About Installing Blind Rivets

More

Aluminum Flush-Mount Blind Rivets

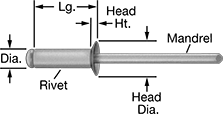

Lightweight and corrosion resistant, these blind rivets are made of aluminum. Install them in countersunk holes, and their angled head sits flush with the material’s surface.

They're often used to fasten material together when you only have access to one side, such as when attaching hinges and shelves. You can also use them to join materials that are difficult to weld or solder. The back of the rivet deforms during installation, creating a permanent hold that resists vibration without the chance of overtightening and stripping.

To install these rivets, you’ll need a blind rivet tool (sold separately). Be sure to pick a tool that’s compatible with your rivet’s diameter and material. For more information on installing rivets, see About Installing Blind Rivets.

Blind rivets that meet ISO 15978 (formerly DIN 7337) comply with international dimensional standards for blind rivets.

For technical drawings and 3-D models, click on a part number.

| For Material Thick., mm | Lg., mm | For Hole Size, mm | Head Dia., mm | Head Ht., mm | Countersink Angle | Shear Strength, lbs. | Tensile Strength, lbs. | Specifications Met | Pkg. Qty. | Pkg. | |

3 mm Dia. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.5-3.5 | 6 | 3-3.1 | 6 | 0.9 | 120° | 110 | 80 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 3.5-5.5 | 8 | 3-3.1 | 6 | 0.9 | 120° | 110 | 80 | DIN 7337, ISO 15978 | 100 | 000000000 | 00000 |

| 5.5-7 | 10 | 3-3.1 | 6 | 0.9 | 120° | 110 | 80 | DIN 7337, ISO 15978 | 100 | 000000000 | 00000 |

| 7-9 | 12 | 3-3.1 | 6 | 0.9 | 120° | 110 | 80 | DIN 7337, ISO 15978 | 25 | 000000000 | 0000 |

| 9-13 | 16 | 3-3.1 | 6 | 0.9 | 120° | 110 | 80 | DIN 7337, ISO 15978 | 25 | 000000000 | 0000 |

4 mm Dia. | |||||||||||

| 1.5-3 | 6 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 50 | 000000000 | 0000 |

| 3-5 | 8 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 5-6.5 | 10 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 6.5-8.5 | 12 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 50 | 000000000 | 0000 |

| 8.5-12.5 | 16 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

| 12.5-14.5 | 18 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 25 | 000000000 | 0000 |

| 12.5-16.5 | 20 | 4-4.1 | 7.5 | 1 | 120° | 170 | 170 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

5 mm Dia. | |||||||||||

| 3-4.5 | 8 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 4.5-6 | 10 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 6-8 | 12 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 8-12 | 16 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 50 | 000000000 | 00000 |

| 10-14 | 18 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

| 12-16 | 20 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

| 16-21 | 25 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

| 21-25 | 30 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 25 | 000000000 | 00000 |

| 25-30 | 35 | 5-5.1 | 9 | 1.2 | 120° | 350 | 290 | DIN 7337, ISO 15978 | 5 | 000000000 | 00000 |