Filter by

For Robot Arm Manufacturer

Equipment Coverage

Export Control Classification Number (ECCN)

Robot Cell Component

Performance

DFARS Specialty Metals

Switch Padding Component

Electrical Connection

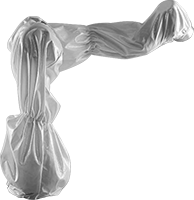

Paint-Absorbing Robot Arm Covers

|  |  |

Covers Full Robot Arm | Lower Arm | Upper Arm |

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Robot Arm Mfr. (Series/Model No.) | Color | Material | 1-4 | 5-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Covers Full Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA) | White | Polyester Fabric | 00000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA/L, 20iA/L) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 25iA, 30iA) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (LR Mate 200iD/7L) | White | Polyester Fabric | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR3, UR3e) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR5, UR5e) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR10, UR10e) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR20) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR30) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Covers Lower Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (LR Mate 200iD/7L) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Covers Upper Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (LR Mate 200iD/7L) | White | Polyester Fabric | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Liquid-Resistant Robot Arm Covers

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Robot Arm Mfr. (Series/Model No.) | Color | Temp. Range, ° F | Material | 1-4 | 5-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Covers Full Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA/L, 20iA/L) | White | -65 to 190 | Plastic-Laminated Polyester Fabric | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 25iA, 30iA) | White | -65 to 190 | Plastic-Laminated Polyester Fabric | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR5, UR5e) | Yellow | -65 to 190 | Plastic-Laminated Polyester Fabric | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR10, UR10e) | Yellow | -65 to 190 | Plastic-Laminated Polyester Fabric | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR20) | White | -65 to 190 | Plastic-Laminated Polyester Fabric | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant Robot Arm Covers

For Robot Arm Mfr. (Series/Model No.) | Color | Temp. Range, ° F | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Covers Full Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 5iA) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA/L) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 20iA/L) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 25iA) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 30iA) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR3e) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR5e) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR10e) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR16e) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR20) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR30) | White | -20 to 212 | Polyurethane-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Abrasion-Resistant Robot Arm Covers

For Robot Arm Mfr. (Series/Model No.) | Color | Temp. Range, ° F | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Covers Full Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 5iA) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA/L) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 20iA/L) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 25iA) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 30iA) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR3e) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR5e) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR10e) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR16e) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR20) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR30) | Gray | 32 to 140 | Plastic-Laminated Polyester Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat- and Weld-Spatter-Resistant Robot Arm Covers

For Robot Arm Mfr. (Series/Model No.) | Color | Temp. Range, ° F | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Covers Full Robot Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 5iA) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 10iA/L) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 20iA/L) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 25iA) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FANUC (CRX 30iA) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR3e) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR5e) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR10e) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR16e) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR20) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Universal Robots (UR30) | Silver | -235 to 1,220 | Aluminum-Coated Aramid/Carbon Fiber Fabric | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

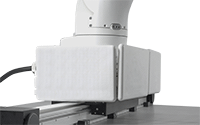

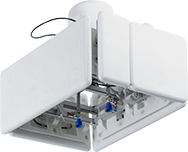

Contact-Sensing Switch Padding

|  |

Padding Installed on a Positioning Slide | Padding Installed on a Vacuum Lifter |

Padding

Lg., mm | Wd., mm | Thk., mm | Sensor Response Time, ms | Mounting Fasteners Included | Temp. Range, ° F | Enclosure Rating | Material | Includes | Specs. Met | Certification | Flammability Rating | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 200 | 18.5 | 9 | No | 40 to 100 | IP50 | Polyurethane Foam | One 4 m Lg. Padding-to-Padding Cable | ISO/TS 15066, ISO 13849-1, IEC 62061 | TUV Rheinland Certified, C-TUV Rheinland Certified, CE Marked | UL 94 V-2 | 00000000 | 0000000 | |

| 300 | 200 | 20.5 | 9 | No | 40 to 100 | IP50 | Polyurethane Foam | One 4 m Lg. Padding-to-Padding Cable | ISO/TS 15066, ISO 13849-1, IEC 62061 | TUV Rheinland Certified, C-TUV Rheinland Certified, CE Marked | UL 94 V-2 | 00000000 | 000000 | |

| 400 | 200 | 20 | 9 | No | 40 to 100 | IP50 | Polyurethane Foam | One 4 m Lg. Padding-to-Padding Cable | ISO/TS 15066, ISO 13849-1, IEC 62061 | TUV Rheinland Certified, C-TUV Rheinland Certified, CE Marked | UL 94 V-2 | 00000000 | 000000 |

Controllers

Input | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Voltage, V DC | Electrical Connection | Lg., mm | Wd., mm | Ht., mm | Enclosure Rating | Housing Material | Includes | Certification | Each | ||

| 24 | Terminal Block | 97 | 64 | 37.8 | IP50 | Plastic | One 5 m Lg. Controller-to-Padding Cord, One 5 m Lg. Control Box-to-Safety Circuit Cord | TUV Rheinland Certified, C-TUV Rheinland Certified, CE Marked | 00000000 | 0000000 | |