Filter by

System of Measurement

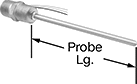

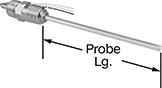

Probe Length

RTD Sensor Connection

Maximum Temperature

Probe Material

Probe Movement

Minimum Temperature

Overall Length

Electrical Connection

Fitting Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

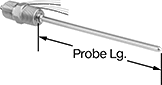

Threaded RTD Probes for Liquids and Gas

Wire-Lead Connection

Probe | Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Temp. Range, ° F | Lg. | Dia. | Accuracy | Response Time, sec. | Probe Connection Pipe Size | Fitting Material | Lead Lg. | AWG | No. of Wires | Wire Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 304 Stainless Steel Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 3" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 4 1/2" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 6" | 1/4" | ±0.12% | 3.5 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 6 5/8" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 12" | 1/4" | ±0.12% | 3.5 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 12 5/8" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 18" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 24" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 36" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 316 Stainless Steel Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 1,200 | 6" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Spring Loaded 304 Stainless Steel Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 6" | 1/4" | ±0.12% | 10 | 1/2 | 304 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 12" | 1/4" | ±0.12% | 10 | 1/2 | 304 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 18" | 1/4" | ±0.12% | 10 | 1/2 | 304 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 24" | 1/4" | ±0.12% | 10 | 1/2 | 304 Stainless Steel | 3" | 24 | 3 | Red/White | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

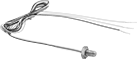

Threaded RTD Probes for Surfaces

|  |  |

Style A | Style B | Style C |

Micro M12 Plug Connection

Probe | Cable | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | RTD Probe Resistance, ohm | Temp. Range, ° F | Thread Size | Lg. | Wd. | Thk. | Accuracy | Response Time, sec. | Max. Pressure | Lg., ft. | Material | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Probe (IP67) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 | -40 to 190 | M5 × 0.8 mm | 15/16" | 0.313" | 0.188" | ±0.5% | 8 | Not Rated | 6 | Polyurethane Rubber | EN 60751 Class A | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 | -40 to 190 | M6 × 1 mm | 15/16" | 0.313" | 0.188" | ±0.5% | 9 | Not Rated | 6 | Polyurethane Rubber | EN 60751 Class A | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 | -20 to 350 | M5 × 0.8 mm | 15/16" | 0.313" | 0.188" | ±0.5% | 8 | Not Rated | 6 | Silicone Rubber | EN 60751 Class A | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 | -20 to 350 | M6 × 1 mm | 15/16" | 0.313" | 0.188" | ±0.5% | 8 | Not Rated | 6 | Silicone Rubber | EN 60751 Class A | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire-Ferrule Connection

Probe | Cable | Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | RTD Probe Resistance, ohm | Temp. Range, ° F | Thread Size | Lg. | Wd. | Thk. | Accuracy | Response Time, sec. | Max. Pressure | Lg., ft. | Material | Lead Lg. | AWG | No. of Wires | Wire Color | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel Probe (IP67) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 100 | -20 to 300 | M12 × 1.5 mm | 1 3/16" | 0.375" | 0.688" | ±0.5% | 12 | Not Rated | 16 | Silicone Rubber | 1" | 22 | 4 | Red/White | EN 60751 Class A | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire-Lead Connection

Probe | Cable | Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | RTD Probe Resistance, ohm | Temp. Range, ° F | Thread Size | Lg. | Accuracy | Response Time, sec. | Max. Pressure | Lg., ft. | Material | Lead Lg. | AWG | No. of Wires | Wire Color | Specs. Met | Mil. Spec. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 100 | -55 to 500 | 1/4"-20 | 3/8" | ±0.12% | 10 | Not Rated | 3 | PTFE | 1/2" | 26 | 3 | Red/White | EN 60751 Class B | MIL-STD-202 Method 204 Test Condition D | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1,000 | -55 to 500 | 1/4"-20 | 3/8" | ±0.12% | 10 | Not Rated | 3 | PTFE | 1/2" | 24 | 2 | Red/White | — | MIL-STD-202 Method 204 Test Condition D | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded RTD Probe Transmitters for Liquids and Gas

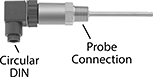

Circular DIN Connection

Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Lg. | Dia. | Accuracy | Response Time | Probe Connection Pipe Size | Voltage, V DC | Max. Pressure, psi | Output Current, mA | Overall Lg. | Fitting Material | Choose a Temperature, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 316 Stainless Steel Probe with Plastic Head (IP65) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 1 3/4" | 1/4" | ±0.5% | Not Rated | 1/2 | 10 to 30 | 725 | 4 to 20 | 5 3/4" | 316 Stainless Steel | -40 to 120 , 0 to 250 , 50 to 400 | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 3 1/4" | 1/4" | ±0.5% | Not Rated | 1/2 | 10 to 30 | 725 | 4 to 20 | 7 1/4" | 316 Stainless Steel | -40 to 120 , 0 to 250 , 50 to 400 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 5 1/4" | 1/4" | ±0.5% | Not Rated | 1/2 | 10 to 30 | 725 | 4 to 20 | 9 1/4" | 316 Stainless Steel | -40 to 120 , 0 to 140 , 50 to 400 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 8 1/4" | 1/4" | ±0.5% | Not Rated | 1/2 | 10 to 30 | 725 | 4 to 20 | 12 1/4" | 316 Stainless Steel | -40 to 120 , 0 to 200 , 50 to 400 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 11 1/4" | 1/4" | ±0.5% | Not Rated | 1/2 | 10 to 30 | 725 | 4 to 20 | 15 1/4" | 316 Stainless Steel | -40 to 120 , 0 to 250 , 50 to 400 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4-Pole Micro M12 Plug-In Connection

Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Lg. | Dia. | Accuracy | Response Time, sec. | Probe Connection Pipe Size | Voltage, V DC | Max. Pressure, psi | Output Current, mA | Communication Protocol | Overall Lg. | Fitting Material | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 316L Stainless Steel Probe (IP67, IP68, IP69K) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 11/16" | 1/4" | ±0.5% | 3 | 1/2 | 18 to 32 | 5,800 | 4 to 20 | IO Link | 4 1/8" | 316L Stainless Steel | 0 to 300 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 1 1/2" | 1/4" | ±0.5% | 3 | 1/2 | 18 to 32 | 4,350 | 4 to 20 | IO Link | 5" | 316L Stainless Steel | 0 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 3 1/2" | 1/4" | ±0.5% | 3 | 1/2 | 18 to 32 | 4,350 | 4 to 20 | IO Link | 7" | 316L Stainless Steel | 0 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 5 7/16" | 1/4" | ±0.5% | 3 | 1/2 | 18 to 32 | 4,350 | 4 to 20 | IO Link | 8 7/8" | 316L Stainless Steel | 0 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

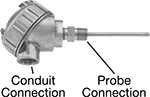

Screw-Terminal Connection

RTDs | Replacement RTD Elements | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Probe | Conduit Connection | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RTD Probe Resistance, ohm | Lg. | Dia. | Accuracy | Response Time, sec. | Probe Connection Pipe Size | Pipe Size | Thread Type | Gender | Voltage, V DC | Max. Pressure | Output Current, mA | Overall Lg. | Fitting Material | Choose a Temperature, ° F | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Spring Loaded 316 Stainless Steel Probe with Aluminum Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 3 3/4" | 1/4" | ±0.1% | 6 | 1/2 | 3/4 | NPT | Female | 10 to 30 | Not Rated | 4 to 20 | 9" | 316 Stainless Steel | 0 to 100 , 0 to 200 , 0 to 300 , 0 to 400 | 0000000 | 0000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 5 3/4" | 1/4" | ±0.1% | 6 | 1/2 | 3/4 | NPT | Female | 10 to 30 | Not Rated | 4 to 20 | 11" | 316 Stainless Steel | 0 to 100 , 0 to 200 , 0 to 300 , 0 to 400 | 0000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 8 3/4" | 1/4" | ±0.1% | 6 | 1/2 | 3/4 | NPT | Female | 10 to 30 | Not Rated | 4 to 20 | 14" | 316 Stainless Steel | 0 to 100 , 0 to 200 , 0 to 300 , 0 to 400 | 0000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 11 3/4" | 1/4" | ±0.1% | 6 | 1/2 | 3/4 | NPT | Female | 10 to 30 | Not Rated | 4 to 20 | 17" | 316 Stainless Steel | 0 to 100 , 0 to 200 , 0 to 300 , 0 to 400 | 0000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

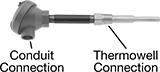

Threaded RTD Probes with Thermowell for Liquids and Gas

Screw-Terminal Connection

Probe | Thermowell Connection | Conduit Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Temp. Range, ° F | Lg. | Dia. | Accuracy | Response Time, sec. | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Overall Lg. | Fitting Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Loaded 304 Stainless Steel Probe with Thermowell and Cast Iron Head (IP65, NEMA 4) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 6" | 1/2" | ±0.12% | 30 | 3/4 | NPT | Male | 3/4 | NPT | Female | 14 1/8" | Iron | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 9" | 1/2" | ±0.12% | 30 | 3/4 | NPT | Male | 3/4 | NPT | Female | 17 1/8" | Iron | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 12" | 1/2" | ±0.12% | 30 | 3/4 | NPT | Male | 3/4 | NPT | Female | 20 1/8" | Iron | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

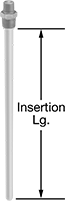

Thermocouple and RTD Protection Tubes

Thermowell Connection | Conduit Connection | Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Max. Temp., ° F | Insertion Lg. | For Max. Probe Dia. | Overall Lg. | Inner Dia. | Outer Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 1/2 | NPT | Male | 1,000 | 10 1/4" | 3/8" | 12" | 3/8" | 9/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,000 | 10 1/4" | 1/2" | 12" | 5/8" | 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,000 | 16 1/4" | 1/2" | 18" | 5/8" | 7/8" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,000 | 22 1/4" | 1/2" | 24" | 5/8" | 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 1 | NPT | Male | 1,000 | 10 1/4" | 3/4" | 12" | 7/8" | 1 1/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 1/2 | NPT | Male | 1,700 | 10 1/4" | 3/8" | 12" | 3/8" | 9/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 1/2 | NPT | Male | 1,700 | 16 1/4" | 3/8" | 18" | 3/8" | 9/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | NPT | Male | 1/2 | NPT | Male | 1,700 | 22 1/4" | 3/8" | 24" | 3/8" | 9/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,700 | 10 1/4" | 1/2" | 12" | 5/8" | 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,700 | 16 1/4" | 1/2" | 18" | 5/8" | 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 1,700 | 22 1/4" | 1/2" | 24" | 5/8" | 7/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 1 | NPT | Male | 1,700 | 16 1/4" | 3/4" | 18" | 7/8" | 1 1/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | NPT | Male | 1 | NPT | Male | 1,700 | 22 1/4" | 3/4" | 24" | 7/8" | 1 1/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 3,100 | 11 1/4" | 7/16" | 13 1/8" | 7/16" | 11/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 3,100 | 17 1/4" | 7/16" | 19 1/8" | 7/16" | 11/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | NPT | Male | 3/4 | NPT | Male | 3,100 | 23 1/4" | 7/16" | 25 1/8" | 7/16" | 11/16" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dual-Output Threaded RTD Probes for Liquids and Gas

Wire-Lead Connection

Probe | Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Temp. Range, ° F | Lg. | Dia. | Accuracy | Response Time, sec. | Probe Connection Pipe Size | Fitting Material | Lead Lg. | AWG | No. of Wires | Wire Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 304 Stainless Steel Probe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 6" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 6 | Red/White | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 12" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 6 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | -55 to 400 | 18" | 1/4" | ±0.12% | 10 | 1/2 | 316 Stainless Steel | 3" | 24 | 6 | Red/White | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded RTD Probe Transmitters with Digital Display for Liquids and Gas

4-Pole Micro M12 Plug-In Connection

Probe | Configurable Digital Output | Configurable Analog/Digital Output | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

RTD Probe Resistance, ohm | Temp. Range, ° F | Lg. | Dia. | Accuracy | Response Time, sec. | Probe Connection Pipe Size | Max. Pressure, psi | No. of | Communication Protocol | Signal Output | No. of | Current, mA | Signal Output | Overall Lg. | Fitting Material | Sensing Element Material | Specs. Met | Voltage, V DC | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NPT Male Probe Connection—Fixed 316L Stainless Steel Probe with Plastic Head (IP67) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 1/2" | 1/4" | ±0.75% | 3 | 1/4 | 5,800 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 4 7/8" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 1/2" | 1/4" | ±0.75% | 3 | 1/2 | 4,350 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 4 7/8" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 1 1/4" | 1/4" | ±0.75% | 3 | 1/4 | 5,800 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 5 5/8" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 1 1/4" | 1/4" | ±0.75% | 3 | 1/2 | 4,350 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 5 5/8" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 3 1/4" | 1/4" | ±0.75% | 3 | 1/2 | 3,625 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 7 5/8" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | -55 to 300 | 5 3/16" | 1/4" | ±0.75% | 3 | 1/2 | 3,625 | 1 | IO Link | NPN/PNP | 1 | 4 to 20 | NPN/PNP | 9 1/2" | 316L Stainless Steel | Platinum | EN 60751 Class A | 18 to 32 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||