Filter by

For Use On

Cutting Diameter

Length of Cut

Cut Style

Tool Type

Sold As

Overall Length

Shank Type

Chip Removal Direction

Pilot Location

Router Bit Pilot Type

Length

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Router Bit Sets

|  |  |  |

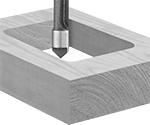

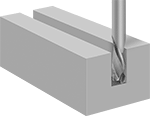

Chamfering Cut Style | Corner Cut Style | Square Cut Style | Flush-Trimming Cut Style |

|  |  |  |

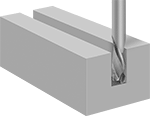

Groove Cut Style | Hinge Mortise Cut Style | Joining Cut Style | Panel Groove Cut Style |

|  | ||

Panel Pilot Cut Style |

No. of Pieces | Cut Style | Includes | Shank Dia. | For Tool Type | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Uncoated Carbide-Tipped High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multipurpose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | Chamfering Corner Rounding Square Flush Trimming Joining | One Chamfer Router Bit: 1-5/16" Cutting Diameter One Flush-Trimming Router Bit: 3/8" Cutting Diameter One Dovetail Router Bit: 1/2" Cutting Diameter One Rounded-Corner Bit: 1/4" Cutting Diameter Two Square Router Bits: 1/4" and 1/2" Cutting Diameters | 1/4" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | Square | Six Square Router Bits: 1/4", 5/16", 3/8", 1/2", 5/8", and 3/4" Cutting Diameters | 1/4" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | Chamfering Corner Rounding Square Flush Trimming Groove Hinge Mortise Joining | One Chamfer Router Bit: 1-5/16" Cutting Diameter Two Rounded-Corner Bits: 1/4" and 3/8" Cutting Diameters One Flush-Trimming Router Bit: 1/2" Cutting Diameter One Rounded-Groove Router Bit: 1/4" Cutting Diameter One V-Groove Router Bit: 9/16" Cutting Diameter One Hinge-Mortise Router Bit: 1/2" Cutting Diameter One Dovetail Router Bit: 1/2" Cutting Diameter Two Square Router Bits: 1/4" and 3/4" Cutting Diameters | 1/2" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | Chamfering Corner Rounding Square Flush Trimming Groove Joining | Two Chamfer Router Bits: 1" and 1-3/8" Cutting Diameters Two Rounded-Corner Bits: 1/8" and 1/4" Cutting Diameters One Cove Router Bit: 3/8" Cutting Diameter Two Flush-Trimming Router Bits: 1/2" and 5/8" Cutting Diameters One V-Groove Router Bit: 5/8" Cutting Diameter One Dovetail Router Bit: 9/16" Cutting Diameter One Roman Ogee Router Bit: 5/32" Cutting Diameter One Slotting Router Bit: 1-1/4" Cutting Diameter One Tongue-and-Groove Router Bit: 1-1/4" Cutting Diameter Three Square Router Bits: 1/4", 1/2", and 5/8" Cutting Diameters | 1/4" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | Chamfering Corner Rounding Square Flush Trimming Groove Hinge Mortise Joining Panel Pilot | Two Chamfer Router Bits: 1" and 1-3/8" Cutting Diameters One Beaded-Corner Router Bit: 1-1/16" Cutting Diameter One Wavy-Corner Router Bit: 1-1/4" Cutting Diameter Five Rounded-Corner Router Bits: 1/8", 1/4", 5/16", 3/8", and 1/2" Cutting Diameters Two Cove Router Bits: 7/8" and 1-1/8" Cutting Diameters One Dovetail Router Bit: 9/16" Cutting Diameter One Hinge-Mortise Router Bit: 1/2" Cutting Diameter One Panel-Pilot Router Bit: 5/16" Cutting Diameter Three Flush-Trimming Router Bits: 1/2" and 5/8" Cutting Diameters Two Rabbet Router Bits: 1-1/4" Cutting Diameter Two Rounded-Groove Router Bits: 1/2" and 3/4" Cutting Diameters Two V-Groove Router Bits: 5/8" Cutting Diameter Seven Square Router Bits: 5/32", 1/4", 5/16", 3/8", 1/2", 5/8", and 3/4" Cutting Diameters | 1/4" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cabinetmaking | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | Joining Panel Groove | Two Lock Miter Router Bits: 1-5/8" Cutting Diameter One Roman Ogee Router Bit: 3-3/8" Cutting Diameter | 1/2" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trimming, Edging | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | Chamfering Corner Rounding Flush Trimming | Two Chamfer Router Bits: 1" and 1-3/8" Cutting Diameters Two Rounded-Corner Bits: 1/8" and 1/4" Cutting Diameters Two Flush-Trimming Router Bits: 1/2" and 5/8" Cutting Diameters | 1/4" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wood Joining | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | Joining | Two Lock Miter Router Bits: 1-5/8" Cutting Diameter | 1/2" | Hand Router, Router Table | Softwood, Hardwood, Plastic, Laminate, Composite | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight and Spiral Router Bits for Foam

Uncoated High-Speed Steel

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

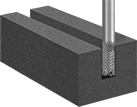

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/8" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 1/4" | 3 1/4" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 1/2" | 2 1/2" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1" | 3/8" | 2 1/2" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/4" | 1/2" | 2 3/4" | 2 | Hand Router, Router Table, CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated Carbide

|

Square Cut Style—Plunge-Cut |

Square Cut Style—Plunge-Cut, Spiral Flute |

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 5/8" | 3/16" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | 1/4" | 6" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4" | 3/8" | 6" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/16" | 1/8" | 3" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic-Coated Carbide

|

Square Cut Style—Plunge-Cut |

Square Cut Style—Plunge-Cut, Spiral Flute |

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/8" | 1/4" | 2 1/2" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 1/4" | 4" | 2 | CNC Machine | Foam | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trimming Router Bits

Uncoated Carbide

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Router Bit Pilot Type | Ball Bearing Pilot Dia. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

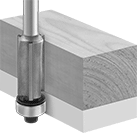

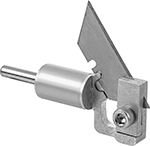

Flush-Trimming Cut Style (Bottom Pilot) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/8" | 1/4" | 2 3/8" | Ball Bearing | 1/4" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Aluminum, Laminate, Foam, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 3" | Ball Bearing | 1/4" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Laminate, Foam, Composite | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/8" | 1/2" | 4" | Ball Bearing | 1/2" | 2 | Hand Router, Router Table | Wood, Particleboard, Plywood, Hard Plastic, Soft Plastic, Laminate, Foam, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamond-Coated Router Bits for Composites

Diamond-Coated Carbide

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

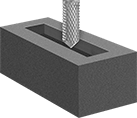

Square Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 10 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1" | 3/8" | 3" | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/4" | 1/2" | 3 1/2" | 15 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 5/8" | 5/8" | 4" | 15 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 10 mm | 6 mm | 57 mm | 6 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 15 mm | 6 mm | 65 mm | 8 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 20 mm | 8 mm | 75 mm | 10 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 25 mm | 10 mm | 80 mm | 12 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 32 mm | 12 mm | 93 mm | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drill/Mill Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 10 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1" | 3/8" | 3" | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/4" | 1/2" | 3 1/2" | 15 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 5/8" | 5/8" | 4" | 15 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 12 mm | 4 mm | 55 mm | 6 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 18 mm | 6 mm | 65 mm | 8 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 24 mm | 8 mm | 75 mm | 10 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 30 mm | 10 mm | 80 mm | 12 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 36 mm | 12 mm | 93 mm | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 48 mm | 16 mm | 108 mm | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 10 mm | 6 mm | 57 mm | 6 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 15 mm | 6 mm | 65 mm | 8 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 20 mm | 8 mm | 75 mm | 10 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 25 mm | 10 mm | 80 mm | 12 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 32 mm | 12 mm | 93 mm | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 34 mm | 16 mm | 108 mm | 14 | CNC Machine | Fiber-Reinforced Plastic, Composite | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60° Compression Spiral Flutes with Upward and Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 3" | 2 | Router Table, CNC Machine | Carbon Fiber, Fiber-Reinforced Plastic, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/4" | 3/8" | 3" | 2 | Router Table, CNC Machine | Carbon Fiber, Fiber-Reinforced Plastic, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2" | 3/8" | 4" | 2 | Router Table, CNC Machine | Carbon Fiber, Fiber-Reinforced Plastic, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1" | 1/2" | 3" | 2 | Router Table, CNC Machine | Carbon Fiber, Fiber-Reinforced Plastic, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2" | 4" | 2 | Router Table, CNC Machine | Carbon Fiber, Fiber-Reinforced Plastic, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Router Bits for Thin Materials

Uncoated Carbide

Cut Radius | Lg. of Cut | Cut Angle | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

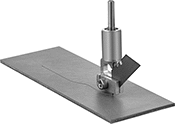

Drag Knife Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/64" | 1/32" | 45°, 60° | 1/4" | 2 1/4" | 1 | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated Steel

|  |

Drag Knife Cut Style |

Cut Radius | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | Heat Treatment | For Tool Type | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drag Knife Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 1/16" | 1/4" | 3 1/4" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 1/16" | 1/2" | 4 1/2" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/4" | 1/4" | 3 1/2" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1/4" | 1/2" | 4 3/8" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 1/2" | 1/2" | 4 3/4" | 1 | Hardened | CNC Machine | Fabric, Leather, Paper, Rubber, Vinyl Plastic | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

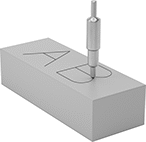

Engraving Router Bits

Uncoated Diamond-Tipped Stainless Steel

Bits | Replacement 120° Cut Angle Tips | 90° Cut Angle Tips | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cutting Dia. | Lg. of Cut | Cut Angle | Shank Dia. | Overall Lg. | For Tool Type | For Use On | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Engraving Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluteless | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | 1/32" | 120° | 1/4" | 3 3/4" | CNC Machine | Wood, Hard Plastic, Aluminum, Copper, Steel, Granite, Glass, Plastic, Foam | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | 1/32" | 120° | 1/2" | 3 3/4" | CNC Machine | Wood, Hard Plastic, Aluminum, Copper, Steel, Granite, Glass, Plastic, Foam | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plotter Pen Router Bits

Router Bits | Replacement Pens | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Tip Size | Stroke Wd., mm | For Use On | Drying Time | Shank Dia. | Overall Lg. | For Tool Type | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fluteless | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medium | 1.3 | Ceramic, Foam, Glass, Particleboard, Plastic, Plywood, Steel, Wood | Instant | 1/2" | 4 1/16" | CNC Machine | Four Pens (Black, Blue, Green, Red) | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||