RFID Cards

Grant facility access to staff and authorized visitors with these cards. An alternative to ID badges with bar codes, they store and share loads of information without needing a line of sight to scan. Their high frequency lets them transfer data up to 4 in. away from an RFID reader/writer. Capable of both read and write functions, their memory can be repeatedly rewritten and reused. These cards’ memory is protected by its plastic body, unlike cards with printed bar codes, which can scuff, smudge, and wear out over time. They meet ISO and IEC standards for frequency ranges, and they’re CE marked to meet European health, safety, and environmental protection requirements. IP68 rated, they will still work in dusty or wet environments.

Temperature | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Memory Size, bytes | For Use On | Ht., mm | Wd., mm | Thick., mm | Min. | Max. | Environmental Rating | Material | Each | |

High Frequency (13.56 MHz) | ||||||||||

| 250 | Nonmetal | 54 | 86 | 0.8 | -10° F | 120° F @ 10 yrs. | IP68 | Plastic | 0000000 | 000000 |

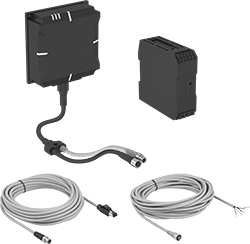

RFID Reader/Writer Kits

Scan and sort RFID-tagged inventory, track RFID-tagged items around your facility, and control building access. Unlike bar code scanners, these readers/writers can scan multiple tags simultaneously without direct line of sight. Plug in the included power supply, and connect them directly to your host system, such as a PC or programmable logic controller (PLC). As tagged items pass by, these readers/writers quickly read and transmit data to your system or write new information to the tags.

Configure your reader/writer settings and access tag data through a web browser interface. Reader/writers have color LEDs built in to indicate each successful scan. Choose a reader/writer that is compatible with the frequency of your RFID tags, cards, and labels (not included). Reader/writers meet ISO and IEC standards for frequency ranges.

High-frequency reader/writers are good for short-range scanning. They’re often used to sort or track items on a conveyor belt and to scan ID cards for facility access. Sensing distance for your reader/writers is reduced when tags are smaller, misaligned, not optimized for their mounting material, or scanned in hot or cold environments. The sensing distances in the table below represent typical factory conditions for a 26 × 100 mm tag optimized for its mounting material.

Sensing Distance | Mounting | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Communication Protocol | Ethernet Connection Type | On Nonmetal | On Metal | Ht. | Wd. | Dp. | Temp. Range, °F | Environmental Rating | No. of Holes | Screw Size | Includes | Each | |

High Frequency (13.56 MHz) | |||||||||||||

| Ethernet/IP | RJ45 | 1 1/2" | 1" | 2" | 2" | 1 1/4" | 15° to 130° | IP67 | 2 | M4 | One Reader/Writer One 32-ft. Lg. Communication Cord One 32-ft. Lg. Power Supply Cord One 24V DC Power Supply | 0000000 | 000000000 |

| Modbus TCP/IP | RJ45 | 1 1/2" | 1" | 2" | 2" | 1 1/4" | 15° to 130° | IP67 | 2 | M4 | One Reader/Writer One 32-ft. Lg. Communication/Power Supply Cord One 24V DC Power Supply | 0000000 | 00000000 |

| Profinet | RJ45 | 1 1/2" | 1" | 2" | 2" | 1 1/4" | 15° to 130° | IP67 | 2 | M4 | One Reader/Writer One 32-ft. Lg. Communication Cord One 32-ft. Lg. Power Supply Cord One 24V DC Power Supply | 0000000 | 00000000 |