About Selecting Temperature Sensors

More

RTD Probes for Liquids and Gases

Obtain more precise and reliable liquid and gas temperature measurements than thermocouple probes. Some of these probes meet DIN standards for accuracy, meaning they’re precise even with fast temperature changes.

IP67-rated probes have plug connections that stand up to dust and temporary submersion. IP68- and IP69K-rated probes have plug connections that can handle brief submersion and harsh washdowns.

For technical drawings and 3-D models, click on a part number.

Probes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Probe | Cables | ||||||||||

| RTD Type | Temperature Range, °F | Lg. | Dia. | Accuracy | Response Time, sec. | Environmental Rating | Specifications Met | Each | Each | ||

4-Pin Micro M12 Plug Connection—316L Stainless Steel Probe | |||||||||||

| 100 ohms | -40° to 300° | 2" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 0000000 | 0000000 | 000000 |

| 100 ohms | -40° to 300° | 2 3/4" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 3 7/8" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 5 7/8" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 6 1/4" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 7 7/8" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 9 7/8" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 10 1/4" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 13 3/4" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 14 1/8" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 100 ohms | -40° to 300° | 22" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 6 1/4" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 6 1/4" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 10 1/4" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 10 1/4" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 14 1/8" | 1/4" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 14 1/8" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | -40° to 300° | 22" | 3/8" | ±0.1% | 3 | IP68, IP69K | DIN EN 60751 Class A | 0000000 | 000000 | 0000000 | 00000 |

Probe | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temperature Range, °F | Lg. | Dia. | Accuracy | Response Time, sec. | Cable Length | Max. Cable Temperature, °F | Environmental Rating | Specifications Met | Each | |

4-Pin Micro M12 Plug Connection—316 Stainless Steel Probe | |||||||||||

| 100 ohms | -145° to 1110° | 3 7/8" | 1/4" | ±0.1% | 34 | 6.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 0000000 |

| 100 ohms | -145° to 1110° | 5 7/8" | 1/4" | ±0.1% | 34 | 6.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -145° to 1110° | 7 7/8" | 1/4" | ±0.1% | 34 | 6.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -145° to 1110° | 7 7/8" | 1/4" | ±0.1% | 34 | 32 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -145° to 1110° | 9 7/8" | 1/4" | ±0.1% | 34 | 6.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 1,000 ohms | -55° to 480° | 2" | 1/4" | ±0.1% | 37 | 0.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

4-Pin Micro M12 Plug Connection—316L Stainless Steel Probe | |||||||||||

| 100 ohms | -55° to 480° | 1 5/8" | 3/8" | ±0.1% | 39 | 6.5 ft. | 480° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -40° to 190° | 1 3/4" | 1/4" | ±0.1% | 10 | 6.5 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -40° to 190° | 1 3/4" | 1/4" | ±0.1% | 10 | 16 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -40° to 190° | 2" | 3/8" | ±0.1% | 25 | 6.5 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 100 ohms | -40° to 190° | 2" | 3/8" | ±0.1% | 25 | 16 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| 1,000 ohms | -40° to 190° | 1 3/4" | 1/4" | ±0.1% | 10 | 6.5 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 00000 |

| 1,000 ohms | -40° to 190° | 2" | 3/8" | ±0.1% | 25 | 6.5 ft. | 190° | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

Bolt-On RTD Probes for Surfaces

For reliable temperature readings in high-vibration environments, these RTD probes bolt onto the surface of motors and other equipment.

Style A and B probes are rated IP67 for protection from dust and temporary submersion.

Probes that meet DIN EN 60751 adhere to industry standards for accuracy. Probes that meet MS202 (Method 204, Test Condition D) have been tested for use in vibration-heavy environments.

Probe | Cable | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Environmental Rating | Specifications Met | Each | |

Stainless Steel Probe | ||||||||||||||

| A | 100 ohms | -40° to 190° | 1/2" | 2" | 7/16" | 5/16" | ±0.5% | 15 | 6 | Polyurethane Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 0000000 |

Probe | Cable | Wire Lead | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Environmental Rating | Specifications Met | Each | |

Stainless Steel Probe | |||||||||||||||||

| B | 100 ohms | -40° to 190° | 1/4" | 1 13/16" | 7/16" | 5/16" | ±0.5% | 39 | 6 | Polyurethane Rubber | 1" | 22 | 4 | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

Probe | Cable | Wire Lead | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Specifications Met | Fasteners Included | Each | |

303 Stainless Steel Probe | |||||||||||||||||

| C | 100 ohms | -55° to 500° | 5/32" | 3/8" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 0000000 |

316/316L Stainless Steel Probe | |||||||||||||||||

| D | 100 ohms | -90° to 930° | 5/32" | 1 1/4" | 5/16" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

300 Series Stainless Steel Probe | |||||||||||||||||

| E | 100 ohms | -90° to 930° | 5/32" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

Nickel-Plated Copper Probe | |||||||||||||||||

| F | 100 ohms | -55° to 500° | 17/64" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

Adhesive-Back RTD Probes for Surfaces

About the thickness of a dime, these RTD probes stick to surfaces in tight spaces to measure temperature.

Probes that meet DIN EN 60751 adhere to industry standards for accuracy. Probes that meet MIL-STD-108 are submersible, so they can monitor the temperature of water in tanks or containers.

Probe | Cable | Wire Lead | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Specifications Met | Each | |

Wire Leads Connection—Platinum Probe | ||||||||||||||

| 100 ohms | -4° to 300° | 9/16" | 3/16" | 1/16" | ±0.12% | 1.3 | 3 | Silicone Rubber | 1/2" | 28 | 3 | DIN EN 60751 Class B; MIL-STD-108 | 0000000 | 0000000 |

| 100 ohms | -4° to 350° | 1/4" | 1/4" | 1/16" | ±0.12% | 0.15 | 3 | PTFE | 1/2" | 28 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 5/8" | 3/16" | 1/16" | ±0.12% | 0.4 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 5/8" | 3/16" | 1/16" | ±0.12% | 1 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 5/8" | 5/16" | 1/16" | ±0.12% | 1.2 | 3 | PTFE | 1/2" | 22 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 13/16" | 3/8" | 1/16" | ±0.12% | 0.9 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 1 1/4" | 1" | 1/16" | ±0.12% | 0.2 | 3 | Silicone Rubber | 1/2" | 24 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

| 100 ohms | -4° to 350° | 1 15/16" | 3/4" | 1/16" | ±0.12% | 0.1 | 3 | PTFE | 1/2" | 24 | 3 | DIN EN 60751 Class B | 0000000 | 000000 |

Threaded RTD Probes for Surfaces

Thread these RTD probes into threaded holes in molds, dies, and other objects to measure their temperature.

Style A and B probes are rated IP67 for protection from dust and temporary submersion.

Probes that meet DIN EN 60751 adhere to industry standards for accuracy. Probes that meet MS202 (Method 204, Test Condition D) have been tested for use in vibration-heavy environments.

Thread | Probe | Cable | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Size | Pitch, mm | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Environmental Rating | Specifications Met | Each | ||

Stainless Steel Probe | |||||||||||||||

| A | 100 ohms | -20° to 350° | M5 | 0.8 | 15/16" | 5/16" | 3/16" | ±0.5% | 8 | 6 | Silicone Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 0000000 |

| A | 100 ohms | -20° to 350° | M6 | 1 | 15/16" | 5/16" | 3/16" | ±0.5% | 8 | 6 | Silicone Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| A | 100 ohms | -40° to 190° | M5 | 0.8 | 15/16" | 5/16" | 3/16" | ±0.5% | 8 | 6 | Polyurethane Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

| A | 100 ohms | -40° to 190° | M6 | 1 | 15/16" | 5/16" | 3/16" | ±0.5% | 9 | 6 | Polyurethane Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

Thread | Probe | Cable | Wire Lead | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Size | Pitch, mm | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Environmental Rating | Specifications Met | Each | ||

Stainless Steel Probe | ||||||||||||||||||

| B | 100 ohms | -20° to 300° | M12 | 1.5 | 1 3/16" | 3/8" | 11/16" | ±0.5% | 12 | 16 | Silicone Rubber | 1" | 22 | 4 | IP67 | DIN EN 60751 Class A | 0000000 | 0000000 |

Probe | Cable | Wire Lead | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Thread Size | Lg. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Specifications Met | Each | ||

303 Stainless Steel Probe | ||||||||||||||

| C | 100 ohms | -55° to 500° | 1/4"-20 | 3/8" | ±0.12% | 10 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | 0000000 | 0000000 |

Signal-Averaging Adhesive-Back RTD Probes for Surfaces

Measure the temperature of cylinders, pipes, and flat surfaces without installing an immersion probe and where a point sensor may be inaccurate. These RTD probes take multiple temperatures along the length of the probe and average them together for accuracy. About the thickness of a dime, they stick to surfaces in tight spaces.

Probes that meet DIN EN 60751 adhere to industry standards for accuracy.

Probe | Cable | Wire Lead | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Specifications Met | Each | ||

Wire Leads Connection—Platinum Probe | |||||||||||||||

| B | 100 ohms | -4° to 350° | 4" | 3/8" | 1/16" | ±0.12% | 0.6 | 3 | Silicone Rubber | 1/2" | 26 | 3 | DIN EN 60751 Class B | 0000000 | 0000000 |

Threaded RTD Probe Transmitters for Liquids and Gases

Send temperature readings directly to programmable logic controllers (PLCs)—with a built-in 4-20mA transmitter, these RTDs don’t require a separate signal converter. They have an NPT male probe connection, so they’re ready to screw into thermowells and other fittings on pipe and tanks. Made of 316 or 316L stainless steel, they resist corroding from harsh cleaning chemicals. This stainless steel also protects the RTD sensor inside from impact. They are also often installed in bores to measure the temperature of molds and dies. CE marked, they meet European safety standards.

Fixed RTDs can be used directly in liquid or steam because they’re welded to their fitting for a liquid-tight seal.

RTDs with IO Link let you remotely adjust settings, read measurements, and receive error messages when connected to a PLC via an IO Link controller (not included). These RTDs meet DIN EN 60751 Class A standards for temperature accuracy. UL and C-UL listed, they meet American and Canadian safety standards.

For technical drawings and 3-D models, click on a part number.

Probe Transmitters | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Probe | Probe Connection | Cables with Socket | ||||||||||||||||

| RTD Type | Lg. | Dia. | Accuracy | Response Time, sec. | Pipe Size | Thread Type | Gender | DC Voltage | Max. Pressure, psi | Output Current | Communication Protocol | Overall Lg. | Fitting Material | Temp. Range, °F | Each | Each | ||

Fixed 316L Stainless Steel Probe (IP67, IP68, IP69K) | ||||||||||||||||||

| 1,000 ohms | 11/16" | 1/4" | ±0.5% | 3 | 1/2 | NPT | Male | 18-32 | 5,800 | 4-20mA | IO Link | 4 1/8" | 316L Stainless Steel | 0° to 300° | 0000000 | 0000000 | 0000000 | 000000 |

| 1,000 ohms | 1 1/2" | 1/4" | ±0.5% | 3 | 1/2 | NPT | Male | 18-32 | 4,350 | 4-20mA | IO Link | 5" | 316L Stainless Steel | 0° to 300° | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | 3 1/2" | 1/4" | ±0.5% | 3 | 1/2 | NPT | Male | 18-32 | 4,350 | 4-20mA | IO Link | 7" | 316L Stainless Steel | 0° to 300° | 0000000 | 000000 | 0000000 | 00000 |

| 1,000 ohms | 5 7/16" | 1/4" | ±0.5% | 3 | 1/2 | NPT | Male | 18-32 | 4,350 | 4-20mA | IO Link | 8 7/8" | 316L Stainless Steel | 0° to 300° | 0000000 | 000000 | 0000000 | 00000 |

Threaded RTD Probe Transmitters with Digital Display for Liquids and Gases

View temperature readings and adjust settings directly on these RTD probe transmitters. To communicate with programmable logic controllers (PLCs), they have a built-in transmitter with two outputs. One output can send a digital switching signal or use IO Link protocol with the addition of an IO Link controller (not included). The other can send a digital switching signal or a 4-20mA analog signal. The different output options make these RTDs good for a wide range of uses, including operating far away from a controller, taking automated measurements, and providing inputs to switching applications. All have an NPT threaded fitting welded onto the probe, so they’re ready to screw into containers, tanks, and pipes. Probe length is fixed. Made of 316L stainless steel, they are highly corrosion resistant.

These RTDs meet DIN EN 60751 Class A standards for temperature accuracy. UL Listed, C-UL Listed, and CE Marked, all meet American, Canadian, and European safety standards.

For technical drawings and 3-D models, click on a part number.

Probe | Configurable Digital Output | Configurable Analog/Digital Output | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temp. Range, °F | Lg. | Dia. | Accuracy | Response Time, sec. | Plug Type | Probe Connection Pipe Size | Max. Pressure, psi | No. of | Communication Protocol | Signal Type | No. of | Current | Signal Type | Overall Lg. | Each | |

NPT Male Probe Connection | |||||||||||||||||

316L Stainless Steel Probe with Plastic Head (IP67) | |||||||||||||||||

| 1,000 ohms | -55° to 300° | 1/2" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/4 | 5,800 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 4 7/8" | 0000000 | 0000000 |

| 1,000 ohms | -55° to 300° | 1/2" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/2 | 4,350 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 4 7/8" | 0000000 | 000000 |

| 1,000 ohms | -55° to 300° | 1 1/4" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/4 | 5,800 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 5 5/8" | 0000000 | 000000 |

| 1,000 ohms | -55° to 300° | 1 1/4" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/2 | 4,350 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 5 5/8" | 0000000 | 000000 |

| 1,000 ohms | -55° to 300° | 3 1/4" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/2 | 3,625 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 7 5/8" | 0000000 | 000000 |

| 1,000 ohms | -55° to 300° | 5 3/16" | 1/4" | ±0.75% | 3 | 4-Pole Micro M12 | 1/2 | 3,625 | 1 | IO Link | NPN/PNP | 1 | 4-20mA | NPN/PNP | 9 1/2" | 0000000 | 000000 |

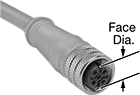

| Cable Lead Lg., ft. | Voltage | Current | Face Diameter | Each | |

| 12 | 250V AC/250V DC | 4A | 0.3" | 0000000 | 000000 |

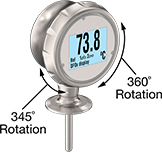

Sanitary RTD Probe Transmitters with Digital Display for Liquids and Gases

Check the temperature of liquids in hygienic applications such as food or pharmaceutical lines and tanks. Certified by 3-A to meet sanitary design standards, the parts of these probes that will touch liquid are highly polished to minimize spots where bacteria could grow. They're made of stainless steel, so they won't corrode from harsh cleaners and sanitizers. The housing is IP69K rated, meaning it withstands high-pressure, high-temperature washdowns that are common in hygienic cleaning practices. They have a flange that will connect to sanitary quick-clamp fittings (also known as tri-clamp fittings); they're easy to connect and remove from your line.

Program these probes with the touch screen, and select one of three colors as a visual alert for events in your process such as irregular or fluctuating temperatures. The head swivels 345° and the face rotates all the way around, so you can mount the sensor at any angle and still see the display. To trigger actions in your process line, connect these probes to remote displays, programmable logic controllers (PLCs), and other control equipment with the M12 plug. These probes meet DIN EN 60751, an industry standard for accuracy. They’re also CE marked, meaning they meet European Union safety standards.

For technical drawings and 3-D models, click on a part number.

Probe | Probe Transmitters | Cables with Socket | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RTD Type | Temperature Range, °F | Lg. | Dia. | Flange OD | Accuracy | Response Time, sec. | Plug Type | DC Voltage | Max. Pressure, psi | Output Current | Overall Lg. | Each | Each | ||

316L Stainless Steel Probe with 304 Stainless Steel Head (IP69K) | |||||||||||||||

For 1 1/2" Tube OD | |||||||||||||||

| 100 ohms | -55° to 480° | 2" | 5/16" | 1.988" | ±0.1% | 25 | 5-Pole Micro M12 | 8-35 | 580 | 4-20mA | 6 3/4" | 0000000 | 0000000 | 0000000 | 000000 |