Selecting Compatible Lead Screws and Nuts

More

Ball Screws and Nuts

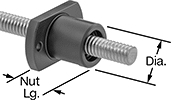

Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. Also known as single-start ball screws and nuts, they have a single thread that runs the length of the screw. They operate with more torque than fast-travel ball screws and nuts. To ensure compatibility, select components that have the same thread direction and size. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

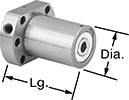

Root diameter indicates the diameter the ball screw will be after machining away the threads.

Ball Screw | Flange Ball Nut | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg., mm | Root Dia., mm | Tensile Strength, psi | Lg., mm | Dia., mm | Length Tolerance | No. of Thread Starts | Travel Distance per Turn, mm | Accuracy for Travel Distance per Turn | Hardness | Dynamic Thrust Load Capacity, lbs. | Max. Backlash, mm | Temp. Range, °F | Each | |

Carbon Steel Ball Screw with Alloy Steel Flange Ball Nut | |||||||||||||||

| M10 | 200 | 8.6 | 21,000 | 28 | 23 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 510 | 0.05 | 5° to 175° | 0000000 | 0000000 |

| M10 | 300 | 8.6 | 21,000 | 28 | 23 | Plus | 1 | 2 | ±0.210 mm per 300 mm | Rockwell C58 | 510 | 0.05 | 5° to 175° | 000000 | 000000 |

Fast-Travel Ball Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than ball screws with a single thread start. Internal ball bearings provide smooth low-friction travel in applications that require high speeds, accurate positioning, and repeatable movement. To ensure compatibility, select components that have the same thread size and number of thread starts. Ball nuts are furnished with a tube to keep ball bearings in place. Do not remove the tube until you are ready to install the nuts onto the screws.

Carbon steel ball screws and nuts are case hardened, so they resist wear better than standard carbon steel. However, they are less corrosion resistant than black-oxide alloy steel screws and nuts.

Travel distance per turn, also known as screw lead, is the distance a ball nut moves with one revolution of the ball screw.

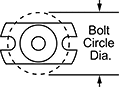

Flange | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | Dia. | Thick. | No. of Thread Starts | Travel Distance per Turn | Bolt Circle Dia. | Hardness | Dynamic Thrust Load Cap., lbs. | Max. Backlash | Temperature Range, °F | Each | ||

Carbon Steel | ||||||||||||||

| E | M12 | 43mm | 23mm | 40mm | 10mm | 2 | 10mm | 32mm | Rockwell C56 | 1,100 | 0.02mm | 32° to 150° | 00000000 | 0000000 |

Ball Splines and Bearings

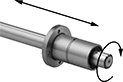

Create a compact linear and rotary motion system for applications requiring complex, fast movements, such as robotics. The grooves on the ball splines transmit rotary power as ball bearings move smoothly and precisely along their length, even at high speeds.

Ball splines are alloy steel for high strength and wear resistance. They're hardened on the outside for additional wear resistance while the center is soft enough to absorb stress from shifting loads. Those with a step-down end have a shoulder near the end to stop gears, sprockets, and bearings.

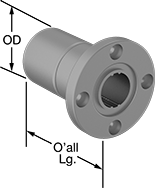

Bearings have a retaining ring groove, so they can be positioned in your system with a retaining ring (not included). Flanged bearings have a surface with mounting holes for attaching your load.

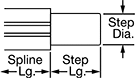

Spline | Step | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia., mm | Dia. Tolerance, mm | Lg., mm | Lg. Tolerance, mm | Lg., mm | No. of | Root Dia., mm | Dia., mm | Dia. Tolerance, mm | Lg., mm | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

Metric—52100 Alloy Steel | ||||||||||||||||

Splined End × Step-Down End | ||||||||||||||||

| 23 | -0.021 to 0 | 350 | -0.7874 to 0.7874 | 200 | 4 | 20.6 | 20 | -0.021 to 0 | 150 | 16 | Chamfered | Very Hard | Rockwell C60 | Case Hardened | 00000000 | 0000000 |

Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Spline Dia., mm | For No. of Splines | Overall Lg., mm | Flange OD, mm | OD, mm | Bearing | Ball | Dynamic Load Cap., lbs. | Max. Dynamic Torque, in.-lbs. | With Retaining Ring Grooves | Number of Mounting Holes | Each | |

| 23 | 4 | 70 | 60 | 37 | Steel | Steel | 2,750 | 1,433 | Yes | 4 | 00000000 | 0000000 |