About Air Preparation

More

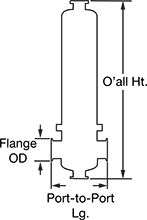

Sanitary Metal Filter Housings

Along with a cartridge, these housings are used in liquid processing lines to filter contaminants and minimize bacteria growth in food and pharmaceutical plants, as well as other sanitary environments. Made of 316 stainless steel, they won’t corrode from frequent washdowns with harsh cleaners. With a self-draining design, rounded edges, and highly polished surfaces, they leave no space for liquids to linger or bacteria to grow. These housings connect to process lines with sanitary quick-clamp fittings that allow for fast disassembly and cleaning. An EPDM rubber gasket maintains a tight seal and resists water, detergents, chemicals, and steam. The gasket is FDA compliant for direct contact with food. Housings are 3-A certified for sanitary design standards and comply with FDA pharmaceutical equipment design standards.

Cartridges (sold separately) are pleated, creating a large surface area for trapping debris. They have one open end with an EPDM rubber O-ring and locking tabs—the O-ring creates a tight seal to ensure that liquids pass through the cartridge for filtration, while the locking tabs help align with cartridges for a secure fit. Cartridges are FDA compliant for direct contact with food.

Cartridges with a polypropylene filter are often used as pre-filters in liquid processing lines, capturing larger particles to prevent clogging.

Cartridges with a PES filter remove extremely small particles, so they’re commonly used as final filters in high-purity applications. They’re also known as absolute-rated cartridges.

For Cartridge | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Ht. | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Port-to-Port Length | Overall Height | Specifications Met | Each | |

| 1" | 1.984" | 21.9" | 2.2" | O-Ring End Caps | 1 | 15 | 150 | 300 | 9 13/16" | 32 1/4" | 3-A Certified 10-04, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 0000000 | 000000000 |

Removes Particle Size Down To, microns | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | 80% Efficiency | 90% Efficiency | 98% Efficiency | 99.9% Efficiency | Max. Pressure, psi | Max. Temp., °F | Specifications Met | Each | |

Polypropylene Plastic | |||||||||

| 21.9" | 3 | 5 | 10 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 |

| 21.9" | 10 | 20 | 30 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

PES Plastic | |||||||||

| 21.9" | __ | __ | __ | 0.2 | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2240, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

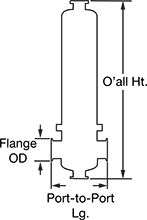

Sanitary Metal Filter Housings with Cartridge

for Food and Beverage Steam Lines

Remove contaminants, moisture, and other particles from steam that will touch food and for final filtering in pharmaceutical, biotech, and electronics applications. The cartridge in these housings filters out 98% of particles as small as 1 micron and 100% of particles as small as 2 microns. That’s why they meet 3-A’s accepted practice for creating culinary-grade steam, which is often used in steam-in-place (SIP) cycles to sanitize equipment, and for applications such as blanching. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

All are made of 316 stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them, and they withstand steam. These housings are designed to sanitary standards; they’re 3-A certified 10-04 and meet ASME BPE. They have rounded edges and highly polished interior and exterior surfaces, minimizing the spots where bacteria could grow. For the same reason, they don’t have horizontal ledges—liquid completely drains off.

They connect to your line with two quick-clamp fittings that are easy to take apart for cleaning and line reconfiguration. Each fitting is tightly sealed with an EPDM gasket, which has excellent resistance to steam.

Cartridges can be cleaned and reused, but after six cleanings you should replace them to maintain high performance.

Filter Housings with Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Removes Particle Size Down To, microns | Replacement Cartridges | |||||||||||||

| For Tube OD | Flange OD | Steam Capacity | 98% Efficiency | 100% Efficiency | Max. Pressure, psi | Max. Temp., °F | Cartridge Useful Life | Port-to-Port Length | Overall Height | Specifications Met | Each | Each | ||

Quick Clamp Tube Vent and Drain | ||||||||||||||

316 Stainless Steel Housing and Cartridge | ||||||||||||||

| 1/2" | 0.984" | 100 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 4 23/32" | 9" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 | 0000000 | 0000000 |

| 1" | 1.984" | 400 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 14 1/2" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 000000 |

| 2" | 1.984" | 800 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 19 3/4" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 00000000 |

Clean Room Compressed Air Filters for Particle Removal

Assembled, inspected, and packaged in a clean environment, these filters come sealed in antistatic double bags. Use them to remove particles and water droplets from your compressed air to extend the service life of air-powered tools and equipment. Filters have a clear bowl so you can see inside to monitor contents.

O'all | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Flow Rate | Max. Pressure, psi | Removes Particle Size Down To, microns | Includes | Ht. | Wd. | Environmental Rating | Each | |

NPT Female Inlet and Outlet | |||||||||

Polycarbonate Plastic Bowl—Clear Without Drain | |||||||||

| 1/8 | 53 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 4" | 1 5/8" | Fed. Std. Class 1, ISO Class 3 | 0000000 | 000000 |

| 1/4 | 128 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 5 3/8" | 2 1/8" | Fed. Std. Class 1, ISO Class 3 | 000000 | 00000 |

| 3/8 | 128 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 5 3/8" | 2 1/8" | Fed. Std. Class 1, ISO Class 3 | 000000 | 00000 |

| 1/2 | 206 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 6 3/4" | 2 3/4" | Fed. Std. Class 1, ISO Class 3 | 000000 | 00000 |

| 3/4 | 212 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 7" | 3" | Fed. Std. Class 1, ISO Class 3 | 000000 | 00000 |

| 1 | 427 scfm @ 100 psi | 145 | 5 | Mounting Bracket | 10" | 3 5/8" | Fed. Std. Class 1, ISO Class 3 | 0000000 | 00000 |

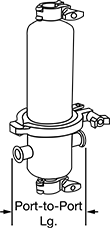

Sanitary Compressed Air Filters for Oil, Particle, and Bacteria Removal

Remove bacteria, viruses, moisture, and other particles from compressed air and gases used in food, pharmaceutical, biotech, and electronics applications. These air filters catch 99.99% of particles as small as 0.003 microns. That’s why they meet 3-A’s accepted practice for creating sterile air, which is used in applications such as tank ventilation, pharmaceutical packaging, and beer fermentation. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

Designed for sanitary areas, these air filters are 3-A certified 10-04 and meet ASME BPE. Their housing and filter element are stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them. They can also be sterilized in an autoclave or using steam in sterilize-in-place (SIP) procedures. To make sure water and cleaning liquids drain off, these air filters don’t have any horizontal ledges. The smooth, polished sides and rounded edges minimize spots where bacteria could grow.

These air filters have two quick-clamp fittings, which are easy to remove for cleaning and access to your line. Each fitting has an EPDM gasket for a tight seal and excellent resistance to steam.

To maintain high performance, replace the filter element every 150 cycles.

| For Tube OD | Flange OD | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Filter Service Indicator Included | Overall Ht. | Port-to-Port Lg. | Gasket Material | Features | Specifications Met | Each | |

Quick Clamp Tube Vent and Drain | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

316 Stainless Steel Housing—Opaque with Automatic Drain | |||||||||||||

| 1/2" | 0.984" | 36 scfm @ 100 psi | 230 | 390° | 0.003 | No | 9" | 4 23/32" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 |

| 3/4" | 0.984" | 108 scfm @ 100 psi | 230 | 390° | 0.003 | No | 11 1/8" | 4 23/32" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

| 1" | 1.984" | 216 scfm @ 100 psi | 230 | 390° | 0.003 | No | 14 1/2" | 6 3/8" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

| 2" | 2.516" | 432 scfm @ 100 psi | 230 | 390° | 0.003 | No | 19 3/4" | 6 3/8" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

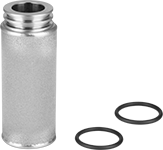

| For Tube OD | Material | Max. Temp., °F | Removes Particle Size Down To, microns | End Cap Material | O-Ring Material | Each | |

| 1/2" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 0000000 |

| 3/4" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 000000 |

| 1" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 000000 |

| 2" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 00000000 |