Filter by

Seal ID

Seal OD

Shaft Diameter

For Use With

For Shaft Motion

Cylinder Seal Type

Minimum Temperature

Maximum Temperature

For Cylinder Type

Groove Diameter

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Spring-Loaded Seals

|  | |

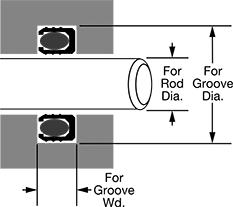

Side 1 | Side 2 | Profile |

|  |

Rod Installation | Piston Installation |

For Rod Sealing | For Piston Sealing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | For Groove Dia. | For Bore Dia. | For Groove Dia. | Max. Speed, ft/sec | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UHMW Polyethylene with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N27 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N29 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N28 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

UHMW Polyethylene with 316 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 180 | Durometer 67D | White | 5383N25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K63 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K64 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K65 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K66 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K67 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K68 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K69 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K81 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K82 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K83 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K84 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K85 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K86 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K87 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 450 | Not Rated | White | 13125K88 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Graphite-Filled PTFE with 302 Stainless Steel-Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.056" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.188" | 3/16" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K71 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.101" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 0.250" | 1/4" | 0.125" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K73 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.313" | 5/16" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K74 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.375" | 3/8" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K75 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.500" | 1/2" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K76 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.149" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 0.375" | 3/8" | 0.188" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K77 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.438" | 7/16" | 0.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K78 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.563" | 9/16" | 0.375" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K79 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.688" | 11/16" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K91 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.938" | 15/16" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K92 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.188" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.750" | 3/4" | 0.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K93 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1.000" | 1" | 0.750" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K94 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.250" | 1 1/4" | 1.000" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K95 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.500" | 1 1/2" | 1.250" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K96 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.750" | 1 3/4" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.250" | 2 1/4" | 2.000" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 0.268" Wide Grooves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.875" | 1 7/8" | 1.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K97 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.875" | 2 7/8" | 2.500" | 1.6 | 250 | -320 to 450 | Not Rated | Black | 13125K98 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

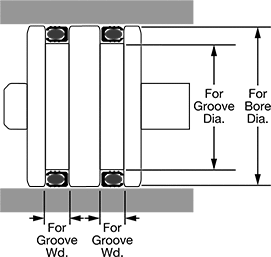

Cartridge Mechanical Shaft Seals

Seal | Fluoroelastomer Diaphragm | EPDM Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | ID | OD | Wd. | Max. Pressure, psi | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Case and C276 Nickel Spring with PTFE Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 2.626" | 2.736" | 220 | 4887N11 | 000000000 | 4887N35 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1.125" | 2.752" | 2.736" | 220 | 4887N12 | 00000000 | 4887N36 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1.25" | 2.874" | 2.736" | 220 | 4887N13 | 00000000 | 4887N37 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1.375" | 3.063" | 2.736" | 220 | 4887N14 | 00000000 | 4887N38 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1.5" | 3.437" | 2.815" | 220 | 4887N15 | 00000000 | 4887N39 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1.625" | 3.437" | 2.815" | 220 | 4887N16 | 00000000 | 4887N41 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1.75" | 3.563" | 2.815" | 220 | 4887N17 | 00000000 | 4887N42 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 1.875" | 3.874" | 2.815" | 220 | 4887N18 | 00000000 | 4887N43 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 3.874" | 2.815" | 220 | 4887N19 | 00000000 | 4887N44 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 mm | 24 mm | 66.7 mm | 69.5 mm | 220 | 4887N21 | 00000000 | 4887N45 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 25 mm | 66.7 mm | 69.5 mm | 220 | 4887N22 | 00000000 | 4887N46 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 mm | 28 mm | 69.9 mm | 69.5 mm | 220 | 4887N23 | 00000000 | 4887N47 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 30 mm | 73 mm | 69.5 mm | 220 | 4887N24 | 00000000 | 4887N48 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 mm | 32 mm | 73 mm | 69.5 mm | 220 | 4887N25 | 00000000 | 4887N49 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 mm | 33 mm | 77.8 mm | 69.5 mm | 220 | 4887N26 | 00000000 | 4887N51 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 35 mm | 77.8 mm | 69.5 mm | 220 | 4887N27 | 00000000 | 4887N52 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 38 mm | 87.3 mm | 71.5 mm | 220 | 4887N28 | 00000000 | 4887N53 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 40 mm | 87.3 mm | 71.5 mm | 220 | 4887N29 | 00000000 | 4887N54 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 mm | 43 mm | 90.5 mm | 71.5 mm | 220 | 4887N31 | 00000000 | 4887N55 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 mm | 45 mm | 90.5 mm | 71.5 mm | 220 | 4887N32 | 00000000 | 4887N56 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 mm | 48 mm | 98.4 mm | 71.5 mm | 220 | 4887N33 | 00000000 | 4887N57 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 50 mm | 98.4 mm | 71.5 mm | 220 | 4887N34 | 00000000 | 4887N58 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

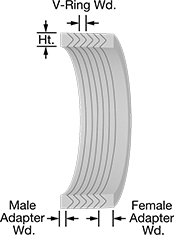

PTFE Stackable V-Ring Packing Seals

V-Rings | One Male and One Female Adapter | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | OD | Ht. | Temp. Range, ° F | pH Resistance | Hardness | Color | Food Industry Std. | V-Ring Wd. | Pkg. Qty. | Pkg. | Male Adapter Wd. | Female Adapter Wd. | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/8" | 0.188" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K31 | 000000 | 0.083" | 0.190" | 9572K61 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/16" | 0.188" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K32 | 00000 | 0.083" | 0.190" | 9572K62 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/4" | 0.188" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K33 | 00000 | 0.083" | 0.190" | 9572K63 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 7/8" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K37 | 00000 | 0.083" | 0.250" | 9572K67 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 7/8" | 0.188" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K35 | 00000 | 0.083" | 0.250" | 9572K65 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K39 | 00000 | 0.083" | 0.250" | 9572K69 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 1 1/16" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K41 | 00000 | 0.083" | 0.250" | 9572K71 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1 1/8" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K42 | 00000 | 0.083" | 0.250" | 9572K72 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K43 | 00000 | 0.083" | 0.250" | 9572K73 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 3/8" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K45 | 00000 | 0.083" | 0.250" | 9572K75 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/2" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K47 | 00000 | 0.083" | 0.250" | 9572K77 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1 5/8" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K48 | 00000 | 0.083" | 0.250" | 9572K78 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 3/4" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.083" | 5 | 9572K49 | 00000 | 0.083" | 0.250" | 9572K79 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 2" | 0.313" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.140" | 5 | 9572K51 | 00000 | 0.140" | 0.310" | 9572K81 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 1/8" | 0.313" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.140" | 5 | 9572K52 | 00000 | 0.140" | 0.310" | 9572K82 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 3/8" | 0.313" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.140" | 5 | 9572K54 | 00000 | 0.140" | 0.310" | 9572K84 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/2" | 0.250" | -110 to 500 | 1 to 9 | Rockwell R60 (Extra Hard) | White | FDA Compliant 21 CFR 177.1550 | 0.140" | 5 | 9572K55 | 00000 | 0.140" | 0.310" | 9572K85 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

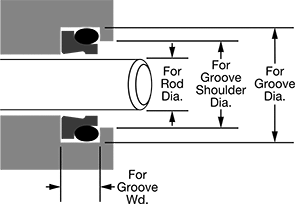

High-Speed Rod Wipers

|  |  | |

Side 1 | Side 2 | Profile |

For Groove | O-Ring | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia. | Dia. | Shoulder Dia. | Wd. | Max. Speed, ft/sec | Temp. Range, ° F | Hardness | Color | Hardness | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Molybdenum Disulfide-Filled PTFE with Buna-N O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.893" | 0.685" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.268" | 1.060" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1.564" | 1.435" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2.018" | 1.810" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.268" | 2.060" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 2.518" | 2.310" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2.768" | 2.560" | 0.201" | 13 | -30 to 230 | Durometer 60D (Extra Hard) | Gray | Durometer 70A (Hard) | Black | 1623N17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||