Filter by

Material

System of Measurement

Weight Capacity

Application

Wire Rope Core Type

Flexibility

Wire Rope Coating

Bearing Type

Finish

Wire Rope Construction

Fitting Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Nonsparking Wire Rope

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Preformed | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Corrosion-Resistant Phosphor Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.031" | 8 | 6 × 7 Fiber Core | 1 5/16" | No | 10 , 25 , 50 , 100 , 300 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.031" | 8 | 7 × 7 Strand Core | 1 5/16" | No | 10 , 25 , 50 , 100 , 300 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.047" | 10 | 6 × 7 Fiber Core | 2" | Yes | 10 , 25 , 50 , 100 , 300 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 30 | 6 × 7 Fiber Core | 2 5/8" | Yes | 10 , 25 , 50 , 100 , 300 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 30 | 7 × 7 Strand Core | 2 5/8" | Yes | 10 , 25 , 50 , 100 , 300 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 60 | 6 × 7 Fiber Core | 2 15/16" | Yes | 5 , 10 , 25 , 50 , 100 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 100 | 6 × 7 Fiber Core | 5 1/4" | Yes | 5 , 10 , 25 , 50 , 100 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 100 | 7 × 7 Strand Core | 5 1/4" | Yes | 5 , 10 , 25 , 50 , 100 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra-Flexible Nonsparking Wire Rope

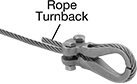

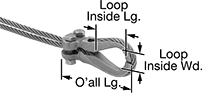

Wire Rope Clamps with Thimbles—Not for Lifting

|  |  |

For Wire Rope | Loop | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Rope Turnback | Inside Lg. | Inside Wd. | Overall Lg. | Fabrication | Req. Torque, ft·lbf | Wt. Cap., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core | 3 1/4" | 15/16" | 9/16" | 2 1/2" | Cast | 8 | 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core | 3 3/4" | 1 1/8" | 21/32" | 2 7/8" | Cast | 12 | 600 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core | 4 3/4" | 1 9/16" | 7/8" | 3 3/4" | Cast | 19 | 1,000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core | 5 1/4" | 1 15/16" | 1 1/16" | 4 5/8" | Cast | 19 | 1,600 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

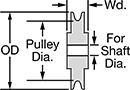

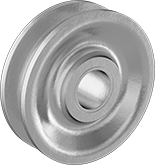

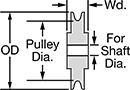

Pulleys for Wire Rope—For Lifting

|  |  |

Style B | Style C | Style J |

1 Groove With Plain Bearing

|  |  |  |

Style B | Style C | Style J |

Style | For Rope Dia. | Wt. Cap., lb. | OD | Wd. | Pulley Dia. | For Shaft Dia. | Material | Bearing Material | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | 3/64" | 20 | 3/4" | 3/16" | 5/8" | 1/8" | Nylon | Bronze | 0000000 | 00000 | ||

| B | 3/64" | 70 | 1 1/16" | 1/4" | 7/8" | 3/16" | Nylon | Bronze | 0000000 | 0000 | ||

| B | 3/64" | 70 | 1 1/16" | 1/4" | 7/8" | 1/4" | Nylon | Bronze | 0000000 | 0000 | ||

| B | 1/16" | 90 | 1 1/4" | 1/4" | 1 1/16" | 3/16" | Nylon | Bronze | 0000000 | 0000 | ||

| B | 3/32" | 150 | 1 1/2" | 5/16" | 1 1/4" | 3/8" | Nylon | Bronze | 0000000 | 0000 | ||

| C | 1/4" | 1,200 | 4" | 13/16" | 3 1/4" | 1/2" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 1/4" | 1,200 | 4" | 13/16" | 3 1/4" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 5/16" | 1,800 | 5" | 1" | 4" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 3/8" | 1,600 | 4" | 13/16" | 3 1/8" | 1/2" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 3/8" | 1,600 | 4 1/8" | 1 1/2" | 3" | 1" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 3/8" | 1,700 | 4" | 13/16" | 3 1/8" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 00000 | ||

| C | 3/8" | 2,700 | 6" | 1 1/8" | 4 15/16" | 1 1/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 3/8" | 2,800 | 6" | 1 1/16" | 5" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 3/8" | 2,800 | 6" | 1 1/16" | 5" | 1" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 3/8" | 3,600 | 8" | 1 3/8" | 6 1/2" | 1 1/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 1/2" | 3,200 | 6" | 1 1/16" | 4 7/8" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 1/2" | 3,600 | 6" | 1 1/16" | 4 7/8" | 1" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 1/2" | 3,600 | 6" | 1 1/8" | 4 15/16" | 1 1/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 1/2" | 4,800 | 8" | 1 3/8" | 6 5/8" | 1" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 5/8" | 3,200 | 6" | 1 1/16" | 5" | 3/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 5/8" | 4,200 | 6" | 1 1/16" | 5" | 1" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| C | 5/8" | 6,000 | 8" | 1 3/8" | 6 5/8" | 1 1/4" | Powder-Coated Steel | Bronze | 0000000 | 000000 | ||

| J | 1/16" | 90 | 1 1/4" | 1/4" | 1 1/16" | 1/4" | Nylon | Bronze | 0000000 | 0000 | ||

| J | 3/32" | 150 | 1 1/2" | 5/16" | 1 1/4" | 1/4" | Nylon | Bronze | 0000000 | 0000 | ||

Pulleys for Wire Rope—For Horizontal Pulling

|  |  |  |

Style A | Style B | Style C |

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Rope Dia. | Wt. Cap., lb. | OD | Wd. | Pulley Dia. | For Shaft Dia. | Material | Bearing Material | 1-24 | 25-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Groove With Plain Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4" | 1,000 | 3" | 9/16" | 2 3/8" | 3/8" | Steel | Bronze | 00000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8" | 1,200 | 4" | 13/16" | 3 1/4" | 3/4" | Steel | Bronze | 00000000 | 000000 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 7/8" | 4,300 | 5 7/8" | 1 3/4" | 4 3/8" | 1 1/2" | Steel | Bronze | 0000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/8" | 1,000 | 2 1/4" | 13/16" | 1 7/8" | 1/4" | Stainless Steel | Bronze | 00000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/16" | 1,000 | 2" | 9/16" | 1 1/2" | 3/8" | Stainless Steel | Bronze | 000000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/16" | 1,500 | 3 1/4" | 15/16" | 2 3/4" | 3/8" | Stainless Steel | Bronze | 00000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/4" | 1,500 | 2 1/2" | 11/16" | 1 7/8" | 5/8" | Stainless Steel | Bronze | 000000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/4" | 3,000 | 4 1/4" | 1 1/8" | 3 1/2" | 1/2" | Stainless Steel | Bronze | 00000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/16" | 5,000 | 5 1/4" | 1 3/8" | 4 3/8" | 1/2" | Stainless Steel | Bronze | 00000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/8" | 8,000 | 6 1/4" | 1 5/8" | 5 1/4" | 1/2" | Stainless Steel | Bronze | 00000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

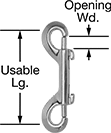

Dual Slide-Bolt-Latch Snap Hooks

|

Wt. Cap. | Snap Opening Wd. | Usable Lg. | Latch Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | 7/16" | 4 1/8" | Slide Bolt | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hanging Pulleys for Rope—For Horizontal Pulling

Mounted Pulleys for Rope—For Horizontal Pulling

|  |

Style 1 | Style 2 |

| |

Styles 1, 3, and 5-8 | |

Styles 2 and 4 |

Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Rope Dia. | Wt. Cap. | OD | Wd. | Overall Lg. | Overall Ht. | Material | Housing Material | No. of | Dia. | Ctr.-to-Ctr. (A) | Ctr.-to-Ctr. (B) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Groove Without Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/4" | Not Rated | 11/16" | 7/8" | 1 7/8" | 1 1/8" | Bronze | Bronze | 2 | 5/32" | 1 3/8" | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/8" | Not Rated | 1 1/2" | 2 1/2" | 2 1/8" | 2 1/8" | Bronze | Bronze | 4 | 17/64" | 1 3/8" | 1 3/4" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||