Filter by

System of Measurement

Tool Type

Cut Style

Chip Removal Direction

Shank Type

Sold As

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Router Bit Pilot Type

Wood Joint Type

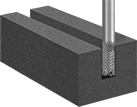

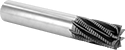

Spiral Router Bits for Steel and Stainless Steel

Aluminum Titanium Nitride (AlTiN)-Coated Carbide

| |

Square Cut Style Spiral Flute 4 Flutes |

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | 1/16" | 1/8" | 1 1/2" | 4 | CNC Machine | Steel, Stainless Steel | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 3/16" | 1/8" | 1 1/2" | 4 | CNC Machine | Steel, Stainless Steel | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 3/8" | 1/4" | 1 1/2" | 4 | CNC Machine | Steel, Stainless Steel | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/8" | 1/4" | 2 3/8" | 4 | CNC Machine | Steel, Stainless Steel | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/8" | 1/4" | 3" | 4 | CNC Machine | Steel, Stainless Steel | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

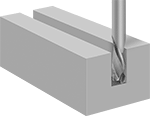

Drill/Mill Router Bits

Uncoated High-Speed Steel

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drill/Mill Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1 1/4" | 1/4" | 2 3/4" | 4 | Hand Router, Router Table, CNC Machine | Cast Iron, Copper, Steel, Stainless Steel, Titanium | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamond-Coated Router Bits for Composites

Diamond-Coated Carbide

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | No. of Flutes | For Tool Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Square Cut Style—Plunge-Cut | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roughed Spiral Flutes with Upward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/64" | 3/4" | 1/4" | 2 1/2" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/2" | 1/4" | 2 1/2" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 1/4" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

45° Compression Angle Spiral Flutes with Upward and Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/4" | 3/8" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2" | 3/8" | 4" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1" | 1/2" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2" | 4" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30° Compression Angle Herringbone Compression Flutes with Upward and Downward Chip Removal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 9/16" | 1/8" | 1 1/2" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 2 1/2" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 7/8" | 3/8" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/2" | 1/2" | 3" | 4 | Router Table, CNC Machine | Carbon Fiber, Fiberglass, Composite | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

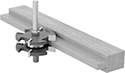

Router Bits for Wood Joining

Tongue-and-Groove Wood Joint—Uncoated Carbide-Tipped Steel

Cutting Dia. | Lg. of Cut | Shank Dia. | Overall Lg. | Router Bit Pilot Type | No. of Flutes | For Tool Type | For Use On | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Joining Cut Style | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Flutes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3/4" | 1/4" | 2 27/32" | Solid | 4 | Hand Router, Router Table | Wood, Particleboard, Plywood | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||