Robot-Ready Electric Vacuum Lifters

Attach these lifters to FANUC CRX or Universal Robots collaborative robots. They handle items up to 3.5 times heavier than our lifters for lightweight items. Because they use electricity to pick up and move items with suction, there’s no need for compressed air or air control valves. They don’t have pinch points or sharp edges, so they help you meet ISO/TS 15066 international safety standards for people working near robots.

Often used in packaging, palletizing, and material handling, these lifters can grip everything from cardboard boxes to bags of screws. With soft rubber cups, they’re less likely than pick-and-place grippers to damage glass, thin plastic, and other delicate objects. To install, plug the cord into your robot arm. It carries both power and control signals.

These lifters include a robot tool mount, vacuum generator, quick-change cup mount, vacuum cup assembly, extra vacuum cup, and cord. Use the quick-change cup mount to swap in other vacuum cup assemblies (sold separately).

Once installed, use your robot program to turn suction on or off. An integrated vacuum switch tells your robot when an item is picked up, so it can move to the next location. View and adjust vacuum levels and other settings with an onboard screen and keypad.

Lifters for FANUC CRX arms are FANUC approved and lifters for Universal Robots (UR) arms are UR+ certified, so they’ve been tested to work seamlessly with your robot. For simple integration with your teach pendant software, download FANUC and URCap plug-ins from the manufacturer’s website.

Maximum weight capacity is achieved only when lifting items with smooth, nonporous surfaces, such as those made from glass and sheet metal. Materials like cardboard leak air when lifted, which reduces your lifter’s capacity. For instance, you can lift about 25% of the maximum capacity when using these lifters on a cardboard box similar to those we ship our parts in.

Weight Capacity | O'all | Flat Cup | Single-Bellows Cup | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Max. | Reduced | Dia., mm | Ht., mm | Mounting Fasteners Included | Dia., mm | Ht., mm | Dia., mm | Ht., mm | Each | |

Schmalz ECBPi Series | |||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA, 30iA) | 22 lbs. | 6 lbs. | 151.5 | 188.8 | Yes | 42 | 15 | 42 | 30 | 0000000 | 000000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR7e; UR10; UR10e; UR12e; UR15; UR16e) | 22 lbs. | 6 lbs. | 151.5 | 188.8 | Yes | 42 | 15 | 42 | 30 | 0000000 | 00000000 |

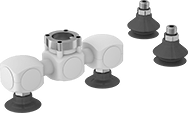

Cup assemblies connect directly to the quick-change cup mount on these lifters. Assemblies with more cups have better stability when gripping items with large surface areas or uneven weight distribution.

All assemblies include flat and single-bellows cups. Flat cups work well with flat surfaces, such as the sides of boxes. Single-bellows cups firmly hold uneven material. Swap out worn or damaged cups with replacement vacuum cups.

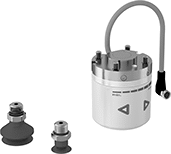

Robot-Ready Electric Vacuum Lifters for Lightweight Items

Made for FANUC CRX and Universal Robots collaborative robots, these lifters use suction to pick up and move lightweight items, up to 6 lbs. They run on electricity, so you don’t need compressed air or air valves. Often used in packaging, palletizing, and material handling, these lifters can grip everything from small cardboard boxes to bagged screws. With soft rubber cups, they’re less likely than pick-and-place grippers to damage glass, thin plastic, and other delicate materials. They’re also simple to set up—a single cord supplies both power and control to your robot arm. They help you meet ISO/TS 15066 international safety standards for people working near robots because there are no pinch points or sharp edges.

These lifters include a vacuum generator with a robot mount, a cord, and two types of vacuum cups. Use the flat cup for items with level surfaces and the single-bellows cup for gripping tilted items or items of different heights. You can also use your own vacuum cup if it has a compatible 1/4 BSPP threaded connection. For large items, items that might break if lifted from a single point, or material with uneven weight distribution, use 2-, 3-, or 4-cup assemblies (sold separately).

Once you’ve installed these lifters, use your robot program to turn suction on or off. An integrated vacuum switch tells your robot when an item is picked up, so it knows when to move to the next location. Adjust the vacuum level using the arrow keys on the lifter body. These lifters achieve maximum weight capacity only when handling items with smooth, nonporous surfaces, such as glass or sheet metal.

Lifters for FANUC CRX arms are FANUC approved and lifters for Universal Robots (UR) arms are UR+ certified, so they’ve been tested to work seamlessly with your robot. For simple integration with your teach pendant software, download FANUC and URCap plug-ins from the manufacturer’s website.

O'all | Flat Cup | Single-Bellows Cup | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Max. Weight Capacity | Dia., mm | Ht., mm | Mounting Fasteners Included | Dia., mm | Ht., mm | Dia., mm | Ht., mm | Each | |

Schmalz ECBPMi Series | ||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA, 30iA) | 6 lbs. | 63 | 112.4 | Yes | 20 | 12.8 | 32 | 23 | 0000000 | 000000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR7e) | 6 lbs. | 63 | 112.4 | Yes | 20 | 12.8 | 32 | 23 | 0000000 | 00000000 |

| Universal Robots (UR10; UR10e; UR12e; UR15; UR16e) | 6 lbs. | 63 | 112.4 | Yes | 20 | 12.8 | 32 | 23 | 0000000 | 00000000 |

Cup assemblies attach directly to the bottom of vacuum lifters. Swap out your single cup for multiple cups for more stability—they spread suction across larger areas. Use them to pick up thin glass, plastic sheets, and other items that might flex or break when lifted from a single point.

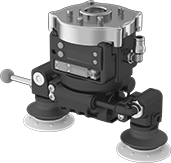

Robot-Ready Vacuum Lifters

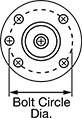

With robot tool mounts and connectors, these vacuum lifters come ready to attach to robot arms with standard ISO mounting hole patterns. Use them with compressed air to grip, lift, and move items with curves, angles, and varied heights. Also known as venturi devices, they generate suction without an installed vacuum system. If you don't see your robot model number listed, measure the bolt circle diameter to determine mounting compatibility.

Lifters and lifters with cups have two arms with vacuum cup connections. You can adjust the width of the arms to handle large items as well as tilt them to better grip uneven shapes. You can even remove an arm for applications that require only one cup. All of these lifters have a digital display for viewing the status of the lifter and controlling the vacuum. They’re protected from dust and water splashes. Lifters don’t include cups. Add vacuum cups that meet your specific needs. Lifters with cups include eight silicone and polyurethane rubber cups with different sizes and number of bellows. Cups with more bellows are better for handling items that have more variations in shape.

Lifters with a foam pad have an EPDM foam pad that’s soft enough to conform to items without damaging them. They’re best for delicate surfaces as well as porous surfaces where cups cannot obtain an airtight grip. They are not protected from dust and water splashes. Those with a sensor communicate the grip position of your lifter to a controller. They have LED status indicators, so you can quickly see the status of the lifters.

Lifters with PNP signal output communicate proximity with a positive signal, while those with NPN signal output send a negative signal.

UR+ certified lifters have been tested and approved to work seamlessly with Universal Robots (UR) arms. Plug the included software directly into your teach pendant to program the lifter.

Choose lifters with an additional port if you’d like to add a pressure transmitter (not included). Your transmitter will convert air pressure to an electrical signal for viewing air measurements on remote displays and programmable logic controllers (PLCs).

Optional sensors can be added to lifters with a foam pad for communicating the grip position to a controller. They require an A-code micro M12 power cord (sold separately).

Warning: Never use to lift people or items over people.

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 63.5 mm (ISO 63) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces—Polyurethane and Silicone Rubber Cups | |||||||||||

With Additional Port | |||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 31.5 mm (ISO 31.5) | No | NPN, PNP | 00000000 | 000000000 |

| ABB (IRB 1520ID) Yaskawa/Motoman (HC 10T; SIA 10D, 10F) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 63.5 mm (ISO 63) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 15.4 lbs. @ 24 in. of Hg | 24 in. of Hg | 1 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 40 mm (ISO 40) | No | NPN, PNP | 00000000 | 00000000 |

Female Air Connection | End of Robot Arm | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model Number) | Pad Ht., mm | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Each | |

For Smooth and Textured Surfaces—EPDM Foam Pad | ||||||||||||

With Additional Port | ||||||||||||

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 000000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 00000000 |

| ABB (IRB 120; IRB 1200) FANUC (CR 4iA, 7iA; LR Mate 7L) KUKA Robotics (KR 10 R1100-2) Precise Automation (PAVP6; PF3400) Yaskawa/Motoman (GP 7, 8; MH 3BM, 3F, 5LS II, 5S II; MPP 3H, 3S) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 31.5 mm (ISO 31.5) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 2400; IRB 2600) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) Omron (TM 5, 12, 14) Productive Robotics (OB7) Staubli (TX2) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

| ABB (IRB 360 6/1600, 8/1130; IRB 140; IRB 1410; IRB 1600) FANUC (M-20 iA) Precise Automation (PP100) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 40 mm (ISO 40) | No | __ | 00000000 | 00000000 |

With Sensor | ||||||||||||

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 10 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 20 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR10; UR10e; UR16; UR16e) | 30 | 48.8 lbs. @ 24 in. of Hg | 26 in. of Hg | 4 scfm @ 60 psi | Bagged Material, Cardboard, Electronics, Glass, Plastic, Sheet Metal | 1/8 | BSPP | 50 mm (ISO 50) | No | NPN, PNP | 00000000 | 00000000 |

| Output Voltage | Connection Type | Gender | Housing Thread Size | Number of Poles | Each | |

| 1-5V DC | Nano M8 | Male | M8 | 8 | 00000000 | 0000000 |

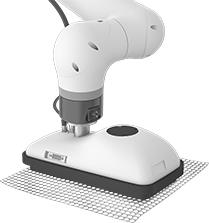

Robot-Ready Vacuum Lifters for Large Surfaces

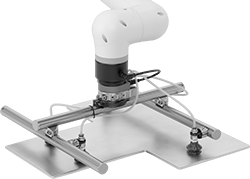

These large-surface lifters come with software, robot tool mounts, and connectors for quick setup and use with FANUC CRX robot arms. Using compressed air through multiple suction ports, they lift larger and heavier items than standard vacuum lifters. Also known as venturi devices, they generate suction without an installed vacuum system. To view data and adjust settings in a smartphone app, hold a phone that can read near-field communication (NFC) up to one of the NFC tags on these lifters. A digital display lets you read measurements while standing next to them.

These lifters have an IP40 rating, meaning that they keep out objects 1 mm or larger—such as wire—to protect their inner parts. They also meet ISO/TS 15066—with no pinch points or sharp edges, you can safely use them on robots that will be near people.

Lifters with cups grip irregularly shaped items better than lifters with a pad.

Lifters with a pad are better at lifting porous items than lifters with cups, and are also less likely to damage delicate surfaces.

Warning: Never use to lift people or items over people.

Female Air Connection | End of Robot Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Communication Standard | Specifications Met | Each | |

For Smooth and Textured Surfaces—Silicone Rubber Cups | |||||||||||||

Schmalz FXCB Series | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 18 lbs. @ 17.7 in. of Hg | 17.7 in. of Hg | 7.7 scfm @ 80 psi | Bagged Material, Cardboard, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | Yes | PNP | IO Link, NFC | ISO/TS 15066 | 0000000 | 000000000 |

Female Air Connection | End of Robot Arm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Cap. @ Vacuum | Max. Vacuum | Air Consumption @ Pressure | For Use With | Pipe Size | Thread Type | Bolt Circle Dia. (Mount. Hole Pattern Compatibility) | Mount. Fasteners Included | Signal Output Type | Communication Standard | Specifications Met | Each | |

For Smooth and Textured Surfaces—EPDM Foam Pad | |||||||||||||

Schmalz FXCB Series | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA) | 18 lbs. @ 17.7 in. of Hg | 17.7 in. of Hg | 7.7 scfm @ 80 psi | Bagged Material, Cardboard, Glass, Plastic, Sheet Metal | 1/4 | BSPP | 50 mm (ISO 50) | Yes | PNP | IO Link, NFC | ISO/TS 15066 | 0000000 | 000000000 |

| Number of Bellows | Cup Dia., mm | Compressed Cup Ht., mm | Cup Ht., mm | Mount. Hole Dia., mm | Each | |

Silicone Rubber | ||||||

|---|---|---|---|---|---|---|

| 2 | 43.5 | 27 | 47 | 4.6 | 00000000 | 000000 |

Number of | |||||

|---|---|---|---|---|---|

| Columns | Rows | Lg., mm | Wd., mm | Each | |

EPDM Foam | |||||

| 15 | 3 | 300 | 130 | 00000000 | 0000000 |

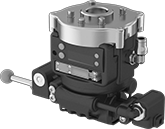

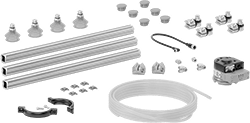

Robot-Ready Configurable Vacuum Lifters

Everything you need to build a custom vacuum lifter for your collaborative robot—including rails, connecting hardware, vacuum cups, air hose, robot arm mount, and vacuum generator, also called a venturi device. Whether you’re picking and placing stamped sheet metal, molded plastic, or cardboard boxes, this system gives you the freedom to position vacuum cups where you need them. Go from concept to ready-to-lift in minutes—you’ll need only simple tools for assembly. Build a custom frame with the aluminum rails—you can cut them down to size and join them together with the included connectors. Place the vacuum cups anywhere along your frame.

Hooking these lifters up to your robot arm is simple too. Use the included mount to bolt them right to the end of your robot arm. All that’s left is to plug the power cord into your robot arm and hook the lifter up to your compressed air line.

These lifters have integrated air control valves, so you can use your robot’s control program to turn suction on or off via digital inputs and outputs. A built-in vacuum switch tells your robot when an item is picked up, so it knows to move to the next location.

Lifters for Universal Robots (UR) arms are UR+ certified, so they’ve been tested to work seamlessly with your robot. For simple integration with your teach pendant software, download the URCap plug-in from the manufacturer’s website.

Maximum weight capacity is achieved only when lifting items with smooth, nonporous surfaces, such as glass and sheet metal. Materials like cardboard leak air when lifted, which reduces your lifter’s capacity. For instance, you can lift about 20% of the maximum capacity when using these lifters on a cardboard box similar to those we ship our parts in.

Weight Capacity | Single-Bellows Cup | Lifter | Air Inlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Max. | Reduced | No. of Cups | Dia., mm | Ht., mm | Air Consumption @ Pressure | Ht., mm | Wd., mm | Dp., mm | Pipe Size | Thread Type | Each | |

Schmalz PXT, RECBi Series | |||||||||||||

| FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA, 30iA) | 112 lbs. | 24 lbs. | 4 | 41 | 37.2 | 3.1 scfm @ 80 psi | 68 | 108 | 75 | 1/8 | BSPP | 00000000 | 000000000 |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR7e; UR10; UR10e; UR12e; UR15; UR16e) | 112 lbs. | 24 lbs. | 4 | 41 | 37.2 | 3.1 scfm @ 80 psi | 68 | 108 | 75 | 1/8 | BSPP | 00000000 | 00000000 |