About Shafts

More

Tight-Tolerance Multipurpose Oil-Hardening O1 Tool Steel Rods

- Yield Strength: 50,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Maximum Hardness After Heat Treatment: Rockwell C65

- Fabrication: Hot Rolled

- Specifications Met: ASTM A681

Ready for turning in a lathe, these rods are precision ground to a tight diameter tolerance. They’re also known as drill rod. Often used for dies, punches, and gauges, O1 tool steel is an oil-hardening material that resists wear and abrasion. It can also be surface hardened with heat treating for added wear resistance. These rods have been manufactured to meet ASTM A681 standards for performance and quality.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Linear Motion Shafts

Smooth, hard, and wear resistant, these shafts work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. Carbon steel shafts are good for general purpose use.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

| Lg., mm | Lg. Tolerance, mm | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Heat Treatment | Each | |

24 mm Dia. (Tolerance: -0.013 mm to 0 mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 200 | -0.5 to 0.5 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 500 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 00000 |

| 1,000 | -0.8 to 0.8 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

| 1,200 | -1.2 to 1.2 | 0.03 mm per 300 mm | 12 | Chamfered | Very Hard | Rockwell C59 | Case Hardened | 0000000 | 000000 |

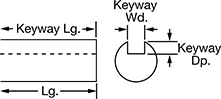

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. 1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Metric—1045 Carbon Steel | ||||||||||

24mm Dia. (Tolerance: -0.0635mm to 0mm) | ||||||||||

| 300mm | 300mm | 8mm | 4mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 500mm | 500mm | 8mm | 4mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 00000 |

| 1,000mm | 1,000mm | 8mm | 4mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,200mm | 1,200mm | 8mm | 4mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 1,800mm | 1,800mm | 8mm | 4mm | No | 0.33 mm per 300 mm | Chamfered | Medium | Rockwell B95 | 0000000 | 000000 |

Ultra-High-Temperature Quartz Glass Rods and Discs

- Color: Clear

- Max. Temperature: 2100° F

- Fabrication: Annealed

Able to withstand temperatures up to 2100° F, this quartz glass is useful in high-temperature applications that also require optical clarity, such as high-intensity lighting, fiber-optic production, and optical lens systems. It provides excellent UV transmission, as well as high transmission in the visible and infrared ranges.

12" Lg. | |||||

|---|---|---|---|---|---|

| Dia., mm | Dia. Tolerance, mm | Edge Fabrication | Lg. Tolerance | Each | |

| 24 | -0.380 to 0.380 | Ground | -0.125" to 0.125" | 00000000 | 000000 |