Filter by

Performance

Volume

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Quick-Set Casting Compounds

Casting Compounds

Hardness | Time to Harden, min. | Time to Cure, min. | Time to Demold, min. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Soft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 4 | 0.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 27A | 2 | 15 | 15 | 70 | 650 | 0% | Light Blue | Yes | 46 | 2.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 8 | 0.5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 30A | 2 | 10 | 10 | 69 | 250 | 0% | Green | Yes | 23 | 1.1 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 4 | 0.2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 2 | 15 | 15 | 70 | 600 | 0% | Green | Yes | 46 | 2.2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 13 | 0.8 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 50A | 2 | 10 | 10 | 69 | 250 | 0% | Light Blue | Yes | 32 | 1.75 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

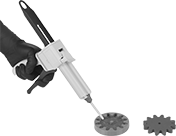

Casting Compounds with Dispensing Gun

Hardness Rating | Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Wt., lb. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft | Durometer 30A | 2 | 10 min. | 10 min. | 69 | 250 | 0% | Green | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Soft Medium | Durometer 30A Durometer 55A | 2 | 10 min. 6 min. | 10 min. 6 min. | 69 | 250 | 0% | Green Orange | No | 4 | Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Medium | Durometer 55A | 2 | 6 min. | 6 min. | 69 | 250 | 0% | Orange | No | 4 | 15 Disposable Nozzles, 2 Snap-On Nozzles, Carrying Case, Six each 3 cu. in. Disposable Cartridges | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant Casting Compounds

See-Through Casting Compounds

Hardness | Time to Harden, min. | Time to Cure | Time to Demold | Cure Temp. | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicone Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Durometer 40A | 10 | 1.5 hr. 30 min. | 1.5 hr. 30 min. | 77° F 120° F | 570 | 0% | Blue | Yes | 57 | 2.2 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Casting Compounds

Time to Harden, min. | Time to Cure, hr. | Time to Demold, hr. | Cure Temp., ° F | Max. Temp., ° F | Shrinkage | Color | Mixing Req. | Volume, cu. in. | Wt., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Silicon Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.5% | Black | Yes | 47 | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.5% | Black | Yes | 119 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silica | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.3% | White | Yes | 62 | 4 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 24 | 24 | 77 | 2,700 | 1.3% | White | Yes | 155 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||