1" | 0.275" | 0.12" | C70600 Copper Nickel | -100° to 350° | 5 | 0000000 | 000000 |

| 350 | ±0.2% | 0.25" | 0.12" | 0.415" | 0.12" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 00000 |

| 350 | ±0.3% | 0.062" | 0.12" | 0.22" | 0.12" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

Multi-Direction Grid Pattern | ||||||||||

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||

| 350 | ±0.2% | 0.25" | 0.12" | 0.5" | 0.76" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

| 350 | ±0.4% | 0.062" | 0.062" | 0.222" | 0.42" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

| 350 | ±0.4% | 0.125" | 0.06" | 0.3" | 0.56" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

Tee Grid Pattern | ||||||||||

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||

| 350 | ±0.4% | 0.062" | 0.08" | 0.205" | 0.225" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

| 350 | ±0.4% | 0.125" | 0.165" | 0.325" | 0.365" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

| 350 | ±0.4% | 0.25" | 0.29" | 0.45" | 0.65" | C70600 Copper Nickel | -100° to 350° | 5 | 00000000 | 000000 |

Grid | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Resistance, ohms | Accuracy | Lg. | Wd. | Lg. | Wd. | Material | Temperature Range, °F | Pkg. Qty. | Pkg. | |

Linear Grid Pattern | ||||||||||

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||

| 350 | ±0.4% | 0.23" | 0.125" | 0.63" | 0.34" | C70600 Copper Nickel | -60° to 180° | 5 | 00000000 | 0000000 |

Grid | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Resistance, ohms | Accuracy | Lg. | Wd. | Lg. | Wd. | Number of Wire Leads | Wire Lead Lg., ft. | Material | Temperature Range, °F | Pkg. Qty. | Pkg. | |

Linear Grid Pattern | ||||||||||||

For Use With Aluminum, Brass, Tin | ||||||||||||

| 120 | ±0.3% | 0.235" | 0.1" | 0.301" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 0000000 |

| 350 | ±0.3% | 0.06" | 0.1" | 0.166" | 0.13" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 350 | ±0.3% | 0.235" | 0.1" | 0.301" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||||

| 120 | ±0.3% | 0.06" | 0.1" | 0.166" | 0.13" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 120 | ±0.3% | 0.125" | 0.1" | 0.205" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 120 | ±0.3% | 0.235" | 0.1" | 0.301" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 350 | ±0.3% | 0.06" | 0.1" | 0.166" | 0.13" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 350 | ±0.3% | 0.125" | 0.1" | 0.205" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

For Use With Composites, Nickel Iron, Titanium Silicate | ||||||||||||

| 350 | ±0.3% | 0.235" | 0.1" | 0.301" | 0.1" | 2 | 3 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

Grid | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Resistance, ohms | Accuracy | Lg. | Wd. | Lg. | Wd. | Number of Wire Leads | Wire Lead Lg., ft. | Material | Temperature Range, °F | Pkg. Qty. | Pkg. | |

Linear Grid Pattern | ||||||||||||

For Use With Aluminum, Brass, Tin | ||||||||||||

| 350 | ±0.2% | 0.03" | 0.063" | 0.095" | 0.063" | 3 | 3 | Nickel Chromium | -100° to 400° | 1 | 0000000 | 000000 |

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||||

| 120 | ±0.3% | 0.015" | 0.02" | 0.052" | 0.042" | 3 | 9 | Nickel Chromium | -60° to 180° | 1 | 00000000 | 000000 |

| 350 | ±0.2% | 0.03" | 0.063" | 0.095" | 0.063" | 3 | 9 | Nickel Chromium | -100° to 400° | 1 | 0000000 | 00000 |

| 350 | ±0.3% | 0.06" | 0.1" | 0.166" | 0.13" | 3 | 9 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 350 | ±0.3% | 0.125" | 0.1" | 0.233" | 0.13" | 3 | 9 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

| 350 | ±0.3% | 0.235" | 0.1" | 0.343" | 0.13" | 3 | 9 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

For Use With Composites, Nickel Iron, Titanium Silicate | ||||||||||||

| 350 | ±0.3% | 0.235" | 0.1" | 0.301" | 0.1" | 3 | 9 | C70600 Copper Nickel | -60° to 180° | 10 | 0000000 | 000000 |

Grid | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Resistance, ohms | Accuracy | Lg. | Wd. | Lg. | Wd. | Number of Wire Leads | Wire Lead Lg., ft. | Material | Temperature Range, °F | Pkg. Qty. | Pkg. | |

Multi-Direction Grid Pattern | ||||||||||||

For Use With Cast Iron, Composites, Printed Circuit Board, Steel | ||||||||||||

| 350 | ±0.3% | 0.125" | 0.079" | 0.231" | 0.429" | 9 | 9 | C70600 Copper Nickel | -60° to 180° | 5 | 00000000 | 0000000 |

| 350 | ±0.5% | 0.014" | 0.012" | 0.071" | 0.143" | 9 | 9 | Nickel Chromium | -100° to 400° | 1 | 00000000 | 00000 |

No. of | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inputs | Terminals per Input | Resistance, ohms | Accuracy | Sampling Interval | Response Time | Display Type | Lg. | Wd. | Ht. | Weight, lbs. | For Wire Gauge | Batteries Included | Software Included | Temperature Range, °F | Includes | Each | |

| 4 | 10 | 120, 350, 1,000 | ±0.1% | 1 sec - 1 hr. | 1 sec. | LCD | 9" | 6" | 6" | 4.4 | 28-16 | Yes | Yes | 32° to 120° | 32 GB SD Card, 6-ft. Lg. USB Cord | 00000000 | 000000000 |

Container | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Begins to Harden | Reaches Full Strength | Consistency (Viscosity) | Temperature Range, °F | For Use On | Includes | Each | |

| 1 | Bottle | 1 min. | 5 min. | Thin Liquid (130 cP) | -25° to 150° | Aluminum, Composites, Glass, Steel | Catalyst | 0000000 | 0000000 |

| Width | Length, ft. | Color | Temperature Range | Features | Each | |

| 3/4" | 216 | Clear | 400° F | Tape Dispenser | 0000000 | 0000000 |

Dry Time | |||||

|---|---|---|---|---|---|

| Container Size, fl. oz. | Touch, min. | Overall, hrs. | Pkg. Qty. | Pkg. | |

| 1 | 20 | 2 | 4 | 0000000 | 000000 |