Filter by

System of Measurement

Diameter

Construction

Application

Weight Capacity

Maximum Temperature

Performance

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Strand Color

Component

Fitting Type

Flexibility

Environment

Load Securement Type

High-Temperature Wear-Resistant Rope—For Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aramid | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyester Plastic Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 2,000 | 300 | White with Red and Yellow Strands | Yes | 5 , 10 , 25 , 50 , 75 , 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Aramid Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 2,100 | 480 | Brown | Yes | 5 , 10 , 25 , 50 , 75 , 100 , 200 , 300 , 600 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wet-Environment Easy-Splice Rope—For Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Can Be Spliced | Choose a Color | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane-Coated Dyneema Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided with Hollow Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,300 | 150 | Yes | Black , Blue , Gray , Green , Orange , Red , Yellow | 5 , 10 , 25 , 50 , 75 , 100 , 200 , 300 , 600 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Comfort-Grip Low-Stretch Sure-Grip Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyester/Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twisted | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 350 | 200 | White with Orange Strands | Yes | 25 , 50 , 100 , 200 , 300 , 600 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UV-Resistant Wet-Environment Sure-Grip Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twisted | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 250 | 200 | Black with Orange Strands | Yes | 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shock-Absorbing Wear-Resistant Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Nylon Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 450 | 300 | White with Blue and Red Strands | Yes | 25 , 50 , 100 , 200 , 300 , 600 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyurethane-Coated Polyester Plastic Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 500 | 300 | White with Blue Strands | Yes | 25 , 50 , 100 , 200 , 300 , 600 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shock-Absorbing No-Flatten Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 250 | 300 | White | No | 25 , 100 , 200 , 500 , 1,000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wet-Environment Wear-Resistant Rope—For Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyurethane-Coated Polyester Plastic Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1,980 | 150 | White with Red Strands | Yes | 10 , 25 , 50 , 75 , 100 , 200 , 300 , 600 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All-Weather EPDM Cords

Dia. | Material | Color | Choose a Length, ft. | Per Ft. | |||

|---|---|---|---|---|---|---|---|

| 7/16" | EPDM | Black | 25 , 50 , 100 , 200 , 600 | 0000000 | 00000 | ||

Low-Stretch Wear-Resistant Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyester Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyester Plastic Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 400 | 200 | White with Red Strands | No | 10 , 50 , 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyurethane-Coated Polyester Plastic Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 500 | 200 | White with Blue Strands | No | 10 , 25 , 50 , 100 , 200 , 300 , 600 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Comfort-Grip Shock-Absorbing Wear-Resistant Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Lg., ft. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Cotton Cover with Braided Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 250 | 150 | White with Red Strands | No | 100 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Flexible Wire Rope for Lifting

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Specifications Met | Choose a Length, ft. | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,000 | 6 × 19 IWRC | 12" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,000 | 6 × 19 IWRC | 14 7/8" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,000 | 7 × 19 IWRC | 11 3/8" | Yes | ASTM A1023 | 2 , 5 , 10 , 25 , 50 , 100 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3,100 | 6 × 19 IWRC | 10 1/2" | Yes | Fed. Spec. RR-W-410 | 10 , 25 , 50 , 100 , 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shock-Absorbing Flexible Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided Polyester Plastic Cover with Strand Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 620 | 300 | Black/White | No | 10 , 25 , 50 , 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shock-Absorbing Easy-Splice Rope—Not for Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane-Coated Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided with Hollow Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 500 | 300 | White | Yes | 10 , 25 , 50 , 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

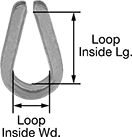

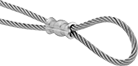

Heavy Duty Wire Rope Thimbles—For Lifting

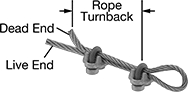

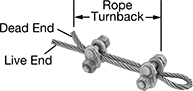

Crosby Forged Single-Saddle Wire Rope Clamps—Not for Lifting

For Wire Rope | Clamp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Number of Clamps Required | Rope Turnback | Wd. | Ht. | Thk. | Color | Fabrication | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | Specs. Met | 1-9 | 10-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 19 × 7 Strand Core | 2 3 | 11 1/2" | 2 5/16" | 2 3/8" | 1 15/16" | Red | Forged | 65 | 80% | ASME B30.26, Fed. Spec. FF-C-450 | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Stretch Easy-Splice Rope—Not For Lifting

Dia. | Wt. Cap., lb. | Max. Temp., ° F | Color | Can Be Spliced | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polyurethane-Coated Polyester Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Braided with Hollow Core | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 700 | 350 | White | Yes | 10 , 25 , 50 , 100 , 200 , 300 , 600 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Flexible Wire Rope for Lifting

Ultra-Flexible Wear-Resistant Wire Rope for Lifting

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Specifications Met | Choose a Length, ft. | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,700 | 6 × 26 IWRC | 13 1/8" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hydraulic Compression Tools for Wire Rope Sleeves

Tools | Replacement Dies | Replacement Cartridges | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Handle | |||||||||||

For Compression Sleeve Material (Wire Rope Dia.) | Material | Color | Overall Lg. | Includes | Each | Each | Each | ||||

| Aluminum (7/16") Copper (1/2") | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 00000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |

| Copper (7/16") | Fiberglass | Yellow | 23" | Cartridge, Die, Measuring Gauge, Case | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |

Crosby Forged Double-Saddle Wire Rope Clamps—Not for Lifting

For Wire Rope | Clamp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Number of Clamps Required | Rope Turnback | Wd. | Ht. | Thk. | Fabrication | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | Specs. Met | 1-9 | 10-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 7 × 19 IWRC 7 × 19 Strand Core 19 × 7 Strand Core | 2 3 | 6 1/2" 11" | 2 3/16" | 2 5/8" | 1 1/4" | Forged | 65 | 80% | ASME B30.26, Fed. Spec. FF-C-450 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Rope Compression Sleeves—Not for Lifting

Sleeves | Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wire Rope Dia. | Construction | Sleeve Lg. | Req. No. of Compressions | Rope Cap. Adjustment Factor | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 19 Strand Core 1 × 7 Strand Core 3 × 7 Hollow Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 6 × 7 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC | 1 7/8" | 6 | 100% | 5 | 0000000 | 000000 | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Rope Compression Sleeves—For Lifting

Sleeves | Tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wire Rope Dia. | Construction | Sleeve Lg. | Req. No. of Compressions | Rope Cap. Adjustment Factor | Specs. Met | Mil. Spec. | Pkg. Qty. | Pkg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3 × 7 IWRC 7 × 7 IWRC 7 × 19 IWRC 6 × 19 IWRC | 1 3/4" | 2 | 100% | ASME B30.9 | MS51844 | 1 | 0000000 | 000000 | 000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 3 × 7 IWRC 7 × 7 IWRC 7 × 19 IWRC 6 × 19 IWRC | 1 3/4" | 2 | 100% | ASME B30.9 | MS51844 | 1 | 0000000 | 00000 | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rotation-Resistant Wire Rope for Lifting

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Specifications Met | Choose a Length, ft. | Per Ft. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 4,400 | 18 × 7 IWRC | 14 7/8" | Yes | ASTM A1023 | 5 , 10 , 25 , 50 , 100 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

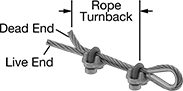

Cast Wire Rope Clamps—Not for Lifting

For Wire Rope | Clamp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Number of Clamps Required | Rope Turnback | Wd. | Ht. | Thk. | Fabrication | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 | 10 1/4" | 1 7/16" | 1 13/16" | 9/16" | Cast | 40 | Not Rated | 00000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 | 10 1/4" | 1 7/16" | 1 13/16" | 9/16" | Cast | 40 | Not Rated | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 | 10 1/4" | 1 7/16" | 1 13/16" | 9/16" | Cast | 40 | Not Rated | 00000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Rope Clamp and Thimble Kits—Not for Lifting

For Wire Rope | Clamp | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | No. of Clamps | Rope Turnback | Wd. | Ht. | Thk. | No. of Thimbles | Fabrication | Req. Torque, ft·lbf | Rope Cap. Adjustment Factor | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel Clamps with Galvanized Steel Thimble | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core 18 × 7 IWRC 19 × 7 Strand Core | 2 | 7" | 2 1/16" | 2 3/8" | 7/8" | 1 | Forged | 65 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Iron Clamps with Galvanized Steel Thimble | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 1 × 7 Strand Core 1 × 19 Strand Core 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 | 10 1/4" | 2 1/16" | 2 3/8" | 7/8" | 1 | Cast | 40 | Not Rated | Fed. Spec. FF-C-450 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Clamps with 18-8 Stainless Steel Thimble | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16", 1/2" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 | 11 1/2" | 2" | 2 1/2" | 1 1/2" | 1 | Cast | 45 | 80% | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||