Filter by

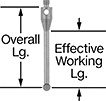

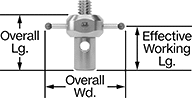

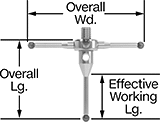

Overall Length

Stem Material

Effective Working Length

End Material

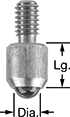

Stem Diameter

Manufacturer Model Number

Length

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Dial Indicator Size

Probe Styli

Ruby Ball-End Styli

Material | Ball | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

End Dia., mm | Effective Working Lg., mm | Overall Lg., mm | Stem Dia., mm | Stem | Body | End Dia. Tolerance, mm | Precision Grade | Sphericity Tolerance, mm | Mfr. | Mfr. Model No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3 | 2 | 10 | 0.2 | Tungsten Carbide | Stainless Steel | -0.00025 to 0.00025 | 10 | -0.00025 to 0.00025 | Renishaw | A-5000-7800 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3 | 2 | 20 | 0.2 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5004-7398 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 3 | 10 | 0.4 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7805 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 7 | 20 | 0.3 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-1345 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | 4 | 10 | 0.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7801 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.7 | 12 | 20 | 0.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0577 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4.5 | 10 | 0.7 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7806 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 7 | 20 | 0.7 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7808 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 12.5 | 20 | 0.8 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0033 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 20.5 | 27.5 | 0.7 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-8663 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 4.5 | 10 | 0.7 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7802 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 12.5 | 20 | 1 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0034 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 22.5 | 30 | 1 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0035 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 6 | 10 | 1 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7807 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 14 | 20 | 1 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-3822 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 14 | 20 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3603 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 22.5 | 30 | 1.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0036 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 32.5 | 40 | 1.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0037 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 6.5 | 10 | 1 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7803 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 16.4 | 20 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7804 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 32.7 | 40.2 | 2 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0039 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 7 | 10 | 1.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3604 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 17 | 20 | 1.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-4160 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 47 | 50 | 2 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0064 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 10 | 10 | 1.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-4154 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 20 | 20 | 1.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-4161 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 50 | 50 | 2 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0065 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 20 | 20 | 2.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0046 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 30 | 30 | 2.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-4779 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 50 | 50 | 2.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0066 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 10 | 10 | 2.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-4156 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 30 | 30 | 2.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-4780 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 50 | 50 | 2.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0470 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 11 | 11 | 2.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-4158 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M3 × 0.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4 | 21 | 0.7 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3551 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 22.5 | 30 | 1 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0051 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 9.6 | 21 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3552 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 32.5 | 40 | 1.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0053 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14.7 | 21 | 1.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3553 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 75 | 75 | 4 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-7057 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 100 | 100 | 4 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-7445 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4.5 | 19.5 | 0.7 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7545 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 8.9 | 19 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7547 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 40 | 50 | 1.5 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-4797 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 38.5 | 50 | 2 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-3680 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 13.7 | 18 | 3 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7551 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 33.5 | 50 | 3 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0233 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 16 | 20 | 3 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-6731 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 26 | 30 | 3 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-6352 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 58.5 | 75 | 3.8 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0236 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 83.2 | 100 | 4.5 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7522 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 83.5 | 100 | 3.8 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-9761 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 33.4 | 50 | 4.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3709 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 38.5 | 50 | 4.5 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-7306 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 88.5 | 100 | 4.4 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-6510 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 88.5 | 100 | 4.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3712 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 88.5 | 100 | 4.5 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-1358 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 135 | 150 | 4.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-8156 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 188.5 | 200 | 4.5 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-6512 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 50 | 50 | 4.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7795 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 100 | 100 | 4.5 | Ceramic | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7796 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 300 | 300 | 4.4 | Carbon Fiber | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-3461 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ruby Ball/Star-End Styli

Material | Ball | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Styli | End Dia., mm | Effective Working Lg., mm | Overall Lg., mm | Overall Wd., mm | Stem Dia., mm | Stem | Body | End Dia. Tolerance, mm | Precision Grade | Sphericity Tolerance, mm | Mfr. | Mfr. Model No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 | 2.5 | 3 | 10 | 0.7 | Tungsten Carbide | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7811 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2 | 12 | 19.3 | 18 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7629 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2 | 12 | 19.3 | 30 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-3626 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M3 × 0.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 2 | 12 | 21.5 | 30 | 1.4 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5003-0076 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Probe Styli Kits

|

No. of Pieces | Includes | Container Type | Body Material | Mfr. | Mfr. Model No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ruby End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | One 0.5 mm Dia. Ruby Ball Stylus with Tungsten Carbide Stem—10 mm O'all Lg. (3 mm EWL) One 1 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—10 mm O'all Lg. (4.5 mm EWL) Two 1 mm Dia. Ruby Ball Styli with Tungsten Carbide Stem—20 mm O'all Lg. (12.5 mm EWL) Two 2 mm Dia. Ruby Ball Styli with Stainless Steel Stem—20 mm O'all Lg. (14 mm EWL) One 3 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—20 mm O'all Lg. (17 mm EWL) One 4 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—20 mm O'all Lg. (20 mm EWL) One 10 mm Lg. Stylus Extension One 20 mm Lg. Stylus Extension Two Stylus Installation Tools | Plastic Case | Stainless Steel | Renishaw | A-5004-5131 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M3 × 0.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Carbon Steel End, Ruby End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | One 1 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—21 mm O'all Lg. (4 mm EWL) One 2 mm Dia. Ruby Ball Stylus with Tungsten Carbide Stem—40 mm O'all Lg. (32.5 mm EWL) One 3 mm Dia. Ruby Ball Stylus with Tungsten Carbide Stem—50 mm O'all Lg. (43.7 mm EWL) One 4 mm Dia. Ruby Ball Stylus with Tungsten Carbide Stem—40 mm O'all Lg. (36 mm EWL) One 5 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—21 mm O'all Lg. (21 mm EWL) One 5 mm Dia. Ruby Ball Stylus with Ceramic Stem—50 mm O'all Lg. (50 mm EWL) One 35 mm Dia. × 5 mm Thick. High-Carbon Steel Disc Stylus One 50 mm Lg. Stylus Extension Two Stylus Installation Tools | Plastic Case | Stainless Steel | Renishaw | A-5004-6880 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ruby End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | One 1 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—19.5 mm O'all Lg. (4.5 mm EWL) One 2 mm Dia. Ruby Ball Stylus with Stainless Steel Stem—19 mm O'all Lg. (8.9 mm EWL) Two 6 mm Dia. Ruby Ball Styli with Ceramic Stem—50 mm O'all Lg. (33.4 mm EWL) Two 6 mm Dia. Ruby Ball Styli with Ceramic Stem—100 mm O'all Lg. (88.5 mm EWL) Two 30 mm Lg. Stylus Extensions Two 12 mm Lg. Break Stems Two Stylus Installation Tools One Wrench | Plastic Case | Stainless Steel | Renishaw | A-5004-5132 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Contact Points for Plunger Variance Indicators

Ball Contact Points

Dia., mm | Lg. | Precision Ball Grade | Sphericity Tolerance | Mounting Thread Size | Body Material | For Dial Indicator Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ruby | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/4" | 25 | -0.000025" to 0.000025" | 4-48 | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/4" | 25 | -0.000025" to 0.000025" | M2.5 × 0.45 mm | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/2" | 25 | -0.000025" to 0.000025" | 4-48 | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/4" | 25 | -0.000025" to 0.000025" | 4-48 | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/2" | 25 | -0.000025" to 0.000025" | 4-48 | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3/4" | 25 | -0.000025" to 0.000025" | 4-48 | Stainless Steel | AGD Group 0, AGD Group 1, AGD Group 2, AGD Group 3, AGD Group 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Probe Styli for Thin Materials

Ruby Cylindrical-End Styli

Material | Ball | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

End Dia., mm | Effective Working Lg., mm | Overall Lg., mm | Stem Dia., mm | Stem | Body | End Dia. Tolerance, mm | Precision Grade | Sphericity Tolerance, mm | Mfr. | Mfr. Model No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M2 × 0.4 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Tip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 8 | 15 | 1 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-8876 | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 7.2 | 21.2 | 1.6 | Stainless Steel | Stainless Steel | -0.00013 to 0.00013 | 5 | -0.00013 to 0.00013 | Renishaw | A-5000-7812 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||