Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability.

Selecting Compatible Lead Screws and Nuts

More

About Shafts

More

Chrome-Plated Hardened Multipurpose 4140 Alloy Steel Rods

- Yield Strength: 100,000 psi

- Hardness: Rockwell C30 (Hard)

- Fabrication: Hot Rolled

A chrome plating on these rods increases their corrosion resistance. They're also hardened, which makes them more resistant to impacts and abrasion. Also known as chrome-moly steel, this versatile alloy steel is used for a wide range of parts, such as gears, axles, shafts, collets, and die holders. It resists fracturing from repeated stress.

Note: Rods may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

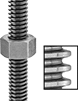

Metric Lead Screws and Nuts

Found in hand-powered clamps, vises, grates, doors, and work tables, lead screws and nuts have broad, square threads that are well suited for quick assembly, high clamping forces, and lifting and lowering heavy objects. To ensure compatibility, please select components that have the same thread direction, size, pitch, and number of thread starts. Class 7e and 7H components are compatible.

932 bearing bronze components are more wear resistant than brass components. They have good machinability and fair corrosion resistance.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

Flange nuts move objects along the length of a lead screw. They have a wide machinable flange for custom mounting.

Flange | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Ht., mm | Dia., mm | Dia., mm | Thick., mm | No. of Thread Starts | Speed Ratio | Travel Distance per Turn, mm | Thread Fit | Hardness | Each | |

932 Bearing Bronze | ||||||||||||

| M20 | 4 | 44 | 32 | 55 | 12 | 1 | 1:1 | 4 | 7H | Not Rated | 000000000 | 000000 |

Splined Rotary Shafts

Good for hydraulic systems, machine tools, and other high-torque applications, these shafts have teeth that transmit high rotational loads. Compared to keyed shafts, they last longer and handle higher torque. They’re also better than keyed shafts for applications requiring frequent disassembly or adjustments because you can move bushings along their splines.

Parallel splines have large, straight-sided teeth that resemble machine keys and transmit more torque than involute spline teeth. These splines are known as straight splines.

Bushings act as a surface to transmit rotary motion or to position a load along the length of the shaft. If welded into place, these bushings can act as a coupler, connecting two splined shafts.