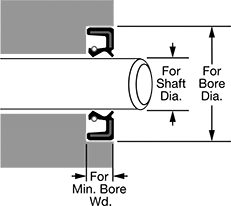

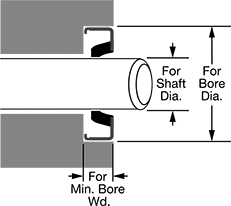

Bore-Sealing Spring-Loaded Rotary Shaft Seals with Wiper Lip

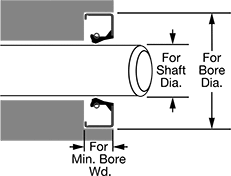

Ribbed Buna-N over steel creates a tight seal with the bore, even when mating with a rough surface or in a split housing. Also known as oil seals, these retain oil on rotating shafts in motors, pumps, bearings, and gearboxes. They have a secondary lip that blocks contaminants and a spring that secures the sealing-lip to prevent leaks. Press-fit seals into the bore around the shaft. Seals with a maximum pressure of 145 psi should be secured with a retaining ring.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

Spring-Loaded Rotary Shaft Seals with Wiper Lip

Used to retain oil on rotating shafts in motors, pumps, bearings, and gearboxes, these seals have a secondary lip that blocks contaminants. Also known as oil seals, a spring secures the lip against the shaft, preventing messy leaks. Press-fit seals into the bore around the shaft. Seals with a maximum pressure of 50 psi should be secured with a retaining ring.

Seals with an acrylic-coated case have a coating that compensates for surface imperfections in the housing bore for a tight seal on the OD.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Bore | Case | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Dia. | Min. Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Finish | Color | Specifications Met | Each | |

Buna-N Rubber with Steel Case and Spring | ||||||||||||

| 1 1/8" | 1.625" | 0.272" | 3,700 | 10 | -40° to 210° | Durometer 80A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 00000 |

| 1 1/8" | 1.875" | 0.266" | 3,700 | 10 | -40° to 210° | Durometer 80A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 00000 |

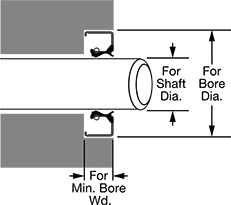

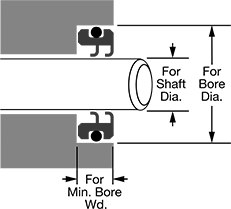

Spring-Loaded Rotary Shaft Seals

Also known as oil seals, use these to retain oil on rotating shafts in motors, pumps, bearings, and gearboxes. A spring secures the lip against the shaft, preventing messy leaks. Press-fit seals into the bore around the shaft.

Seals with an acrylic-coated case have a coating that compensates for surface imperfections in the housing bore for a tight seal on the OD.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Bore | Case | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Dia. | Min. Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Finish | Color | Specifications Met | Each | |

Buna-N Rubber with Steel Case and Spring | ||||||||||||

| 1 1/8" | 1.752" | 0.266" | 3,700 | 10 | -40° to 210° | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 0000000 | 000000 |

| 1 1/8" | 1.874" | 0.266" | 3,700 | 10 | -40° to 210° | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 00000000 | 00000 |

Rotary Shaft Seals for Grease

Also known as grease seals, these are designed to retain thick lubricant at low pressure in motors, pumps, bearings, and gearboxes. They have a light grip on the shaft that creates less friction than spring-loaded seals. Press-fit seals into the bore around the shaft.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Bore | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Dia. | Min. Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Specifications Met | Each | |

Buna-N Rubber with Steel Case | ||||||||||

| 1 1/8" | 1.375" | 0.141" | 3,700 | 10 | -40° to 210° | Durometer 75A (Hard) | Black | DIN 3760, ISO 6194 | 0000000 | 00000 |

High-Speed Rotary Shaft Seals

A slippery PTFE surface allows these seals to function at speeds at least 25% faster than other rotary shaft seals. Also known as oil seals, use these to retain oil on rotating shafts in motors, pumps, bearings, and gearboxes. An O-ring secures the lips to prevent leaks, while sealing against the housing. Press-fit seals into the bore around the shaft.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Bore | O-Ring | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Dia. | Min. Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Hardness | Color | Each | |

Graphite-Filled PTFE Plastic with Buna-N Rubber O-Ring | |||||||||||

| 1 1/8" | 1.625" | 0.323" | 17,000 | 150 | -40° to 250° | Durometer 60D (Extra Hard) | Black | Durometer 70A (Hard) | Black | 0000000 | 000000 |

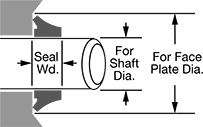

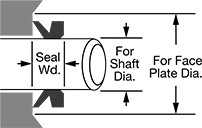

Shaft-Mounted Rotary Seals

Also known as V-rings and flingers, these seals protect shaft bearings by blocking dust and other contaminants while retaining lubricant. They’re Buna-N for excellent resistance to oil and grease. To install, stretch the seal over your shaft and press it firmly against the face plate. The Seal OD and Seal Width listed are the dimensions of the seal after it is installed.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Shaft | Seal | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dia. Range | For Face Plate Dia. | ID | OD | Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Each | |

Buna-N Rubber | ||||||||||||

| 1 1/8" | 1.070"-1.140" | 1.670"-1.740" | 0.984" | 1.725" | 0.375" | 6,200 | 100 | -20° to 225° | Durometer 85A (Hard) | Black | 0000000 | 00000 |

Heavy Duty Shaft-Mounted Rotary Seals

These seals are fluoroelastomer, so they have excellent chemical resistance and withstand temperatures up to 390° F. Also known as V-rings and flingers, they protect shaft bearings by blocking dust and other contaminants while retaining lubricant. To install, stretch the seal over your shaft and press it firmly against the face plate.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

For Shaft | Seal | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dia. Range | For Face Plate Dia. | ID | OD | Wd. | Max. Speed, rpm | Max. Pressure, psi | Temp. Range, °F | Hardness | Color | Each | |

Fluoroelastomer Rubber | ||||||||||||

| 1 1/8" | 1.063"-1.142" | 1.535"-1.614" | 0.984" | 1.299" | 0.295" | 6,100 | 5 | 5° to 390° | Durometer 60A (Medium) | Brown | 0000000 | 00000 |

Mechanical Pump Shaft Seals with Extended Spring

For use in waste water, boiler feed, and compressor pumps, these seals have an extra-long spring that accommodates variations in seal cavity length. They come furnished as two pieces—the seal and the seat. The seal is comprised of the case, spring, diaphragm, and washer, which come locked together as one piece. Seal Width represents the working height, which is the compressed length when installed. The seat is comprised of the seat and the gasket. Products cannot be sold outside North America due to restrictions.

Buna-N diaphragms and gaskets resist grease and a wide range of oils.

Viton® fluoroelastomer diaphragms and gaskets resist a wider range of chemicals than Buna-N.

EPDM diaphragms are more resistant to water and steam than Buna-N and Viton® fluoroelastomer, but aren’t as resistant to oils and chemicals.

Carbon washers are for use with clean liquids.

Silicon carbide washers have a hard surface that resists scratching, so they can be used with liquids that contain abrasives.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

Seal | Seat | Material | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Manufacturer Equivalent Number | Manufacturer/ Brand Equivalent | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Spring Shape | Includes | Max. Pressure, psi | Cannot Be Sold To | Each | |

304 Stainless Steel Case and Spring with Buna-N Rubber Diaphragm and Gasket | ||||||||||||||||

| 1 1/8" | 356 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.125" | 1.753" | 1.062" | 1.156" | 1.750" | 0.438" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

304 Stainless Steel Case and Spring with Viton® Fluoroelastomer Rubber Diaphragm and Gasket | ||||||||||||||||

| 1 1/8" | 356V | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.125" | 1.753" | 1.062" | 1.161" | 1.750" | 0.437" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 0000000 | 00000 |

| 1 1/8" | 356VSC | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.125" | 1.753" | 1.062" | 1.156" | 1.750" | 0.437" | Silicon Carbide | Silicon Carbide | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 000000 |

304 Stainless Steel Case and Spring with EPDM Rubber Diaphragm and Gasket | ||||||||||||||||

| 1 1/8" | 356E | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 1.125" | 1.753" | 1.062" | 1.161" | 1.750" | 0.439" | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 00000000 | 00000 |

Narrow-Profile Mechanical Pump Shaft Seals with Extended Spring

With a smaller seal OD than standards seals, these seals have an extended spring that accommodates variations in seal cavity length. They're used in waste water, boiler feed, and compressor pumps. Seals come furnished as two pieces—the seal and the seat. The seal is comprised of the case, spring, diaphragm, and washer, which come locked together as one piece. Seal Width represents the working height, which is the compressed length when installed. The seat is comprised of the seat and the gasket. Products cannot be sold outside North America due to restrictions.

Note: Maximum performance values cannot be achieved simultaneously; for example, speed is affected by pressure, temperature, and other operating conditions.

Seal | Seat | Material | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Manufacturer Equivalent Number | Manufacturer/ Brand Equivalent | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Max. Pressure, psi | Cannot Be Sold To | Each | |

316 Stainless Steel Case and Spring with Buna-N Rubber Diaphragm and Gasket | ||||||||||||||

| 1 1/8" | 204 | John Crane Type 1 Pac-Seal Type 51 Sealol Type 43 CE Long | 1.125" | 1.562" | 1.625" | 1.161" | 1.750" | 0.437" | Carbon | Ceramic | 150 | Outside North America | 00000000 | 000000 |

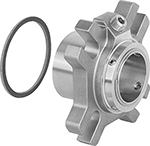

Cartridge Mechanical Seals

Install these seals faster and with less technical expertise than other mechanical shaft seals that come in two pieces. They come with their seal and seat already assembled. All have a carbon washer that is self-lubricating. However, this means their washer is too soft to be used with abrasive liquids and liquids with harsh additives.

Seals with a fluoroelastomer diaphragm can be used with a wider range of chemicals than EPDM diaphragms, including benzene, butyl alcohol, and fuels.

Seals with an EPDM diaphragm won’t break down from exposure to water and steam. However, they are for use with fewer chemicals.