Robot-Ready Electric Grippers

Gripper Fingers and

Robot Arm (Not Included)

Including a robot tool mount and electrical connectors, these grippers come ready to attach to robot arms with standard ISO mounting hole patterns. Good for areas without compressed air, they use electricity to pick and place items in packaging, assembly, and machine-tending applications. All have a servomotor that opens and closes the grippers with equal force to grasp and release items from the inside or outside. Install the included software directly into your controller or teach pendant to program your gripper.

Select grippers that match your arm’s manufacturer series and model number or that are compatible with your electrical connection and signal output. Grippers with PNP signal output communicate proximity with a positive signal, while those with NPN signal output send a negative signal.

Warning: Never use to lift people or items over people.

Discrete I/O grippers have four set gripping forces to move items—use a screwdriver to select the force you’ll need. Since these grippers open and close at the same force and stroke with every cycle, they’re good for picking items of a similar size and material. A discrete I/O signal and included inductive proximity sensor send information about an item’s location to your robot arm. All of these grippers are suitable for use in clean rooms rated to ISO Class 5. They’re also rated IP30 to prevent objects greater than 2.5 mm, such as a screwdriver, from making contact with live circuits.

ISO/TS 15066 grippers help you meet international safety standards. They don’t have pinch points or sharp edges, so you can use them on robots that will be near people.

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | External / Internal Gripping Force | Max. Gripping Cap. | Cycles per Sec. | Stroke Wd., mm | Max. Finger Spacing, mm | Max. Holding Lg., mm | Wt. | Mounting Hole Pattern Compatibility | Lg., mm | Wd., mm | Dp., mm | Manufacturer (Series/Model No.) | Each | |

ISO/TS 15066 Nylon Plastic Housing and Steel Jaws | ||||||||||||||

PNP Signal Output and M8 Plug, 24V DC | ||||||||||||||

| Doosan (M0609, M0617, M1013, M1509) Omron (TM 5, 12, 14, 16, 20) | 7.5 lbs. 15 lbs. 22.5 lbs. 30 lbs. | 1.5 lbs. / 0.7 kg | 2 | 6 | 28 | 50 | 1.3 lbs. / 0.59 kg | ISO 50 | 118 | 93 | 90 | Schunk (Co-act EGP-C 40) | 0000000 | 000000000 |

Simply connect these fingers to your Schunk gripper and start moving items. Made of lightweight but also strong nylon, all have rubber gripping pads to protect items from damage.

Warning: Never use to lift people or items over people.

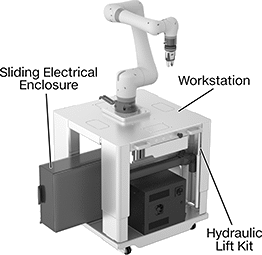

High-Capacity Robot Workstations

Support large robot arms and heavy payloads—these workstations can handle up to 1,800 pounds. With capacity to spare, add all the components and accessories you need for today’s job and tomorrow’s upgrades.

Optimize these workstations to fit your setup. To get them at the height you need, you can raise and lower the legs in 1" increments. They have swivel casters too, so you can steer them into the right spot. Then, extend the casters’ leveling pad to keep the workstation in place and compensate for uneven floors. Store your robot controller, teach pendant, and other accessories on the shelf below to keep them accessible but out of the way.

These workstations are compatible with many common robot arms—use the mounting holes on top and included fasteners to attach them. When used with large arms, such as the FANUC CRX-25iA or 30iA, these workstations must be anchored for stability and safety.

Capacity, lbs. | Overall | Robot Mount. Location | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Robot Arm Manufacturer (Series/Model No.) | Top | Overall | Ht. | Wd. | Dp. | Ht. Adjustment Increments | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Top Material | Frame Material | Wheel Configuration | Each | |

| Universal Robots (UR3; UR3e; UR5; UR5e; UR7e; UR10; UR10e; UR12e; UR16e) FANUC (CRX 5iA, 10iA, 10iA/L, 20iA/L, 25iA, 30iA; CR 4, 7, 7L) Doosan (M0609; M0617; M1013; M1509) Omron (TM 5, 12, 14) | 1,400 | 1,800 | 30"-38" | 40 1/4" | 36" | 1" | M6 (4) M8 (24) M10 (8) M12 (6) | Yes | Painted Steel | Painted Steel | Four Leveling Casters | 0000000 | 000000000 |

Adjust the height of your work surface with the push of a button—no need to do it by hand. However, with these kits installed, the top capacity of your workstation is reduced to 700 lbs.

Cylinder | Cylinder Mount. Holes | Pump Mount. Holes | Switch Mount. Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Material | No. of | Dia. | No. of | Dia. | No. of | Dia. | Mount. Fasteners Included | Cord Lg., ft. | Specifications Met | Each | |

| 1 1/2" | Aluminum | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 | UL Listed, CSA Certified | 00000000 | 000000000 |

Keep additional PLCs, safety relays, and other electrical components protected yet easy to access. They have a track that lets you smoothly slide them in and out. NEMA and IP rated, they protect against dust and water.

| Ht. | Wd. | Dp. | Environmental Rating | Mount. Hole Dia. (No. of Holes) | Mount. Fasteners Included | Material | Each | |

| 19 11/16" | 23 5/8" | 8 5/16" | IP66 NEMA 4 NEMA 12 | 6.6 mm (4) | Yes | Painted Steel | 0000000 | 000000000 |

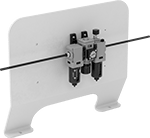

Attach these mounting plates to the bottom shelf to secure devices such as filters, regulators, and lubricators for your compressed air system.

Compressed Air Devices Mount. Location | Workstation Mount. Location | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Mount. Hole Thread Size (No. of Holes) | Mount. Fasteners Included | Mount. Hole Dia. (No. of Holes) | Mount. Fasteners Included | Material | Each | |

| 14 3/16" | 16 1/2" | 2" | M4 (4) M6 (2) | No | 6.6 mm (2) | Yes | Painted Steel | 0000000 | 0000000 |