About Sanding Abrasives

More

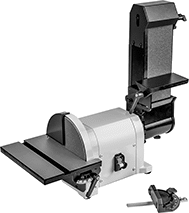

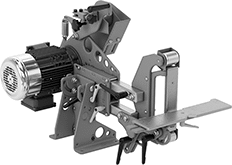

Combination Disc and Belt Sanders

Versatile enough to handle both detail work and heavy material removal, these are a disc and belt sander in one. The disc sander smooths edges, while the belt sander removes a lot of material on large surfaces. Adjustable belt tracking lets you maintain proper tension. Sanders with two voltages are wired for the lower voltage listed.

Dust-collecting sanders remove particles from the air and surface of the disc and belt to extend their life. They have a port that connects to a dust collector or vacuum system.

Sanders with a variable-speed motor let you set the speed for any task, so you can switch between materials or adjust for aggressive and fine sanding.

Sanders with a miter gauge make it easy to sand angles.

Sanders with a belt-release lever enable you to quickly swap out your belt.

Sanders with a detachable platen make it easy to sand contours.

For Adhesive-Back Disc | For Belt | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Dia. | Table Wd. | Table Lg. | Max. No-Load Speed, rpm | Wd. | Lg. | Orientation | Table Wd. | Table Lg. | Max. No-Load Speed, sfpm | Voltage | Current, A | Motor Speed, rpm | Features | Each | |

Variable Speed | ||||||||||||||||

Three-Prong Plug (Single Phase) with Miter Gauge | ||||||||||||||||

| 1 1/2 | 12" | 9" | 16" | 2,400 | 2" | 72" | Horizontal and Vertical | 2" | 6" | 6,250 | 120V AC 240V AC | 14 7 | 1,800 | Adjustable Belt Tracking, Belt Guard, Detachable Platen, Belt-Release Lever | 00000000 | 000000000 |

For Adhesive-Back Disc | For Belt | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Dia. | Table Wd. | Table Lg. | Max. No-Load Speed, rpm | Wd. | Lg. | Orientation | Table Wd. | Table Lg. | Max. No-Load Speed, sfpm | Voltage | Current, A | Motor Speed, rpm | Features | Each | |

One Speed | ||||||||||||||||

Three-Prong Plug (Single Phase) | ||||||||||||||||

| 1/2 | 10" | 6" | 11" | 1,725 | 4" | 36" | Horizontal and Vertical | 2 1/2" | 5" | 1,800 | 120V AC 240V AC | 7.4 3.7 | 1,725 | Adjustable Belt Tracking, Dust Extraction Port | 0000000 | 000000000 |

Three-Prong Plug (Single Phase) with One-Piece Steel Stand | ||||||||||||||||

| 3 | 12" | 8" | 14" | 2,500 | 6" | 48" | Horizontal and Vertical | 6" | 10" | 2,800 | 240V AC | 12 | 1,725 | Adjustable Belt Tracking, Dust Extraction Port, Belt Guard, Detachable Platen | 0000000 | 00000000 |

Variable Speed | ||||||||||||||||

Three-Prong Plug (Single Phase) with Miter Gauge and One-Piece Steel Stand | ||||||||||||||||

| 2 | 14" | 7 1/4" | 15 1/2" | 1,775 | 6" | 48" | Any Angle and Horizontal and Vertical | 6" | 8 1/2" | 2,250 | 120V AC 240V AC | 12.5 6.2 | 1,720 | Adjustable Belt Tracking, Dust Extraction Port, Belt Guard, Detachable Platen | 00000000 | 00000000 |

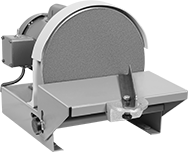

Light-Duty Combination Disc and Belt Sanders

Compact and lightweight, these combination sanders are best for small projects and touch-ups. The disc sander smooths edges on small features, while the belt sander removes more material over a larger surface area. The belt on these sanders tilts, so you can use it horizontally or vertically. Use the miter gauge to position your workpiece on the table, so you can sand at an angle. These sanders also have a port that connect to a dust collector or vacuum system. This removes particles from the air and the surface of the disc and belt to extend their life. A belt-release lever enables you to quickly swap out your belt. Use them with sanding belts and adhesive-back sanding discs.

Sanders with a detachable platen make it easy to sand contours.

For Adhesive-Back Disc | For Belt | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| hp | Dia. | Table Wd. | Table Lg. | Max. No-Load Speed, rpm | Wd. | Lg. | Table Wd. | Table Lg. | Max. No-Load Speed, sfpm | Voltage | Current, A | Motor Speed, rpm | Phase | Includes | Features | Each | |

| 1/3 | 6" | 6" | 8" | 3,500 | 1", 2" | 42" | 6 3/4" | 9" | 4,400 | 120V AC | 3.5 | 3,550 | Single | Miter Gauge | Belt-Release Lever, Detachable Platen, Dust Extraction Port | 00000000 | 0000000 |

| 3/4 | 8" | 6" | 10" | 3,550 | 4" | 36" | 3" | 6" | 2,150 | 120V AC | 5 | 3,550 | Single | Miter Gauge | Belt-Release Lever, Dust Extraction Port | 00000000 | 000000 |

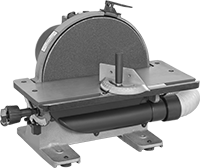

Stationary Disc Sanders

Use with adhesive-back discs. Sanders with two voltages are wired for the lower voltage.

Sanders with lever control have a built-in dust fan with a hose that attaches to any standard shop vacuum.

Miter gauge enables angled sanding.

Table | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Disc Dia. | Wd. | Lg. | Max. No-Load Speed, rpm | No. of Speeds | Voltage | Current, A | Motor Type | Motor Speed, rpm | hp | Phase | Includes | Features | Each | |

Lever Control | ||||||||||||||

| 12" | 6 1/4" | 17 1/4" | 1,725 | One | 120V AC | 6 | Brushed | 1,725 | 1/2 | Single | __ | Built-In Dust Fan | 0000000 | 0000000 |

On/Off Switch Control | ||||||||||||||

| 10" | 6" | 11" | 1,725 | One | 120V AC/240V AC | 7.4/3.7 | Brushed | 1,725 | 1/2 | Single | Miter Gauge | Disc Guard | 0000000 | 000000 |

| 12" | 8" | 14" | 1,725 | One | 120V AC/240V AC | 12.8/6.4 | Brushed | 1,725 | 1 | Single | Miter Gauge | Disc Guard | 0000000 | 00000000 |

| Optional Miter Gauge for Lever-Control Sander | 0000000 | Each | 000000 |

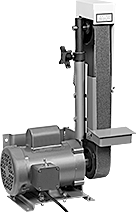

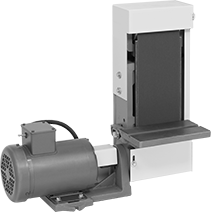

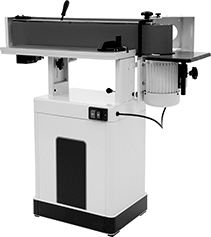

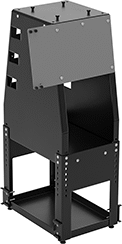

Stationary Belt Sanders with Dust Collector

Mounted on a 100 cfm dust collector, this sander operates in a horizontal and vertical position. The adjustable belt tracking lets you maintain proper belt tension. Sander is wired for the lower voltage listed. Sanding belts are sold separately.

For Belt | Table | Dust Collector | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Lg. | Wd. | Lg. | Max. No-Load Speed, sfpm | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Ht. | Wd. | Dp. | Each | |

| 4" | 36" | 2 1/2" | 5" | 3,615 | One | 120V AC/240V AC | 7/3.5 | 3,450 | 1/2 | Single | 32" | 14" | 12" | 0000000 | 000000000 |

Stationary Belt Sanders

The adjustable belt tracking lets you maintain proper belt tension. These sanders are wired for the lower voltage listed. Sanding belts are sold separately.

Sander for 2” wide belts has a full-length hinge on the belt guard that allows easy access to the belt.

Detachable platen enables contour sanding.

For Belt | Table | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Lg. | Orientation | Wd. | Lg. | Max. No-Load Speed, sfpm | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Includes | Features | Each | |

| 1" | 42" | Vertical | 3" | 3" | 1,800 | One | 120V AC 240V AC | 5.4 2.7 | 1,725 | 1/3 | Single | Contact Wheel | Adjustable Belt Tracking, Belt Guard, Detachable Platen | 0000000 | 0000000 |

| 2" | 48" | Horizontal and Vertical | 2 1/2" | 5" | 4,500 | One | 120V AC 240V AC | 7 3.5 | 3,450 | 1/2 | Single | Contact Wheel | Adjustable Belt Tracking, Belt Guard, Detachable Platen | 00000000 | 000000 |

| 4" | 36" | Horizontal and Vertical | 2 1/2" | 5" | 3,600 | One | 120V AC 240V AC | 7 3.5 | 3,450 | 1/2 | Single | __ | Adjustable Belt Tracking, Belt Guard | 0000000 | 000000 |

| Optional Floor Stand | 0000000 | Each | 0000000 |

Any-Angle Stationary Belt Sanders

Sander |  Optional Floor Stand |  Replacement Motor |  Replacement Coupling Assembly | ||

Replacement Idler Spindle Assembly |  Replacement Drive Pulley | ||||

Operate these sanders in a horizontal position, vertical position, or any angle in between. The adjustable belt tracking lets you maintain proper belt tension. Sanding belts are sold separately.

For Belt | Table | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Lg. | Wd. | Lg. | Max. No-Load Speed, sfpm | No. of Speeds | Voltage | Current, A | Motor Type | Motor Speed, rpm | hp | Features | Each | |

| 6" | 48" | 6" | 10" | 3,500 | One | 120V AC/240V AC | 24/12 | Brushed | 3,450 | 3 | Adjustable Belt Tracking, Belt Guard | 0000000 | 000000000 |

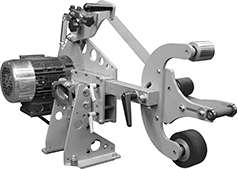

Oscillating Any-Angle Stationary Belt Sanders

For even wear across the sanding belt, these sanders move the belt up and down as it rotates. This dual motion reduces clogs, prevents overheating, and makes the belt last longer. The backing plate behind the belt has a graphite coating to reduce heat further. Position these sanders at the angle you need to best access your workpiece. Set the belt flat to sand long, flat surfaces or at a 90° angle to sand edges. It can also be tilted to any angle in between for beveling. To finish contoured surfaces, press your material against the outer drum.

These sanders have adjustable belt tracking, which lets you maintain proper belt tension. For quick belt changes, there’s a belt-release lever. If you want to connect them to a dust collector or vacuum system, they have a dust extraction port. Use with sanding belts (sold separately).

For Belt | Table | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Lg. | Wd. | Lg. | Max. No-Load Speed, sfpm | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Features | Each | |

| 6" | 89" | 9 3/4" | 29" | 3,900 | One | 120V AC/240V AC | 18/9 | 3,450 | 1 1/2 | Single | Adjustable Belt Tracking, Belt-Release Lever, Dust Extraction Port, Graphite-Coated Platen, Outer Drum | 00000000 | 000000000 |

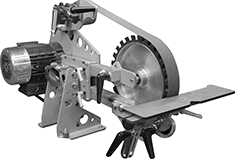

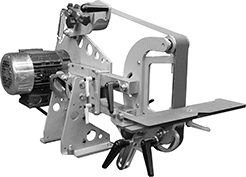

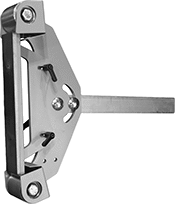

Adjustable-Configuration Stationary Belt Sanders

The most versatile sanders we offer—you can set them up in four different ways to sand flat edges, curved surfaces, inner radii, and more. Threaded handles lock and unlock each configuration and tilt the worktable, so it takes less than a minute to switch between setups and doesn’t require tools. Use either the flat platen or contact wheel to position your sanding belt both vertically and horizontally.

Use the flat platen when you need to sand flat surfaces, bevel edges, or debur something. When you use it in the horizontal position, it will give you a longer section of sanding belt to work with. To sand curved surfaces, such as tubing or pipe, you can remove the platen to loosen the belt so it wraps around your workpiece.

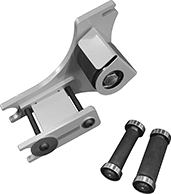

Use the contact wheel to quickly remove a lot of material. It moves at high speeds, but makes less contact with your sanding belt than the flat platen, so it won’t overheat and burn or discolor your workpiece. The small wheel attachment aligns horizontally to configure your belt into a spindle sander. The tight curve on the spindle is great for sanding corners, inner radii, and tricky shapes.

These sanders have a variable speed motor, so you can adjust them to suit everything from coarse sanding to fine finishing. These sanders and their attachments meet OSHA safety standards for machine guards.

They’re small enough that you can use them on your benchtop. Or add a stand (sold separately). You can adjust the stand height in 1" increments and store attachments on the tool arm slots.

For Belt | Table | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Lg. | Orientation | Wd. | Lg. | Max. No-Load Speed, sfpm | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Includes | Each | |

| 2" | 72" | Horizontal and Vertical | 4" | 16" | 4,700 | Variable | 120V AC/240V AC | 5.5/2.6 | 3,600 | 2 | Single | Flat Platen, Contact Wheel, Small Wheel Attachment | 0000000 | 000000000 |

| Ht. Adjustment Range | Material | Each | |

| 33" to 39" | Steel | 0000000 | 0000000 |

| Material | Each | |

| Steel | 0000000 | 0000000 |

| Includes | Each | |

| One 3/4" OD Wheel, One 1" OD Wheel | 0000000 | 0000000 |

| OD | Material | Each | |

| 2" | Aluminum | 0000000 | 000000 |

| Lg. | Wd. | Material | Each | |

| 10" | 2" | Steel | 0000000 | 000000 |

| OD | Material | Each | |

| 4" | Aluminum | 0000000 | 000000 |

| OD | Material | Each | |

| 5" | Aluminum | 0000000 | 000000 |

| Each | ||

| 0000000 | 0000000 |

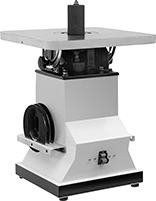

Spindle Sanders

Sand curved, contoured, and complex surfaces, such as table legs or inside holes. The spindle on these sanders oscillates while it rotates so you can use the full abrasive surface of the sanding sleeve. This motion reduces the risk of burning your workpiece and helps the sleeve last longer. The table tilts down 45° to create beveled edges. Connect these sanders to a dust collector or vacuum system to clear away debris from your workspace and prevent your sander from clogging. These sanders are small enough to fit on your workbench.

They include different sizes of spindles and table inserts for a variety of jobs. The spindles are threaded on one end, so they're easy to change out. The table inserts install around the spindle to prevent dust and debris from falling into the motor. A built-in storage rack keeps the spindles and table inserts handy.

For Sleeve | Table | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | Lg. | Wd. | Lg. | Max. No-Load Speed, rpm | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Includes | Features | Each | |

| 1/4", 1/2", 5/8", 1 1/2", 2" | 5 1/2", 6" | 14 1/2" | 14 1/2" | 1,725 | One | 120V AC | 7.5 | 1,720 | 1/2 | Single | One each Spindles for 1/4", 1/2", 5/8", 1 1/2", and 2" ID Sleeves One each 1/4" ID 100-grit Aluminum-Oxide Sanding Sleeves One each 1/2" ID 100-grit Aluminum-Oxide Sanding Sleeves One each 5/8" ID 100-grit Aluminum-Oxide Sanding Sleeves One each 1 1/2" ID 100-grit Aluminum-Oxide Sanding Sleeves One each 2" ID 100-grit Aluminum-Oxide Sanding Sleeves One each 3/4" and 2" Oblong Table Inserts One each 3/4" and 2" Round Table Inserts | Dust Extraction Port, Built-In Storage Racks | 0000000 | 0000000 |

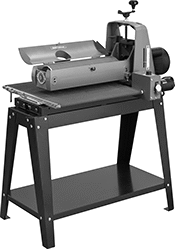

Drum Sanders

Often used in woodworking shops to efficiently level and prep boards for paneling, these sanders create a smooth, even finish on large, flat surfaces. To create this consistent finish, the wide rotating drum and conveyor keep your material in steady contact with the abrasive. The drum is made of aluminum to prevent heat from building up and wearing down the sandpaper or burning your panels. Easy to adjust, all it takes is a turn of the dial to align the drum and conveyor. These sanders have a port to connect to a dust collector or vacuum system to keep your workspace clean and reduce clogs. Sanding sheets are sold separately.

These sanders are open on one end to make room for your workpiece to hang out when you’re sanding a piece that’s wider than the drum length. Maximum workpiece width assumes you’ll flip your workpiece around to take two passes through these sanders.

Sanders with a 10" drum are sized to fit comfortably on your workbench.

Sanders with a 19" drum come with a stand. They automatically adjust the conveyor speed based on the weight of your workpiece to prevent burning or gouging the surface. This also helps you create a consistent finish if your workpiece has varying densities. They automatically tension the sanding sheet as you wrap it around the drum and help you make sure the sheet overlaps correctly. A lock holds the drum at the height you’ve set.

For Max. Workpiece | Drum | Table | No-Load Speed | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wd. | Thick. | Lg. | Dia. | Material | Wd. | Lg. | Min. | Max. | No. of Speeds | Voltage | Current, A | Motor Speed, rpm | hp | Phase | Includes | Features | Each | |

| 20" | 3" | 10" | 5" | Aluminum | 10" | 15" | 0 fpm | 10 fpm | Variable | 120V AC | 8 | 1,720 | 1 | Single | __ | Dust Extraction Port | 00000000 | 000000000 |

| 38" | 4" | 19" | 5" | Aluminum | 22 1/2" | 22 1/2" | 0 fpm | 10 fpm | Variable | 120V AC | 15 | 1,740 | 1 3/4 | Single | Steel Stand | Dust Extraction Port | 00000000 | 00000000 |

Also known as abrasive wraps, these sheets are cut to fit around the drum of a drum sander. They’re coated with aluminum oxide, the most common abrasive for general use. Tough and fracture resistant, it’s often used to smooth wood and metal.

For 10" Drum Lg. | For 19" Drum Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grit | For Use On | Abrasive Material | Abrasive Backing Material | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | ||

For Rough Finish | |||||||||

| 36 | Steel, Wood | Aluminum Oxide | Paper | __ | 000000 | 00 | 3 | 00000000 | 000000 |

| 60 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 000000 | 3 | 00000000 | 00000 |

| 80 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |

For Smooth Finish | |||||||||

| 100 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |

| 120 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |

| 150 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |

| 180 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |

| 220 | Steel, Wood | Aluminum Oxide | Paper | 6 | 00000000 | 00000 | 3 | 00000000 | 00000 |