Filter by

DFARS Specialty Metals

RoHS

Export Control Classification Number (ECCN)

REACH

Food Industry Standard

Rubber-Coated Conveyor Belt Pulleys

Straight

Keyway | 2" Diameter | ||||||||

|---|---|---|---|---|---|---|---|---|---|

Wd. | For Belt Wd. | Bore Dia. | Wd. | Ht. | Material | Coating Thk. | Each | ||

| 6" | 4" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K118 | 0000000 | |

| 6" | 4" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K119 | 000000 | |

| 8" | 6" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K158 | 000000 | |

| 8" | 6" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K159 | 000000 | |

| 10" | 8" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K198 | 000000 | |

| 10" | 8" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K199 | 000000 | |

| 12" | 10" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K248 | 000000 | |

| 12" | 10" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K249 | 000000 | |

| 14" | 12" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K288 | 000000 | |

| 14" | 12" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K289 | 000000 | |

| 16" | 14" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K338 | 000000 | |

| 16" | 14" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K339 | 000000 | |

| 18" | 16" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K378 | 000000 | |

| 18" | 16" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K379 | 000000 | |

| 20" | 18" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K137 | 000000 | |

| 20" | 18" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K138 | 000000 | |

| 22" | 20" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K177 | 000000 | |

| 22" | 20" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K178 | 000000 | |

| 26" | 24" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K227 | 000000 | |

| 26" | 24" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K228 | 000000 | |

| 32" | 30" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K267 | 000000 | |

| 32" | 30" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K268 | 000000 | |

| 38" | 36" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K317 | 000000 | |

| 38" | 36" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K318 | 000000 | |

Tapered

Keyway | 4" Diameter | 6" Diameter | 8" Diameter | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | For Belt Wd. | Bore Dia. | Wd. | Ht. | Material | Coating Thk. | Each | Each | Each | ||||

| 6" | 4" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K128 | 0000000 | ——— | 0 | ——— | 0 | |

| 6" | 4" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K129 | 000000 | 5706K419 | 0000000 | 5706K519 | 0000000 | |

| 8" | 6" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K168 | 000000 | ——— | 0 | ——— | 0 | |

| 8" | 6" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K169 | 000000 | 5706K429 | 000000 | 5706K529 | 000000 | |

| 10" | 8" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K218 | 000000 | ——— | 0 | ——— | 0 | |

| 10" | 8" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K219 | 000000 | 5706K439 | 000000 | 5706K539 | 000000 | |

| 12" | 10" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K258 | 000000 | ——— | 0 | ——— | 0 | |

| 12" | 10" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K259 | 000000 | 5706K449 | 000000 | 5706K549 | 000000 | |

| 14" | 12" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K298 | 000000 | ——— | 0 | ——— | 0 | |

| 14" | 12" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K299 | 000000 | 5706K459 | 000000 | 5706K559 | 000000 | |

| 16" | 14" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K348 | 000000 | ——— | 0 | ——— | 0 | |

| 16" | 14" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K349 | 000000 | 5706K615 | 000000 | 5706K569 | 000000 | |

| 18" | 16" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K388 | 000000 | ——— | 0 | ——— | 0 | |

| 18" | 16" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K389 | 000000 | 5706K479 | 000000 | 5706K579 | 000000 | |

| 20" | 18" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K147 | 000000 | ——— | 0 | ——— | 0 | |

| 20" | 18" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K148 | 000000 | 5706K619 | 000000 | 5706K718 | 000000 | |

| 22" | 20" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K187 | 000000 | ——— | 0 | ——— | 0 | |

| 22" | 20" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K188 | 000000 | 5706K628 | 000000 | 5706K728 | 000000 | |

| 26" | 24" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K237 | 000000 | ——— | 0 | ——— | 0 | |

| 26" | 24" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K238 | 000000 | 5706K638 | 000000 | 5706K738 | 000000 | |

| 32" | 30" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K277 | 000000 | ——— | 0 | ——— | 0 | |

| 32" | 30" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K278 | 000000 | 5706K648 | 000000 | 5706K748 | 000000 | |

| 38" | 36" | 3/4" | 3/16" | 3/32" | Rubber-Coated Steel | 1/4" | 5706K327 | 000000 | ——— | 0 | ——— | 0 | |

| 38" | 36" | 1" | 1/4" | 1/8" | Rubber-Coated Steel | 1/4" | 5706K328 | 000000 | 5706K658 | 000000 | 5706K758 | 000000 | |

Conveyor Roller Covers

Slide-On Covers

Conveyor Roller Covers | Nozzles | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Roller Dia. | Wd., ft. | Thk. | Hardness | Hardness Rating | Food Industry Std. | Pkg. Qty. | Pkg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyurethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K51 | 000000 | 5872K21 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/16" | Durometer 85A | Hard | — | 1 | 5872K102 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/8" | Durometer 70A | Hard | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 1 | 5872K106 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K53 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K55 | 00000 | 5872K23 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K57 | 00000 | 5872K24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K112 | 00000 | 5872K113 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Orange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K11 | 00000 | 5872K39 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K13 | 00000 | 5872K21 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/16" | Durometer 85A | Hard | — | 1 | 5872K101 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K15 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/4" | Durometer 85A | Hard | — | 1 | 5872K103 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K16 | 00000 | 5872K23 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K18 | 00000 | 5872K24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5 | 1/4" | Durometer 85A | Hard | — | 1 | 5872K107 | 000000 | 5872K24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K12 | 00000 | 5872K38 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K104 | 00000 | 5872K22 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 5 | 1/8" | Durometer 85A | Hard | — | 1 | 5872K108 | 00000 | 5872K24 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

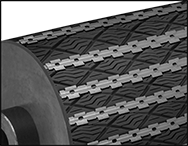

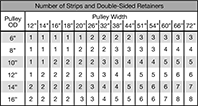

Conveyor Pulley Coatings

Straight Strips

| |

Straight Profile |

For Pulley Dia. | Lg. | Wd. | Thk. | Hardness | Hardness Rating | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SBR Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N11 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 72" | 5 1/2" | 9/16" | Durometer 60A | Soft | -50 to 225 | 3906N16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||