About Durometer

Durometer is the international standard for measuring the hardness of rubber, plastic, and most nonmetallic materials.

More

About Track Rollers

Also known as cam followers, track rollers have a thick outer roller that runs directly on a flat surface.

More

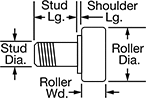

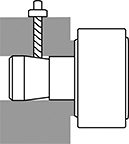

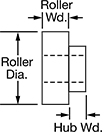

Threaded Track Rollers

Also known as cam followers, track rollers support loads while guiding and positioning work. Thread the stud directly into a component or secure with a nut for through-hole mounting.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Rollers with seal have end seals to protect rolling elements from dirt and contamination.

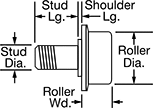

Roller, mm | Stud, mm | Thread | Shoulder, mm | Radial Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Dia. | Lg. | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Each | |

Black-Oxide Steel Flat Rollers without Seal | |||||||||||||||

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 6,300 | 3,500 | 2,400 | 250° | Needle Roller | 00000000 | 0000000 |

Black-Oxide Steel Flat Rollers with Seal | |||||||||||||||

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 6,300 | 3,500 | 2,400 | 250° | Needle Roller | 00000000 | 000000 |

Black-Oxide Steel Crowned Rollers without Seal | |||||||||||||||

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 4,200 | 6,400 | 3,800 | 250° | Needle Roller | 00000000 | 000000 |

Black-Oxide Steel Crowned Rollers with Seal | |||||||||||||||

| 35 | 18 | 16 | 32.5 | M16 | 1.5 | 18 | 24 | 0.8 | 4,200 | 6,400 | 3,800 | 250° | Needle Roller | 00000000 | 000000 |

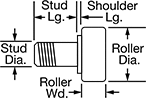

Maintenance-Free Threaded Track Rollers

Because they never need to be relubricated, these rollers are a good choice for hard-to-reach places. Also known as cam followers, track rollers support loads while guiding and positioning work. Thread the stud directly into a component or secure with a nut for through-hole mounting. Some rollers have end seals to block dirt and contamination.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Roller, mm | Stud, mm | Thread | Radial Load Cap., lbs. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Pitch, mm | Lg., mm | Shoulder Lg., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Includes | Each | |

Steel Crowned Rollers with Seal | |||||||||||||||

| 35 | 18 | 16 | 32 | M16 | 1.5 | 17 | 0.8 | 620 | 4,100 | 2,600 | 175° | Needle Roller | Mounting Hardware | 00000000 | 0000000 |

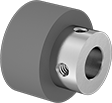

Shaft-Mount Track Rollers

Also known as yoke-style cam followers, these rollers have more mounting flexibility than threaded track rollers. They're typically mounted onto a shaft or clevis rod end. Lubricate rollers through a hole and groove in the inner ring.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Rollers with seal have end seals to protect rolling elements from dirt and contamination.

Roller, mm | Radial Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | For Shaft Dia., mm | Overall Wd., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | ID | ID Tolerance | Each | |

Black-Oxide Steel Crowned Rollers with Seal | ||||||||||||

| 35 | 18 | 15 | 19 | 3,600 | 3,200 | 2,100 | 210° | Needle Roller | 15mm | -0.008mm to 0mm | 0000000 | 000000 |

High-Load Shaft-Mount Track Rollers

With a double row of cylindrical roller bearings, these rollers provide the highest combination of speed and dynamic radial load ratings of any shaft-mount track roller we offer. Also known as yoke-style cam followers, these rollers have more mounting flexibility than threaded track rollers. They're typically mounted onto a shaft or clevis rod end.

Crowned rollers have a slight curve, which is invisible to the naked eye, to stay centered on surfaces that are not perfectly aligned and/or not perfectly flat.

Lubricate rollers without seal through a hole and groove in the inner ring.

Roller, mm | Radial Load Cap., lbs. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | For Shaft Dia., mm | Overall Wd., mm | Max. Speed, rpm | Static | Dynamic | Max. Temp., °F | Bearing Type | Each | |

Steel Flat Rollers without Seal | ||||||||||

| 35 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 0000000 |

Steel Crowned Rollers without Seal | ||||||||||

| 35 | 18 | 15 | 19 | 280 | 6,100 | 5,200 | 245° | Cylindrical Roller | 0000000 | 000000 |

Tapered Stud Track Rollers

Install these rollers in worn-out mounting holes or where you don’t have access to the back of the mounting hole. The stud is tapered, so you can quickly secure them in place with a set screw (not included) instead of a nut on the back like traditional rollers. Keep in mind, this reduces their radial capacity.

Rollers with a seal protect rolling elements from dirt and contamination better than shielded rollers, but they do hold more heat. The seal also helps retain lubrication.

Add a grease fitting to create a lubrication point.

Flanged Threaded Track Rollers

Thread the stud directly into a component or secure with a nut for through-hole mounting. The flange provides guidance and helps the roller stay on track. All rollers are permanently lubricated and have end seals to retain lubricant and protect rolling elements from dirt and contamination.

Roller | Stud | Thread | Shoulder | Flange | Static Load Cap., lbs. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Dia. | Lg. | Size | Lg. | Dia. | Lg. | OD | Thick. | Max. Speed, rpm | Radial | Thrust | Max. Temp., °F | Includes | Each | |

Steel Flat Rollers with Seal | ||||||||||||||||

Ball Bearing | ||||||||||||||||

| 35mm | 22mm | 16mm | 32.5mm | M16 | 18mm | 19.1mm | 0.8mm | 46mm | 5mm | Not Rated | 600 | 370 | 225° | Mounting Hardware | 00000000 | 000000 |

Tight-Tolerance Drive Rollers

The surface of these rollers is molded to a tolerance of either ±0.003 in. or ±0.08 mm to provide more consistent surface contact. Also known as contact wheels and feed rollers, they have tapped hubs that allow you to mount them onto a shaft or stud to transmit power. The urethane surface is nonmarring and wear resistant.

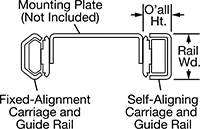

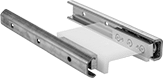

Side-Mount Track Roller Carriages and Guide Rails

Mount along a wall or other vertical surface.

Carriages with adjustable rollers can be adjusted for a snug or loose fit on the rail (also known as preload).

Carriages with wipers sweep away dust and other contaminants.

Carriages with Adjustable Rollers | Guide Rails | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | Roller Dia., mm | Max. Temp., °F | Each | Rail Lengths, mm | Per mm | ||

Aluminum Carriages with Plastic Wipers and Steel Rollers | |||||||||||

| 65 | 1,300 | 42 | 51 | 162 | 35 | 175° | 00000000 | 0000000 | 0000000 | 00000 | |

| 65 | 1,300 | 42 | 51 | 215 | 35 | 175° | 00000000 | 000000 | 0000000 | 000 | |

| 65 | 2,000 | 42 | 51 | 269 | 35 | 175° | 00000000 | 000000 | 0000000 | 000 | |

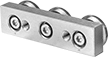

Self-Aligning Side-Mount Track Roller Carriages and Guide Rails

Create a self-aligning carriage and guide rail system to compensate for mounting surfaces that aren't parallel. The floating bearing in these carriages adjusts to correct misalignment between rails, so your carriages still move in tandem. A complete system includes a fixed-alignment carriage and rail on one side and a self-aligning carriage and rail on the other. All components are sold separately.

Carriages can be adjusted for a snug or loose fit on the rail (also known as preload). They have permanently lubricated rollers to save maintenance time and effort.

Self-aligning rails have a rectangular profile that allows the carriage to move freely from side to side to compensate for misalignment.