Filter by

Material

Volume

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Quick-Set Casting Compounds

|

Create detailed rubber shapes that are ready to use in fifteen minutes or less. Unlike traditional casting compounds, which can take up to 24 hours to set, these compounds harden after two minutes, and can be removed from molds within fifteen. Use them to make your own prototypes, molds, and linings.

Casting Compounds

|

Silicone Rubber |

Soft—Soft silicone rubber is more flexible and easier to peel off of molds than hard silicone rubber, especially when making complex shapes.

Hard— Hard silicone rubber holds its shape better than soft silicone rubber, so small ridges and channels are less likely to collapse or deform while making molds.

69° F Cure Temperature—Combine acrylic plastic or silicone rubber with a 69° cure temperature compounds in different ratios to adjust the consistency from thin to thick. Thin mixtures are easier to pour and better for filling small crevices.

70° F Cure Temperature—Silicone rubber with a 70° cure temperature compounds are a putty that you can mix with your hands and form into any shape. Press an object into these compounds to create a mold for casting duplicates. They do not shrink as they dry, so textures and other fine details are captured faithfully.

Hardness | Time to Harden, min. | Time to Cure, min. | Time to Demold, min. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 4 | 0.2 | 8595K15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 46 | 2.2 | 8595K14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 8 | 0.5 | 5166N14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 23 | 1.1 | 5166N15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 4 | 0.2 | 8595K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 46 | 2.2 | 8595K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 13 | 0.8 | 5166N16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 32 | 1.75 | 5166N17 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

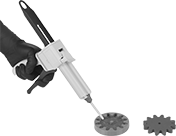

Casting Compounds with Dispensing Gun

|

Compounds with dispensing gun come ready to use—no mixing required—and won’t leave a mess.

Hard— Hard silicone rubber holds its shape better than soft silicone rubber, so small ridges and channels are less likely to collapse or deform while making molds.

Soft—Soft silicone rubber is more flexible and easier to peel off of molds than hard silicone rubber, especially when making complex shapes.

69° F Cure Temperature—Combine acrylic plastic or silicone rubber with a 69° cure temperature compounds in different ratios to adjust the consistency from thin to thick. Thin mixtures are easier to pour and better for filling small crevices.

Hardness Rating | Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Wt., lb. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft | Durometer 30A | 2 | 10 min. | 10 min. | 69 | 250 | 0% | Green | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 5166N13 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft Hard | Durometer 30A Durometer 55A | 2 | 10 min. 6 min. | 10 min. 6 min. | 69 | 250 | 0% | Green Orange | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 5166N12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hard | Durometer 55A | 2 | 6 min. | 6 min. | 69 | 250 | 0% | Orange | No | 4 | 15 Disposable Nozzles, 2 Snap-On Nozzles, Carrying Case, Six each 3 cu. in. Disposable Cartridges | 5166N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant Casting Compounds

|

This silicone rubber compound offers good resistance to acids, oils and salt water. Use it to capture intricate details when creating prototypes, molds, and linings with this easy-to-mix two-part compound. It is a durable and tear-resistant silicone rubber, which easily demolds.

View our selection of release agents.

Long-Life Casting Compounds

|

Create rubber molds that retain their shape for decades—they won’t soften, degrade, or warp, so you can continue to replicate intricate parts. Because these compounds don’t shrink as they cure, they are more accurate and predictable than other compounds.

View our selection of release agents.

Hardness | Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Urethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 45A | 60 | 24 | 16 | 77 | 200 | 0% | Yellow | Yes | 58 | 2.2 | 4353N11 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

See-Through Casting Compounds

|

Create transparent molds to monitor fill levels, differentiate parts at a glance, and avoid damaging parts when cutting the mold away. These casting compounds are two parts that activate when mixed.

View our selection of release agents.

Silicone Rubber—Silicone rubber compounds handle higher temperatures than urethane rubber compounds—up to 570° F. Silicone rubber also cures faster than urethane rubber, and it won't shrink as it cures, which means you won't need to guess at the final size of your mold. Because silicone rubber compounds trap air bubbles when mixed, they must be cured inside a vacuum chamber. The chamber removes the trapped air bubbles, strengthens the mold, and improves its clarity.

Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp. | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 10 | 1.5 hr. 30 min. | 1.5 hr. 30 min. | 77° F 120° F | 570 | 0% | Blue | Yes | 57 | 2.2 | 8644K63 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||