Filter by

Nut Type

Barrel Height

Barrel Diameter

Thread Fit

DFARS Specialty Metals

Export Control Classification Number (ECCN)

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

Military Specification

Screw-Mount Nuts

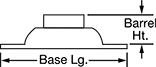

Base | Barrel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Dia. | Thk. | Dia. | Ht. | No. of Mounting Holes | Mounting Hole Dia. | No. of Projections | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6-32 | 9/16" | 1/32" | 11/64" | 1/4" | 3 | 5/64" | — | 50 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 8-32 | 23/32" | 1/32" | 7/32" | 1/4" | 3 | 7/64" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 10-24 | 3/4" | 1/32" | 1/4" | 9/32" | 3 | 7/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 10-32 | 3/4" | 3/64" | 1/4" | 9/32" | 3 | 7/64" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4"-20 | 3/4" | 3/64" | 5/16" | 1/4" | 3 | 7/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4"-20 | 3/4" | 3/64" | 5/16" | 5/16" | 3 | 7/64" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4"-20 | 3/4" | 3/64" | 5/16" | 7/16" | 3 | 7/64" | — | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4"-20 | 3/4" | 3/64" | 5/16" | 9/16" | 3 | 7/64" | — | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/4"-20 | 3/4" | 3/64" | 5/16" | 7/8" | 3 | 7/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/16"-18 | 7/8" | 1/16" | 3/8" | 3/8" | 3 | 7/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/16"-18 | 7/8" | 1/16" | 3/8" | 5/8" | 3 | 7/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/16"-18 | 7/8" | 1/16" | 3/8" | 7/8" | 3 | 7/64" | — | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-16 | 1" | 1/16" | 7/16" | 7/16" | 3 | 9/64" | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-16 | 1" | 1/16" | 7/16" | 5/8" | 3 | 9/64" | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-16 | 1 1/4" | 5/64" | 15/32" | 3/4" | 3 | 9/64" | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/2"-13 | 1 1/4" | 3/32" | 19/32" | 3/8" | 3 | 5/32" | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8"-11 | 1 7/16" | 3/32" | 23/32" | 3/8" | 3 | 5/32" | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M10 × 1.5 mm | 25.4 mm | 1.6 mm | 11.5 mm | 11.1 mm | 3 | 3.7 mm | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4"-20 | 3/4" | 3/64" | 5/16" | 5/16" | 3 | 7/64" | 3 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4"-20 | 3/4" | 3/64" | 5/16" | 7/16" | 3 | 7/64" | 3 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/4"-20 | 3/4" | 3/64" | 5/16" | 9/16" | 3 | 7/64" | 3 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/16"-18 | 7/8" | 1/16" | 3/8" | 3/8" | 3 | 7/64" | 3 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/16"-18 | 7/8" | 1/16" | 3/8" | 5/8" | 3 | 7/64" | 3 | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/2"-13 | 1 1/4" | 3/32" | 19/32" | 3/8" | 3 | 5/32" | 3 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8"-11 | 1 7/16" | 3/32" | 23/32" | 3/8" | 3 | 5/32" | 3 | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw-Mount Nuts for Wood

Mil. Spec. Rivet-Mount Nuts

|  | ||

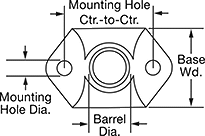

Base | Barrel | Mounting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Wd. | Thk. | Dia. | Ht. | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Mil. Spec. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel—Unlubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 1/8" | 1/16" | 2 | 0.098" | 13/32" | MS21075-04N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21075-06N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21075-08N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075-3N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075-4N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cadmium-Plated Steel—Lubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 1/8" | 1/16" | 2 | 0.098" | 13/32" | MS21075L04N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21075L06N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21075L08N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21075L3N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21075L4N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel—Unlubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21059-06 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21059-08 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059-3 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059-4 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cadmium-Plated Carbon Steel—Lubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 61/64" | 13/32" | 1/32" | 0.141" | 9/64" | 2 | 0.098" | 11/16" | MS21059L04 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21059L06 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21059L08 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21059L3 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21059L4 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 3/8" | 9/32" | 2 | 0.13" | 1" | MS21059L5 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21059L6 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

A286 Stainless Steel—Lubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 1/8" | 1/16" | 2 | 0.098" | 13/32" | MS21076L04N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 11/32" | 3/32" | 0.172" | 5/64" | 2 | 0.098" | 7/16" | MS21076L06N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060L06 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076L08N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 61/64" | 13/32" | 1/32" | 0.203" | 7/32" | 2 | 0.098" | 11/16" | MS21060L08 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076L3N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060L3 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076L4N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060L4 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076L5N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 19/64" | 39/64" | 3/64" | 3/8" | 9/32" | 2 | 0.13" | 1" | MS21060L5 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 19/64" | 43/64" | 1/16" | 0.453" | 19/64" | 2 | 0.13" | 1" | MS21060L6 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silver-Plated A286 Stainless Steel—Unlubricated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 21/32" | 5/16" | 3/32" | 1/8" | 1/16" | 2 | 0.098" | 13/32" | MS21076-04N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 61/64" | 13/32" | 1/32" | 0.172" | 11/64" | 2 | 0.098" | 11/16" | MS21060-06 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 45/64" | 23/64" | 3/32" | 0.203" | 5/32" | 2 | 0.098" | 15/32" | MS21076-08N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 47/64" | 13/32" | 3/32" | 0.234" | 5/32" | 2 | 0.098" | 1/2" | MS21076-3N | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 61/64" | 13/32" | 1/32" | 0.234" | 7/32" | 2 | 0.098" | 11/16" | MS21060-3 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 51/64" | 1/2" | 3/32" | 0.313" | 3/16" | 2 | 0.098" | 9/16" | MS21076-4N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 19/64" | 33/64" | 1/32" | 0.313" | 1/4" | 2 | 0.098" | 1" | MS21060-4 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/64" | 37/64" | 7/64" | 0.391" | 7/32" | 2 | 0.13" | 23/32" | MS21076-5N | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Self-Tapping Adhesive Snap-In Standoffs

Base, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg., mm | Lg. | Wd. | Max. Temp., ° F | Mounting Fasteners Included | Adhesive Type | Flammability Rating | For Screw Size | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon 6/6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Center Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | 20 | 20 | 175 | No | Acrylic | UL 94 V-2 | M3 | 10 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corner Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 14 | 14 | 175 | Yes | Acrylic | UL 94 V-2 | M2.5 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 20 | 20 | 175 | Yes | Acrylic | UL 94 V-2 | M3 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 14 | 14 | 175 | Yes | Acrylic | UL 94 V-2 | M2.5 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 20 | 20 | 175 | Yes | Acrylic | UL 94 V-2 | M3 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 25 | 25 | 175 | Yes | Acrylic | UL 94 V-2 | M4 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 20 | 20 | 175 | Yes | Acrylic | UL 94 V-2 | M3 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20 | 20 | 175 | Yes | Acrylic | UL 94 V-2 | M3 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 25 | 25 | 175 | Yes | Acrylic | UL 94 V-2 | M4 | 4 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||