Extra-Flexible Coated Corrosion-Resistant Wire Rope—Not for Lifting

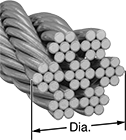

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys and the stainless steel wire rope withstands outdoor and washdown applications. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

Coated Wire Rope—Not for Lifting

The construction of this wire rope provides a good balance of abrasion resistance and flexibility. The galvanized finish is corrosion resistant. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut. Extra-lubricated wire rope has an additional coating of lubrication for added wear and corrosion resistance.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

| Dia. | Dia. with Coating | Cap., lbs. | Recommended Pulley/Drum Dia. | Coating Material | Lubrication | Temp. Range, °F | Specifications Met | Choose a Coating Color | Lengths, ft. | Per Ft. | |

Galvanized Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

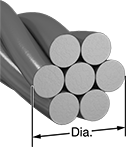

7 × 7—Strand Core | |||||||||||

| 0.047" | 1/16" | 50 | 1 15/16" | Nylon Plastic | Lubricated | -65° to 200° | __ | 00000000 | 00000 | ||

| 0.047" | 1/16" | 50 | 1 15/16" | Nylon Plastic | Extra Lubricated | -65° to 200° | MIL-DTL-83420 | Clear | 0000000 | 000 | |

Coated Corrosion-Resistant Wire Rope—Not for Lifting

This stainless steel wire rope withstands outdoor and washdown applications. The construction of this wire rope provides a good balance of abrasion resistance and flexibility. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut. Extra-lubricated wire rope has an additional coating of lubrication for added wear and corrosion resistance.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

| Dia. | Dia. with Coating | Cap., lbs. | Recommended Pulley/Drum Dia. | Coating Material | Lubrication | Temp. Range, °F | Specifications Met | Choose a Coating Color | Lengths, ft. | Per Ft. | |

18-8 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

7 × 7—Strand Core | |||||||||||

| 0.047" | 1/16" | 50 | 1 15/16" | Nylon Plastic | Lubricated | -40° to 180° | __ | 00000000 | 00000 | ||

| 0.047" | 1/16" | 50 | 1 15/16" | Nylon Plastic | Extra Lubricated | -65° to 200° | MIL-DTL-83420 | Clear | 0000000 | 000 | |

Weather-Resistant Coated Wire Rope—Not for Lifting

Coated with vinyl, this wire rope resists UV rays better than nylon-coated wire rope. The construction of this wire rope provides a good balance of abrasion resistance and flexibility. The galvanized finish is corrosion resistant. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

Weather-Resistant Coated Corrosion-Resistant Wire Rope—Not for Lifting

This stainless steel wire rope withstands outdoor and washdown applications. The construction of this wire rope provides a good balance of abrasion resistance and flexibility. Coated with vinyl, this wire rope resists UV rays better than nylon-coated wire rope. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

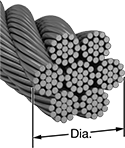

Extra-Flexible Chemical-Resistant Coated

Corrosion-Resistant Wire Rope—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys and the stainless steel wire rope withstands outdoor and washdown applications. An impregnated coating provides additional resistance over other coated wire rope.

Preformed wire rope maintains its shape when cut and resists unraveling.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

Chemical-Resistant Coated Corrosion-Resistant Wire Rope—Not for Lifting

This stainless steel wire rope withstands outdoor and washdown applications. The construction of this wire rope provides a good balance of abrasion resistance and flexibility. An impregnated coating provides additional resistance over other coated wire rope. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Note: When attaching fittings to coated rope, the coating must be removed from the installation area.

Coated Small-Diameter Braided Wire—Not for Lifting

The plastic coating protects this braided wire from abrasion. Made of 18-8 stainless steel, this wire rope has good corrosion resistance. This wire rope provides a good balance of abrasion resistance and flexibility.

Preformed wire rope maintains its shape when cut and resists unraveling.

Strand core are more crush resistant than hollow core.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

Difficult-to-Bend Corrosion-Resistant

Small-Diameter Braided Wire—Not for Lifting

This braided wire has a stiff construction for use as bracing and guy wires. This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Extra-lubricated braided wire has an additional coating of lubrication for added wear and corrosion resistance.

| Dia. | Capacity, lbs. | Recommended Pulley/Drum Dia. | Lubrication | Specifications Met | Lengths, ft. | Per Ft. | |

18-8 Stainless Steel | |||||||

|---|---|---|---|---|---|---|---|

1 × 7—Strand Core | |||||||

| 0.047" | 70 | Not Rated | Lubricated | __ | 000000 | 00000 | |

| 0.047" | 70 | Not Rated | Extra Lubricated | MIL-DTL-87161 | 00000000 | 000 | |

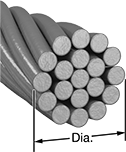

1 × 19—Strand Core | |||||||

| 0.047" | 70 | Not Rated | Lubricated | __ | 00000000 | 000 | |

| 0.047" | 70 | Not Rated | Extra Lubricated | MIL-DTL-87161 | 0000000 | 000 | |

Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down. This wire rope provides a good balance of abrasion resistance and flexibility.

Preformed wire rope maintains its shape when cut and resists unraveling.

Extra-lubricated braided wire has an additional coating of lubrication for added wear and corrosion resistance.

Strand core is more crush resistant than hollow core.

Extra-Flexible Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys. This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down.

Preformed wire rope maintains its shape when cut and resists unraveling.

Small-Diameter Braided Wire—Not for Lifting

This wire rope is often used for lightweight suspending applications, such as hanging light fixtures. This wire rope provides a good balance of abrasion resistance and flexibility. The galvanized finish is corrosion resistant. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

Difficult-to-Bend Small-Diameter Braided Wire—Not for Lifting

This braided wire has a stiff construction for use as bracing and guy wires. This wire rope is often used for lightweight suspending applications, such as hanging light fixtures. The galvanized finish is corrosion resistant. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut. Extra-lubricated braided wire has an additional coating of lubrication for added wear and corrosion resistance.

Nonsparking Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

Not only is this phosphor bronze braided wire corrosion resistant, it inhibits sparking. This wire rope provides a good balance of abrasion resistance and flexibility.

Preformed wire rope maintains its shape when cut and resists unraveling.

Ultra-Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

The superior corrosion resistance of nickel-copper makes this braided wire best for use with salt water and acidic- and alkaline-based solutions. This wire rope provides a good balance of abrasion resistance and flexibility. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.