About Pressure Transmitters

More

About Pressure Switches

More

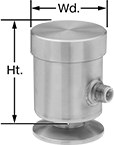

Sanitary Pressure Transmitters

- For Use With: Air, Argon, Diesel Fuel, Gasoline, Hydraulic Fluid, Nitrogen, Water

- Accuracy: ±0.5%

- Housing Material: 304 Stainless Steel

- Connection Material: 316 Stainless Steel

- Temperature Range: 30° to 300° F

For use in sanitary applications such as food processing, these transmitters are 3-A certified. They are rated IP66, IP69K, and NEMA 4X to resist washdowns and corrosion. Also known as transducers, they convert pressure to an electrical signal that can be interpreted by receiving devices, such as remote displays, programmable logic controllers, and motor speed controls to monitor pressure or control equipment. As pressure increases, the output signal from the transmitter will increase. For your receiving device to interpret the signal from the transmitter, you will need to calibrate it for the transmitter's pressure range and output signal. Transmitters are accurate only within the pressure range.

These transmitters connect using two wires to send a 4-20mA current output. The same wire is used to send a signal to the receiver and to power the transmitter. Current doesn’t lose signal over long distances and isn’t affected by electrical interference from other devices. Transmitters are compatible with micro M12 sockets.

| Pressure Range, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Input Voltage | Ht. | Wd. | Environmental Rating | Specifications Met | Each | |

For 1 1/2" Flange OD | |||||||||

|---|---|---|---|---|---|---|---|---|---|

4-20mA Current Output—5-Pole Micro M12 Plug Connection | |||||||||

| 0-15 | 15 | 30 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 0000000 |

| 0-50 | 50 | 100 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-100 | 100 | 200 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-200 | 200 | 400 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-500 | 500 | 1,000 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

For 2" Flange OD | |||||||||

4-20mA Current Output—5-Pole Micro M12 Plug Connection | |||||||||

| 0-15 | 15 | 30 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-50 | 50 | 100 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-100 | 100 | 200 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-200 | 200 | 400 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

| 0-500 | 500 | 1,000 | 10-40V DC | 2 5/16" | 2 7/16" | IP66, IP69K, NEMA 4X | 3-A Certified 74-06, CE Marked | 00000000 | 000000 |

Sanitary Pressure Switches

3-A certified, these food-safe switches trigger automated controls and alarms when food-processing, pharmaceutical, and biotech lines reach a set pressure. These switches have many features that make them safe for sanitary environments because they reduce the space where bacteria could grow. A sleeve shields internal parts from water and other contaminants. Polished surfaces and smoothly welded seams make cleaning easier. Made of 316 stainless steel, they stand up to harsh cleaners and sanitizers without rusting. Rated IP67 and NEMA 6, they’re dust tight and withstand washdowns and temporary submersion.

Connect them to your line with the same quick-clamp fittings (also known as tri-clamp fittings) that are common on sanitary lines since they’re easy to take apart for cleaning. The quick-clamp end has a diaphragm that protects the switches from corrosive material and covers threads to keep them clean. The diaphragm is filled with 99.5% pure USP food-grade glycerin, which keeps the switch clean if the diaphragm fails. It’s also laser etched with the serial number to reduce crevices.

Twist the adjustable setpoint ring to make quick changes. These switches are single pole, double throw (SPDT) and can be installed to turn one circuit from off to on (normally open) or from on to off (normally closed).

All have a certificate with traceable lot number and material test report.

| Setpoint, psi | Approximate Difference Between Setpoint and Reset Point, psi | Max. Continuous Pressure, psi | Max. Short-Term Pressure, psi | Accuracy | Max. Switching Current | Process Temp. Range, °F | Connection Material | Width | For Use With | Specifications Met | Each | |

Wire Leads | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 1/2" Tube OD Quick-Clamp Connection | ||||||||||||

| 6 to 30 | 3 | 30 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 0000000 |

| 8 to 60 | 5 | 60 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

| 10 to 100 | 4 | 100 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

| 20 to 200 | 16 | 200 | 1,000 | ±5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

2" Tube OD Quick-Clamp Connection | ||||||||||||

| 6 to 30 | 3 | 30 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2 1/2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

| 8 to 60 | 6 | 60 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2 1/2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

| 10 to 100 | 4 | 100 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2 1/2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

| 20 to 200 | 16 | 200 | 1,000 | ±5% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | 2 1/2" | Beverage, Food | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

Sanitary Pressure and Vacuum Switches

When these 3-A certified switches reach a set pressure or vacuum, they trigger controls and alarms in food-processing, pharmaceutical, and biotech lines. They have a sleeve to shield internal parts from water and contaminants. Their surfaces are polished and their seams are continuously welded, so cleaning is easy and there’s little room for bacteria to grow. Made of 316 stainless steel, these switches stand up to harsh cleaners and sanitizers without rusting. Rated IP67 and NEMA 6, they’re dust tight and protected from washdowns and temporary submersion.

They connect using the same quick-clamp fittings (also known as tri-clamp fittings) that are common in sanitary lines, because they’re easy to take apart for cleaning. This end has a diaphragm that protects from corrosion and covers threads to keep them clean. The diaphragm is filled with 99.5% pure USP food-grade glycerin, reducing the risk of contamination if the diaphragm fails. The serial number is laser etched on the diaphragm to reduce crevices.

Twist the adjustable setpoint ring to make quick changes. These switches are single pole, double throw (SPDT) and can be installed to turn one circuit from off to on (normally open) or from on to off (normally closed).

All have a certificate with a traceable lot number and material test report.

Setpoint | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure, psi | Vacuum, in. of Hg | Approximate Difference Between Setpoint and Reset Point, psi | Maximum Continuous Pressure, psi | Maximum Short-Term Pressure, psi | Accuracy | Maximum Switching Current | Process Temp. Range, °F | Connection Material | For Use With | Specifications Met | Each | |

Wire Leads | ||||||||||||

1 1/2" Tube OD Quick-Clamp Connection | ||||||||||||

| 0-15 | 30-0 | 3 | 15 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | 3-A Certified 74-07, UL Listed | 00000000 | 0000000 |

2" Tube OD Quick-Clamp Connection | ||||||||||||

| 0-15 | 30-0 | 3 | 15 | 1,000 | ±2% | 5 A @ 125 V AC 5 A @ 250 V AC 3 A @ 28 V DC | -40° to 212° | 316 Stainless Steel | Argon, Beverage, Diesel Fuel, Food, Gasoline, Hydraulic Fluid, Inert Gas, Natural Gas, Nitrogen, Oil, Oxygen, Water | 3-A Certified 74-07, UL Listed | 00000000 | 000000 |

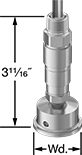

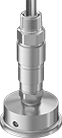

Sanitary Electronic Insertion Flow Switches

Easy to clean and install, these flow switches are 3-A certified to meet sanitary design standards and insert into your line with a quick-clamp mounting adapter (sold separately). They have a smooth probe, and unlike flow switches that measure with a paddle or turbine, these don’t have moving parts for contaminants to get stuck in. Rated IP67 and IP69K, they withstand temporary submersion and high-temperature, high-pressure washdowns. The mounting adapter attaches to a quick-clamp tube tee or outlet (often called tri-clamp fittings) in your large-diameter tubing system using a gasket and clamp (not included), so you don't need to disassemble your line for inline installation. This mounting adapter is also easy to remove and clean.

They send digital signals to your programmable logic controller (PLC) to activate automated controls or alarms when they reach a set flow rate. To calculate the flow rate, they generate a small amount of heat, then measure the cooling effect your liquid or gas has on it. This makes them ideal in applications with fluctuating temperatures. Use the buttons on the display to adjust the set point and other settings. They’re accurate in any mounting orientation.

Set Point Range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Liquids, gpm | For Gases, scfm | Max. Pressure | Temp. Range, °F | Max. Switching Current @ Voltage | Body Ht. | Environmental Rating | Specifications Met | Each | |

13/16" Probe Lg. | ||||||||||

316 Stainless Steel Body | ||||||||||

One Digital PNP Signal Output | ||||||||||

| 1 1/2" 2" | 0.55 to 54.21 0.97 to 96.37 | 4.84 to 72.47 8.59 to 128.84 | 430 psi @ 70° F | -10° to 200° | 250 mA @ 19 V DC, 250 mA @ 36 V DC | 3 5/16" | IP67, IP69K | 3-A Certified 74-07, C-UL Listed, CE Marked, FDA Compliant 21 CFR 177.2415, UL Listed | 0000000 | 0000000 |

1 13/16" Probe Lg. | ||||||||||

316 Stainless Steel Body | ||||||||||

One Digital PNP Signal Output | ||||||||||

| 1 1/2" 2" | 0.55 to 54.21 0.97 to 96.37 | 4.84 to 72.47 8.59 to 128.84 | 430 psi @ 70° F | -10° to 200° | 250 mA @ 19 V DC, 250 mA @ 36 V DC | 3 5/16" | IP67, IP69K | 3-A Certified 74-07, C-UL Listed, CE Marked, FDA Compliant 21 CFR 177.2415, UL Listed | 0000000 | 000000 |