About Sleeving

More

High-Strength Expandable Sleeving

With excellent torsional strength, this sleeving withstands the extreme twisting found in robotics. Made of carbon fiber, it has impact strength similar to steel yet is lighter than plastic and rubber. Resistant to corrosion and chemicals, it’s often used to protect brake lines and hydraulic lines. It’s expandable, so it stretches to fit over items for easy installation, then tightens around its contents for a secure fit. The braided construction permits heat and moisture to dissipate. Cut with scissors or a hot-blade knife.

Wrap-Around Sleeving for Cable and Hose Carriers

Often used in robotics and other automated applications, this sleeving adds an extra layer of protection and insulation to cable and hose carriers. It’s highly flexible and withstands continuous motion without tearing or fraying. It opens along its entire length, so there’s no need to disconnect lines or use tools for maintenance such as adding or removing cable.

PVC fabric sleeving has a chemical-resistant polyester coating, so it’s commonly used to protect wire in areas where painting or sealing takes place. A hook-and-loop closure allows access for maintenance at any point. Elastic on both ends holds sleeving in place.

Leather sleeving has excellent abrasion resistance, making it a good choice for applications where sleeving will make contact with other objects. For easy maintenance, a zipper closure lets you access the sleeving at all points. Hook-and-loop closures at either end of the sleeving secure it in place.

Kevlar aramid sleeving resists temperatures up to 1000° F. Use it to protect wire near furnaces, in welding areas, and in other extremely hot environments. This sleeving has good abrasion resistance, a zipper closure for easy maintenance, and hook-and-loop straps on each end to hold sleeving in place.

Temperature Range, °F | 3 ft. Lg. | 6 1/2 ft. Lg. | |||||

|---|---|---|---|---|---|---|---|

| For Carrier OD | Min. | Max. | Color | Each | Each | ||

| 1.69" / 43 mm | -20° | 100° | White | 00000000 | 000000 | 00000000 | 0000000 |

| 2.13" / 54 mm | -20° | 100° | White | 00000000 | 00000 | 00000000 | 000000 |

| 2.56" / 65 mm | -20° | 100° | White | 00000000 | 000000 | 00000000 | 000000 |

| 2.76" / 70.2 mm | -20° | 100° | White | 00000000 | 00000 | 00000000 | 000000 |

| 3.19" / 81 mm | -20° | 100° | White | 00000000 | 000000 | 0000000 | 000000 |

| 3.72" / 94.5 mm | -20° | 100° | White | 00000000 | 000000 | 00000000 | 000000 |

| 4.5" / 108 mm | -20° | 100° | White | 00000000 | 000000 | 00000000 | 000000 |

| 5.31" / 135 mm | -20° | 100° | White | 00000000 | 000000 | 00000000 | 000000 |

Temperature Range, °F | 3 ft. Lg. | 6 1/2 ft. Lg. | |||||

|---|---|---|---|---|---|---|---|

| For Carrier OD | Min. | Max. | Color | Each | Each | ||

| 1.69" / 43 mm | -40° | 212° | Black | 00000000 | 0000000 | 00000000 | 0000000 |

| 2.13" / 54 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

| 2.56" / 65 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

| 2.76" / 70.2 mm | -40° | 212° | Black | 00000000 | 000000 | 0000000 | 000000 |

| 3.19" / 81 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

| 3.72" / 94.5 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

| 4.5" / 108 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

| 5.31" / 135 mm | -40° | 212° | Black | 00000000 | 000000 | 00000000 | 000000 |

3 ft. Lg. | 6 1/2 ft. Lg. | |||||

|---|---|---|---|---|---|---|

| For Carrier OD | Max. Temperature, °F | Color | Each | Each | ||

| 1.69" / 43 mm | 1000° | White | 00000000 | 0000000 | 00000000 | 0000000 |

| 2.13" / 54 mm | 1000° | White | 00000000 | 000000 | 0000000 | 000000 |

| 2.56" / 65 mm | 1000° | White | 00000000 | 000000 | 00000000 | 000000 |

| 2.76" / 70.2 mm | 1000° | White | 00000000 | 000000 | 00000000 | 000000 |

| 3.19" / 81 mm | 1000° | White | 00000000 | 000000 | 00000000 | 000000 |

| 3.72" / 94.5 mm | 1000° | White | 00000000 | 000000 | 00000000 | 000000 |

| 4.5" / 108 mm | 1000° | White | 00000000 | 000000 | 0000000 | 000000 |

| 5.31" / 135 mm | 1000° | White | 00000000 | 000000 | 00000000 | 000000 |

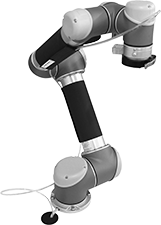

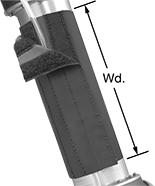

Hook-and-Loop Wrap-Around Sleeving for Universal Robots

Organize and protect the cables and tubing on your Universal Robots arm without hindering its movement. This sleeving is made for Universal Robots arms, so you don’t need to measure, cut, or customize for a good fit. The hook-and-loop closure makes installation quick, and unlike cable ties, it’s easy to detach and adjust. Cables run through a separate channel, so you can access them without removing the sleeving from your arm. Made from polyurethane, this sleeving is flexible enough for cables and tubing to move easily, and durable enough to withstand continuous movement. It’s also lighter than hose carriers and conduit, so it won’t weigh down your robot arm. Each includes two pieces of sleeving.

| ID | Wd. | Lg. | Wall Thick. | Temperature Range, °F | Features | Cable Opening Wd. | Color | Each | |

Polyurethane Rubber | |||||||||

|---|---|---|---|---|---|---|---|---|---|

For UR3 and UR3e Series Robot Arms | |||||||||

| 2 1/8" 2 5/8" | 3 1/4" 3 1/4" | 10 7/8" 12 3/8" | 0.018" | -60° to 200° | Cable Channel | 1" | Black | 00000000 | 0000000 |

For UR5 and UR5e Series Robot Arms | |||||||||

| 3" 3 3/8" | 8" 8" | 13 1/2" 14 3/4" | 0.018" | -60° to 200° | Cable Channel | 1" | Black | 00000000 | 000000 |

For UR10 and UR10e Series Robot Arms | |||||||||

| 3 3/8" 4 1/4" | 14" 14" | 14 7/8" 17 3/4" | 0.018" | -60° to 200° | Cable Channel | 1" | Black | 00000000 | 000000 |

Interference-Shielding Wrap-Around Sleeving

Use this shielded sleeving to protect wire and cable from signal distortion caused by nearby equipment and devices. A sewn-in ground wire dissipates any stored charge. It provides good protection against abrasion. Wrap it around wire and cable without disconnecting them; sleeving has a slit along the entire length. Sleeving with an adhesive strip closure is permanently sealed when the adhesive is applied.Sleeving with conductive cloth shielding can withstand continuous motion without tearing or fraying. It’s often used to protect wire, cable, and hose in robotics and other automated applications.

Polyurethane rubber sleeving provides excellent resistance to solvents, oil, and grease.

Per Ft. | |||||||

|---|---|---|---|---|---|---|---|

| ID | Wall Thick. | Temperature Range, °F | Color | Lengths, ft. | 1-24 | 25-Up | |

Polyurethane Rubber with Conductive Cloth Shielding | |||||||

| 3/8" | 1/32" | -45° to 220° | Black | 0000000 | 000000 | 000000 | |

| 1/2" | 1/32" | -45° to 220° | Black | 0000000 | 00000 | 00000 | |

| 1" | 1/32" | -45° to 220° | Black | 0000000 | 00000 | 00000 | |

| 1 1/2" | 1/32" | -45° to 220° | Black | 0000000 | 00000 | 00000 | |

| 2" | 1/32" | -45° to 220° | Black | 0000000 | 00000 | 00000 | |