About Torque Tools

More

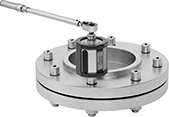

Square Drive Torque Tool Testers

Check the accuracy of torque wrenches and screwdrivers—place your tool onto the tester with the included square drive connector and turn. The main pointer shows torque as it's measured; Testers with memory pointer show the maximum torque reached. Use these testers with hand tools only.

Note: For the most accurate performance, the maximum torque you apply should fall near the middle of the tester’s torque range.

Accuracy | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | Lg. | Wd. | Ht. | Material | Mounting Fasteners Included | No. of | Dia. | Each | |

With Calibration Certificate Traceable to NIST | ||||||||||||||

ft.-lbs. | ||||||||||||||

| 1/2" | 10 to 50 ft.-lbs. | 1 ft.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 13" | 4" | 2 1/2" | Steel | No | 4 | 1/4" | 0000000 | 000000000 |

| 1/2" | 20 to 100 ft.-lbs. | 2 ft.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 13" | 4" | 2 1/2" | Steel | No | 4 | 1/4" | 0000000 | 00000000 |

| 1/2" | 30 to 150 ft.-lbs. | 2.5 ft.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 13" | 4" | 2 1/2" | Steel | No | 4 | 1/4" | 0000000 | 00000000 |

| 1/2" | 40 to 200 ft.-lbs. | 5 ft.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 13" | 4" | 2 1/2" | Steel | No | 4 | 1/4" | 0000000 | 00000000 |

| 3/4" | 120 to 600 ft.-lbs. | 10 ft.-lbs. | Clockwise and Counterclockwise | ±2% | ±2% | 14 1/2" | 4 3/4" | 3 3/4" | Steel | No | 6 | 1/4" | 0000000 | 000000 |

High-Accuracy Torque Tool Testers

Accurate to within ±1%, these torque testers are often used to check the accuracy of torque wrenches and screwdrivers on assembly lines. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. To test, place your torque wrench or screwdriver onto the tester with the included square drive connection and turn. These testers display torque as it's measured and the maximum torque reached. For accuracy when testing click-style wrenches, they also show the first torque peak reached. They’re not for use with impact or pulse tools.

Note: For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range.

Bench-top testers can be mounted to your work surface. Those with a gooseneck display can be bent until you can clearly see the test results. Mount these testers to your workbench with a mounting bracket (sold separately). Or, carry them where they’re needed using the included case.

Accuracy | Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | For Tool Type | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Batteries Included | Includes | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | ||||||||||||||||

in.-lbs., ft.-lbs., Nm | ||||||||||||||||

| 1/4" | 5 to 50 in.-lbs. 0.4 to 4.17 ft.-lbs. 0.56 to 5.65 Nm | 0.01 in.-lbs. 0.01 ft.-lbs. 0.01 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 000000000 |

| 3/8" | 25 to 250 in.-lbs. 2 to 21 ft.-lbs. 2.8 to 28.2 Nm | 0.1 in.-lbs. 0.01 ft.-lbs. 0.01 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 00000000 |

| 3/8" | 60 to 600 in.-lbs. 5 to 50 ft.-lbs. 6.78 to 67.8 Nm | 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 00000000 |

| 1/2" | 300 to 3,000 in.-lbs. 25 to 250 ft.-lbs. 33.8 to 338 Nm | 1 in.-lbs. 0.1 ft.-lbs. 0.1 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 00000000 |

| 3/4" | 720 to 7,200 in.-lbs. 60 to 600 ft.-lbs. 81.3 to 813 Nm | 1 in.-lbs. 0.1 ft.-lbs. 0.1 Nm | Clockwise and Counterclockwise | ±1% | ±1% | Hand Tools Only | 4 1/2" | 6" | 6" | No | 8 | 3/8" | Yes | Female Drive Adapter | 0000000 | 00000000 |

Accuracy | Mounting Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Torque-Measuring Direction | Clockwise | Counterclockwise | For Tool Type | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Includes | Each | |

With Calibration Certificate with Test Data Traceable to NIST Certificate of Calibration | |||||||||||||||

ft.-lbs., Nm | |||||||||||||||

| 1/2" | 25 to 250 ft.-lbs. 34 to 339 Nm | 1 ft.-lbs. 1 Nm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | Hand Tools Only | 2 1/2" | 4 1/2" | 14 1/2" | No | 6 | 5/16" | Carrying Case, Female Drive Adapter | 0000000 | 000000000 |

| 3/4" | 60 to 600 ft.-lbs. 81 to 813 Nm | 1 ft.-lbs. 1 Nm | Clockwise and Counterclockwise | ±0.5% | ±0.5% | Hand Tools Only | 2 1/2" | 4 1/2" | 14 1/2" | No | 6 | 5/16" | Carrying Case, Female Drive Adapter | 0000000 | 00000000 |

Mounting Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | Wd. | Ht. | Dp. | Mounting Fasteners Included | No. Of | Dia. | Each | |

| Steel | 4 1/2" | 2 1/2" | 8 3/4" | No | 6 | 5/16" | 0000000 | 0000000 |

Rotary Torque Testers

Monitor torque as you apply it—these testers mount between your torque tool and your fastener. Engage the fastener to track both torque and the angle of rotation for each crank of your tool (snug torque) before you've reached the final torque. This gives you a better idea if fasteners are consistently tightened than measuring torque alone. These testers are often used with nutrunners and click-style torque wrenches in the automotive and aerospace industries. Store up to 999 maximum torque (peak) and rotation values, including the date and time of each test, or transfer to your computer to view in an Excel file. CE marked, they meet European safety standards.

For the most accurate readings, the maximum torque you're applying should fall near the middle of the tester's torque range. They are not for use with impact tools.

Testers with a USB connection transfer data directly to your computer with the included cord. These testers last up to 10 hours on a single charge.

Testers with a Bluetooth connection wirelessly transmit data to a computer as you measure. You can also remotely set snug torque, or when these testers starting measuring the torque applied with each rotation. They last up to 8 hours on a single charge with Bluetooth on and 10 hours with it off.

Accuracy | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Drive Size | Torque Range | Graduations | Clockwise | Counterclockwise | Lg. | OD | Features | Battery Type | Battery Charger Included | Includes | Each | |

USB-B Data Connection | ||||||||||||

| 1/4" | 280 to 1,400 in.-oz. 17.6 to 88 in.-lbs. 1.5 to 7.3 ft.-lbs. 20 to 100 kgf-cm 0.2 to 1 kgf-m 200 to 1,000 cNm 2 to 10 Nm | 1 in.-oz. 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 kgf-cm 0.001 kgf-m 1 cNm 0.01 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 000000000 |

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 1/2" | 176 to 880 in.-lbs. 15 to 73 ft.-lbs. 200 to 1,000 kgf-cm 2 to 10 kgf-m 20 to 100 Nm | 1 in.-lbs. 0.1 ft.-lbs. 1 kgf-cm 0.01 kgf-m 0.1 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

| 1/2" | 350 to 1,750 in.-lbs. 30 to 145 ft.-lbs. 400 to 2,000 kgf-cm 4 to 20 kgf-m 40 to 200 Nm | 2 in.-lbs. 0.2 ft.-lbs. 2 kgf-cm 0.02 kgf-m 0.2 Nm | ±1% | ±1% | 2 15/16" | 1 13/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | 6 1/2-ft. Long USB Cord, AC Adapter | 0000000 | 00000000 |

Bluetooth Data Connection | ||||||||||||

| 1/4" | 280 to 1,400 in.-oz. 17.6 to 88 in.-lbs. 1.5 to 7.3 ft.-lbs. 20 to 100 kgf-cm 0.2 to 1 kgf-m 200 to 1,000 cNm 2 to 10 Nm | 1 in.-oz. 0.1 in.-lbs. 0.01 ft.-lbs. 0.1 kgf-cm 0.001 kgf-m 1 cNm 0.01 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 3/8" | 560 to 2,800 in.-oz. 35 to 175 in.-lbs. 3 to 14.5 ft.-lbs. 40 to 200 kgf-cm 0.4 to 2 kgf-m 400 to 2,000 cNm 4 to 20 Nm | 2 in.-oz. 0.2 in.-lbs. 0.02 ft.-lbs. 0.2 kgf-cm 0.002 kgf-m 2 cNm 0.02 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 3/8" | 1,400 to 7,000 in.-oz. 88 to 440 in.-lbs. 7.5 to 36.5 ft.-lbs. 100 to 500 kgf-cm 1 to 5 kgf-m 1,000 to 5,000 cNm 10 to 50 Nm | 5 in.-oz. 0.5 in.-lbs. 0.05 ft.-lbs. 0.5 kgf-cm 0.005 kgf-m 5 cNm 0.05 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 1/2" | 176 to 880 in.-lbs. 15 to 73 ft.-lbs. 200 to 1,000 kgf-cm 2 to 10 kgf-m 20 to 100 Nm | 1 in.-lbs. 0.1 ft.-lbs. 1 kgf-cm 0.01 kgf-m 0.1 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

| 1/2" | 350 to 1,750 in.-lbs. 30 to 145 ft.-lbs. 400 to 2,000 kgf-cm 4 to 20 kgf-m 40 to 200 Nm | 2 in.-lbs. 0.2 ft.-lbs. 2 kgf-cm 0.02 kgf-m 0.2 Nm | ±1% | ±1% | 2 15/16" | 1 15/16" | Plug Cover, Torque Measurement Memory | Rechargeable | Yes | AC Adapter | 0000000 | 00000000 |

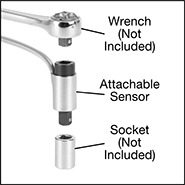

Data-Recording Torque Gauges

Use these gauges with changeable sensors and square-drive sockets (sold separately) to display, collect, and download torque readings. They display torque as it's measured and the maximum torque reached. Gauges can also be used to convert any hand-turned square drive tool into a precise torque-measuring tool. For the most accurate performance, the maximum torque you're applying should fall near the middle of the gauge's torque range.

Wrench-attachable sensors fit between your wrench and socket. Use with hand tools only.

Hand-turned sensors don't require a tool; place into your socket and turn them with your hand.

| Features | Lg. | Wd. | Ht. | Data Log Cap. | Batteries Included | Includes | Container Type | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm.-kg | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Torque Measurement Memory, Programmable Torque Settings, Maximum Torque Display, Keypad, Headphone Jack, Audible Alarm | 6" | 3" | 2 1/2" | 3,500 | Yes | 3-ft Long USB Cable | Plastic Case | 0000000 | 000000000 |

Accuracy | |||||||

|---|---|---|---|---|---|---|---|

| Square Drive Size (Gender) | Torque Range | Torque-Measuring Direction | Clockwise | Counterclockwise | Cord Lg., ft. | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm-kg | |||||||

| 1/4" (Female) × 1/4" (Male) | 80 to 800 in.-oz. 5 to 50 in.-lbs. 0.417 to 4.17 ft.-lbs. 0.565 to 5.65 Nm 56.5 to 565 cNm 0.058 to 0.576 m-kg 5.76 to 57.6 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 0000000 |

| 1/4" (Female) × 1/4" (Male) | 320 to 3,200 in.-oz. 20 to 200 in.-lbs. 1.67 to 16.7 ft.-lbs. 2.26 to 22.6 Nm 226 to 2,260 cNm 0.23 to 2.3 m-kg 23 to 230 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 3/8" (Female) × 3/8" (Male) | 120 to 1,200 in.-lbs. 10 to 100 ft.-lbs. 13.6 to 136 Nm 1,356 to 13,560 cNm 1.38 to 13.8 m-kg 138 to 1,383 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 1/2" (Female) × 1/2" (Male) | 300 to 3,000 in.-lbs. 25 to 250 ft.-lbs. 33.9 to 339 Nm 3,390 to 33,900 cNm 3.46 to 34.6 m-kg 346 to 3,456 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 4 | 0000000 | 000000 |

| 3/4" (Female) × 3/4" (Male) | 720 to 7,200 in.-lbs. 60 to 600 ft.-lbs. 81.3 to 813 Nm 8,135 to 81,350 cNm 8.3 to 83 m-kg 830 to 8,295 cm-kg | Clockwise and Counterclockwise | ±1% | ±1% | 8 | 0000000 | 000000 |

Accuracy | |||||||

|---|---|---|---|---|---|---|---|

| Square Drive Size (Gender) | Torque Range | Torque-Measuring Direction | Clockwise | Counterclockwise | Cord Lg., ft. | Each | |

in.-oz., in.-lbs., ft.-lbs., Nm, cNm, m-kg, cm-kg | |||||||

| 1/4" (Male) | 2 to 20 in.-oz. 0.125 to 1.25 in.-lbs. 0.01 to 0.104 ft.-lbs. 0.014 to 0.141 Nm 1.41 to 14.1 cNm 0.001 to 0.014 m-kg 0.144 to 1.44 cm-kg | Clockwise and Counterclockwise | ±2% | ±2% | 4 | 0000000 | 0000000 |

| 1/4" (Male) | 16 to 160 in.-oz. 1 to 10 in.-lbs. 0.083 to 0.833 ft.-lbs. 0.113 to 1.13 Nm 11.3 to 113 cNm 0.012 to 0.115 m-kg 1.15 to 11.5 cm-kg | Clockwise and Counterclockwise | ±2% | ±2% | 4 | 0000000 | 000000 |