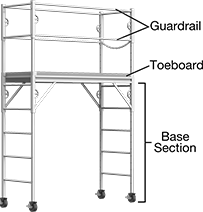

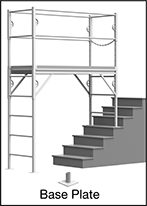

Uneven Surface Scaffolds

Even if your surface isn't level, your scaffold can be—the end frames on these scaffolds adjust independently so you can set each side at a different height. You can change the plank height in 4" increments; use the spring-loaded pins to lock it in place.

Outriggers are required by OSHA when add-on height sections are used. They extend the base by 20" per side.

Note: Scaffolds meet OSHA dimensional standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe installation and operating practices. Scaffolds also meet CAL-OSHA standards, which is required for use in California.

Wheel | Stem | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Dia. | Lg. | Wheel/Tread Material | Caster Type | Each | |

| 5" | 1 1/8" | 6 1/4" | 250 | 5/8" | 2" | Rubber | Swivel with Brake | 0000000 | 000000 |

| Lg. | Wd. | Specifications Met | Each | |

| 4 5/8" | 4 5/8" | ANSI A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 0000000 | 000000 |

| Wheel Configuration | Brake Type | No. of Wheel Brakes | Includes | Specifications Met | Each | |

| Four Swivel Casters | Wheel Brake | 4 | Four Outriggers | ANSI A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451 | 0000000 | 0000000 |

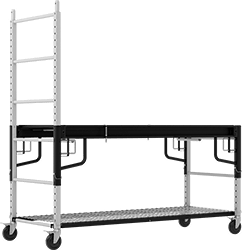

Motorized Adjustable Scaffolds

Move these scaffolds between work areas without climbing down from the platform. They have a pair of motorized wheels that you control with a joystick. When you stop moving, the motor locks them to keep these scaffolds in place. The steel frame is durable enough to withstand heavy use, and it’s powder-coated to prevent rust. Holes every 2" let you adjust the platform to the height you need. To prevent slips, the walking surface is coated in grit. These scaffolds also have an access door, so you can climb down through the platform when you’re in tight spots.

Use a standard 20V battery (not included) to power the motor. It comes with adapters for most power tool battery packs.

Note: These scaffolds meet OSHA and Cal/OSHA dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe operating practices. They’re designed to be driven on level surfaces, and don’t exceed the OSHA-required maximum speed of 1 foot per second. The enclosed guardrails meet fall-protection requirements.

Scaffolds | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Plank | Overall | Replacement Casters | ||||||||||||||||||||

| Platform Ht. | Guardrail Ht. | Toeboard Ht. | Lg. | Wd. | Ht. | Lg. | Wd. | Cap., lbs. | Color | Max. Speed, mph | Range, ft. | Batteries Included | For Battery Voltage | Wheel Configuration | No. of Wheel Brakes | Assembled or Unassembled | Includes | Specifications Met | Each | Each | ||

Powder-Coated Steel | ||||||||||||||||||||||

| 29"-71" | 41" | 4" | 5'7" | 29" | 7'8"-9'10" | 76" | 31" | 500 | Red | 0.68 | 4,500 | No | 18V DC, 20V DC | Four Swivel Casters | 4 | Unassembled | Cord Grips, Grit-Coated Plywood Plank, Guardrail, Guardrail Posts, Joystick, Motorized Wheel Assembly, Two End Frames, Two Horizontal Braces | Cal/OSHA Compliant Title 8 Section 1637 Cal/OSHA Compliant Title 8 Section 1646 OSHA Compliant 29 CFR 1926.451 | 0000000 | 000000000 | 0000000 | 000000 |

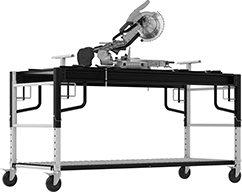

Multifunction Workbench Adjustable Scaffolds

Save space with a rolling scaffold that doubles as a workbench. These scaffolds can be used as a miter saw stand, a storage rack, a utility cart—or as scaffolding. Made of powder-coated steel, they're both rust resistant and durable for industrial use. Height adjusts in 2" increments.

Note: Scaffolds meet OSHA and Cal/OSHA dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Scaffolds | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Plank | Overall | Replacement Casters | ||||||||||||||

| Platform Ht. | Lg. | Wd. | Ht. | Lg., ft. | Wd. | Cap., lbs. | Color | Wheel Configuration | No. of Wheel Brakes | Assembled or Unassembled | Includes | Specifications Met | Each | Each | ||

Powder-Coated Steel | ||||||||||||||||

| 25 1/8"-73" | 5'7" | 29" | 3'1"-6'2" | 6 | 30 1/2" | 1,100 | Yellow | Four Swivel Casters | 4 | Unassembled | Reversible Plywood Plank/Miter Saw Stand, Storage Rack, Two End Frames with Adjustable Legs, Two Horizontal Braces | Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646, Cal/OSHA Compliant Title 8 Section 3622, Cal/OSHA Compliant Title 8 Section 3627, OSHA Compliant 29 CFR 1926.451, ANSI/ASSP A10.8 | 00000000 | 0000000 | 00000000 | 000000 |

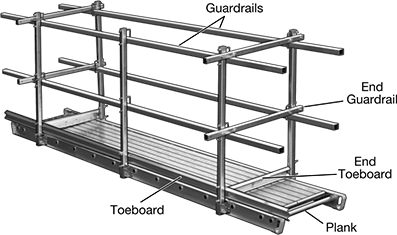

Planks, Guardrails, and Toeboards

Create catwalks, bridges, gangways, and mezzanines by combining these planks, guardrails, and toeboards. They also work well between trestles, ladder jacks, and ladder scaffolding supports. Rungs on the underside are for use as hand grips.

Planks have a slip-resistant surface for sure footing. The vinyl end caps protect against sharp edges and act as hand grips.

Guardrails mount to either side of the plank with the upper rails 38" to 42" above the plank surface.

Toeboards mount to either side of the plank. They clamp to guardrail posts.

Note: Planks, guardrails, and toeboards meet OSHA dimensional standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe installation and operating practices. Planks, guardrails, and toeboards also meet CAL-OSHA standards, which is required for use in California.

| Lg., ft. | Ht. | Wt., lbs. | Material | Plank Tread | Mounting Hardware Included | Assembled or Unassembled | Specifications Met | Each | |

500-lb. Capacity | |||||||||

|---|---|---|---|---|---|---|---|---|---|

14" Wd. | |||||||||

| 8 | 4" | 27 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 0000000 |

| 12 | 4" | 40 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 16 | 5" | 58 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 6" | 85 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

20" Wd. | |||||||||

| 8 | 4" | 33 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 12 | 4" | 48 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 16 | 5" | 70 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 6" | 102 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 24 | 6" | 121 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

24" Wd. | |||||||||

| 8 | 4" | 38 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 12 | 4" | 56 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 16 | 5" | 81 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 6" | 115 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

| 24 | 6" | 138 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

28" Wd. | |||||||||

| 8 | 4" | 41 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 12 | 4" | 60 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 6" | 124 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

| 24 | 6" | 147 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

750-lb. Capacity | |||||||||

28" Wd. | |||||||||

| 12 | 4" | 71 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 16 | 5" | 103 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 5" | 128 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

| 24 | 6" | 161 | Aluminum | Smooth | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000000 |

| For Plank Lg., ft. | Material | Mounting Hardware Included | Assembled or Unassembled | Includes | Specifications Met | Each | |

| 8 | Aluminum | Yes | Unassembled | Midrail, Vertical Posts | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 0000000 |

| 12 | Aluminum | Yes | Unassembled | Midrail, Vertical Posts | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 16 | Aluminum | Yes | Unassembled | Midrail, Vertical Posts | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | Aluminum | Yes | Unassembled | Midrail, Vertical Posts | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 24 | Aluminum | Yes | Unassembled | Midrail, Vertical Posts | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| For Plank Lg., ft. | Toeboard Ht. | Material | Mounting Hardware Included | Assembled or Unassembled | Specifications Met | Each | |

| 8 | 3 1/2" | Aluminum | No | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 12 | 3 1/2" | Aluminum | No | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 00000 |

| 16 | 3 1/2" | Aluminum | No | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 20 | 3 1/2" | Aluminum | No | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| 24 | 3 1/2" | Aluminum | No | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 000000 |

| For Plank Wd. | Toeboard Ht. | Material | Mounting Hardware Included | Assembled or Unassembled | Specifications Met | Each | |

| 20", 24", 28" | 3 1/2" | Aluminum | Yes | Unassembled | ANSI/ASSP A10.8, Cal/OSHA Compliant Title 8 Section 1637, OSHA Compliant 29 CFR 1926.451, UL 1322 | 0000000 | 0000000 |

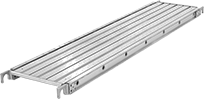

Aluminum Scaffold Planks

Aluminum is a good choice for damp areas and outdoor use. Hooks with a 2" opening at each end secure planks to end frames. Rungs on the underside are for use as hand grips. Planks have a perforated surface for slip resistance and to reduce debris buildup. End hooks are offset to allow for continuous planking of large scaffolds.

Note: Length is measured from center-to-center of end hooks.

Note: Planks meet OSHA and Cal/OSHA dimensional and construction standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe set-up and operating practices.

Rail | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Wd. | Ht. | Cap., lbs. | Plank Tread | Ht. | Material | Wt., lbs. | Assembled or Unassembled | Features | Specifications Met | Each | |

| 7 | 19 1/16" | 3" | 250 | Perforated | 3" | Aluminum | 25 | Unassembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, UL 1322 | 0000000 | 0000000 |

| 8 | 19 1/16" | 4" | 250 | Perforated | 4" | Aluminum | 34 | Unassembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, UL 1322 | 0000000 | 000000 |

| 10 | 19 1/16" | 4" | 250 | Perforated | 4" | Aluminum | 43 | Unassembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, UL 1322 | 0000000 | 000000 |

Plywood Scaffold Planks

The most commonly used and cost-effective planking for scaffolding walkways. Install three of these planks side-by-side to create a full platform atop standard 5 ft. wide scaffold frames. Hooks with a 2" opening at each end secure these planks to end frames. Their plywood walking surface can be replaced with standard 5/8" thick plywood when worn.

Note: Length is measured from center-to-center of end hooks.

Note: Planks meet OSHA dimensional standards. Users are responsible for checking local, state, and federal codes, including OSHA, for safe installation and operating practices.

Rail | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. | Wd. | Ht. | Cap., lbs. | Plank Tread | Ht. | Material | Wt., lbs. | Assembled or Unassembled | Features | Specifications Met | Each | |

| 7 | 19" | 4" | 1,000 | Smooth | 4" | Aluminum | 34 | Assembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646 | 0000000 | 0000000 |

| 8 | 19" | 4" | 750 | Smooth | 4" | Aluminum | 42 | Assembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646 | 0000000 | 000000 |

| 10 | 19" | 4" | 1,000 | Smooth | 4" | Aluminum | 46 | Assembled | 2" End Hooks | ANSI/ASSP A10.8, OSHA Compliant 29 CFR 1926.451, Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646 | 0000000 | 000000 |

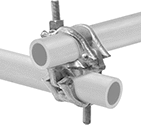

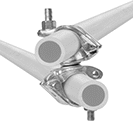

Scaffold Clamps

Build tube-and-clamp scaffolding and attach supports, such as railings, to frame-style structures. Also known as knuckles. These clamps fit the most common scaffold tube sizes. Made of galvanized steel, they are rust resistant and hold up in outdoor applications.

Rigid clamps create a secure 90° connection between two tubes.

Swivel clamps pivot to connect tubes at any angle.

Note: Clamps meet OSHA and Cal/OSHA dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

For OD | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Movement | Inch | Metric, mm | No. of Through Holes | Material | Drive Style | Hex Size, mm | Specifications Met | Each | |

| Rigid | 1 5/8"-1 7/8" | 42-48 | 2 | Galvanized Steel | External Hex | 22 | Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646, OSHA Compliant 29 CFR 1926.451 | 00000000 | 000000 |

| Swivel | 1 5/8"-1 7/8" | 42-48 | 2 | Galvanized Steel | External Hex | 22 | Cal/OSHA Compliant Title 8 Section 1637, Cal/OSHA Compliant Title 8 Section 1646, OSHA Compliant 29 CFR 1926.451 | 00000000 | 00000 |