Filter by

Seal ID

Seal OD

Shaft Diameter

Seal Width

For Use With

Bore Diameter

Maximum Rotation Speed

For Shaft Motion

Loaded Type

Maximum Pressure

Hardness Rating

Spring Material

Specifications Met

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

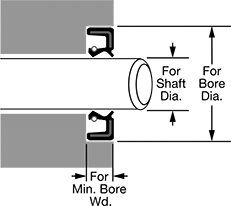

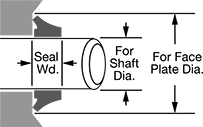

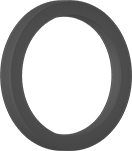

Bore-Sealing Spring-Loaded Rotary Shaft Seals with Wiper Lip

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Core and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 22.000 | 7.000 | 22.000 | 7.300 | 21,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 25.000 | 7.000 | 25.000 | 7.300 | 21,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N12 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 25.000 | 6.000 | 25.000 | 6.300 | 12,500 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T861 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 26.000 | 7.000 | 26.000 | 7.300 | 17,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N31 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 30.000 | 7.000 | 30.000 | 7.300 | 17,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N311 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 35.000 | 7.000 | 35.000 | 7.300 | 17,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N312 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 17.000 | 30.000 | 7.000 | 30.000 | 7.300 | 15,400 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N13 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 30.000 | 7.000 | 30.000 | 7.300 | 13,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N313 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 35.000 | 7.000 | 35.000 | 7.300 | 13,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N314 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 40.000 | 7.000 | 40.000 | 7.300 | 13,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N315 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 24.000 | 40.000 | 6.000 | 40.000 | 6.300 | 7,700 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T862 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 7.000 | 35.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N14 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 38.000 | 7.000 | 38.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N15 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N16 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 47.000 | 7.000 | 47.000 | 7.300 | 10,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N316 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 8.000 | 52.000 | 8.300 | 10,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N17 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 40.000 | 7.000 | 40.000 | 7.300 | 8,700 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N18 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 42.000 | 7.000 | 42.000 | 7.300 | 8,900 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N317 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 45.000 | 8.000 | 45.000 | 8.300 | 8,700 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N19 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 47.000 | 7.000 | 47.000 | 7.300 | 8,700 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N21 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 52.000 | 7.000 | 52.000 | 7.300 | 8,900 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N318 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 32.000 | 47.000 | 8.000 | 47.000 | 8.300 | 8,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N22 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 32.000 | 48.000 | 7.000 | 48.000 | 7.300 | 5,900 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T864 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 47.000 | 7.000 | 47.000 | 7.300 | 7,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N319 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 50.000 | 7.000 | 50.000 | 7.300 | 7,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N32 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 50.000 | 8.000 | 50.000 | 8.300 | 7,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N321 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 52.000 | 6.000 | 52.000 | 6.300 | 5,400 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T865 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 52.000 | 7.000 | 52.000 | 7.300 | 7,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N322 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 52.000 | 8.000 | 52.000 | 8.300 | 7,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N323 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 54.000 | 6.000 | 54.000 | 6.300 | 5,400 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T866 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 52.000 | 7.000 | 52.000 | 7.300 | 6,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N324 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 52.000 | 8.000 | 52.000 | 8.300 | 6,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N325 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 55.000 | 7.000 | 55.000 | 7.300 | 4,700 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T867 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 55.000 | 7.000 | 55.000 | 7.300 | 6,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N326 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 55.000 | 8.000 | 55.000 | 8.300 | 6,500 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N23 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 45.000 | 62.000 | 7.000 | 62.000 | 7.300 | 4,200 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T868 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 45.000 | 75.000 | 8.000 | 75.000 | 8.300 | 5,800 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N24 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47 | 47.000 | 62.000 | 7.000 | 62.000 | 7.300 | 4,000 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T869 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 65.000 | 8.000 | 65.000 | 8.300 | 5,300 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N327 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 68.000 | 8.000 | 68.000 | 8.300 | 5,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 72.000 | 7.000 | 72.000 | 7.300 | 3,700 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T871 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 72.000 | 8.000 | 72.000 | 8.300 | 5,200 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N26 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 55.000 | 83.000 | 7.000 | 83.000 | 7.300 | 3,400 | 145 | -40 to 212 | Durometer 70A (Hard) | Black | — | 5154T872 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 60.000 | 72.000 | 8.000 | 72.000 | 8.300 | 2,760 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N81 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | 65.000 | 80.000 | 8.000 | 80.000 | 8.300 | 2,640 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N82 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 70.000 | 85.000 | 8.000 | 85.000 | 8.300 | 2,520 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N83 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 75.000 | 95.000 | 10.000 | 95.000 | 10.300 | 2,400 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N84 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 80.000 | 105.000 | 10.000 | 105.000 | 10.300 | 2,340 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N85 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85 | 85.000 | 100.000 | 9.000 | 100.000 | 9.300 | 2,220 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N86 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 90.000 | 110.000 | 12.000 | 110.000 | 12.300 | 2,160 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N87 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 95 | 95.000 | 110.000 | 10.000 | 110.000 | 10.300 | 2,100 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N88 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 100.000 | 120.000 | 12.000 | 120.000 | 12.300 | 2,600 | 7 | -40 to 210 | Durometer 75A (Hard) | Gray | DIN 3760, ISO 6194 | 1199N27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

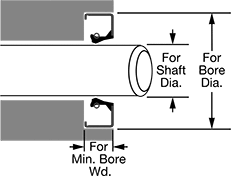

Shaft-Mounted Rotary Shaft Seals

|  |  | |

Side 1 | Side 2 | Profile |

For Shaft, mm | Seal, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Dia. Range | For Faceplate Dia., mm | ID | OD | Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 9.500 to 11.500 | 9.500 to 11.500 | 9.000 | 15.000 | 3.000 | 10,100 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K101 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 11.500 to 12.500 | 20.500 to 21.500 | 10.500 | 16.500 | 3.000 | 14,600 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K71 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 13.500 to 15.500 | 22.500 to 24.500 | 12.500 | 18.500 | 3.000 | 12,200 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K72 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 15.500 to 17.500 | 24.500 to 26.500 | 14.000 | 20.000 | 3.000 | 10,900 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K73 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 17.500 to 19.000 | 17.500 to 19.000 | 16.000 | 22.000 | 3.000 | 6,900 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K102 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 19.000 to 21.000 | 31.000 to 33.000 | 18.000 | 26.000 | 4.000 | 8,500 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K74 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 21.000 to 24.000 | 21.000 to 24.000 | 20.000 | 28.000 | 4.000 | 5,400 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K103 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 | 24.000 to 27.000 | 36.000 to 39.000 | 22.000 | 30.000 | 7.500 | 6,900 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K75 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 29.000 to 31.000 | 41.000 to 43.000 | 27.000 | 35.000 | 4.000 | 5,700 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K76 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 31.000 to 33.000 | 31.000 to 33.000 | 29.000 | 37.000 | 4.000 | 4,100 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K104 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 33.000 to 36.000 | 45.000 to 48.000 | 31.000 | 39.000 | 4.000 | 4,900 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K77 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41 | 38.000 to 43.000 | 53.000 to 58.000 | 36.000 | 46.000 | 5.000 | 4,200 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K78 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 43.000 to 48.000 | 43.000 to 48.000 | 40.000 | 50.000 | 5.000 | 3,000 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K105 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 51 | 48.000 to 53.000 | 63.000 to 68.000 | 45.000 | 55.000 | 5.000 | 3,400 | 4 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K79 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 53.000 to 58.000 | 53.000 to 58.000 | 49.000 | 59.000 | 5.000 | 2,500 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K106 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 58.000 to 63.000 | 58.000 to 63.000 | 54.000 | 64.000 | 5.000 | 2,300 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K107 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | 63.000 to 68.000 | 63.000 to 68.000 | 58.000 | 68.000 | 5.000 | 2,200 | 5 | -40 to 212 | Durometer 60A (Medium) | Black | 9562K108 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

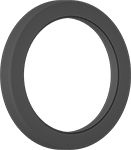

Rotary Shaft Seals for Grease

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 16.000 | 3.000 | 16.000 | 3.300 | 15,900 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T811 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 18.000 | 3.000 | 18.000 | 3.300 | 15,900 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T812 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 19.000 | 3.000 | 19.000 | 3.300 | 15,900 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T813 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 21.000 | 3.000 | 21.000 | 3.300 | 12,700 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T814 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 17.000 | 23.000 | 3.000 | 23.000 | 3.300 | 11,200 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T816 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 26.000 | 4.000 | 26.000 | 4.300 | 9,500 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T817 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 28.000 | 4.000 | 28.000 | 4.300 | 9,500 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T818 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 32.000 | 4.000 | 32.000 | 4.300 | 7,600 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T819 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 4.000 | 35.000 | 4.300 | 7,600 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T822 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 37.000 | 4.000 | 37.000 | 4.300 | 6,300 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T824 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 40.000 | 4.000 | 40.000 | 4.300 | 6,300 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T823 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 42.000 | 4.000 | 42.000 | 4.300 | 5,400 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T825 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 50.000 | 4.000 | 50.000 | 4.300 | 4,700 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T827 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 58.000 | 4.000 | 58.000 | 4.300 | 3,800 | Not Rated | -20 to 212 | Durometer 70A (Hard) | Black | 5154T831 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

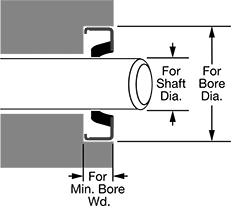

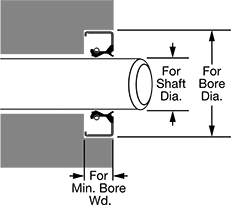

Spring-Loaded Rotary Shaft Seals

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | Case | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Finish | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 22.000 | 7.000 | 22.000 | 7.300 | 3,200 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T63 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 25.000 | 7.000 | 25.000 | 7.300 | 3,200 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T64 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 28.000 | 7.000 | 28.000 | 7.300 | 3,700 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T321 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15.000 | 32.000 | 7.000 | 32.000 | 7.300 | 3,700 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T322 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 17.000 | 30.000 | 7.000 | 30.000 | 7.300 | 3,900 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T65 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 30.000 | 7.000 | 30.000 | 7.300 | 3,900 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T323 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 35.000 | 7.000 | 35.000 | 7.300 | 3,900 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T324 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 40.000 | 7.000 | 40.000 | 7.300 | 3,900 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T325 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 35.000 | 7.000 | 35.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T66 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 38.000 | 7.000 | 38.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T67 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T68 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 8.000 | 52.000 | 8.300 | 3,800 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T69 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 40.000 | 7.000 | 40.000 | 7.300 | 3,600 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T71 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 45.000 | 8.000 | 45.000 | 8.300 | 3,600 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T72 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 47.000 | 7.000 | 47.000 | 7.300 | 3,600 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T73 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 32.000 | 47.000 | 8.000 | 47.000 | 8.300 | 3,600 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T74 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 47.000 | 7.000 | 47.000 | 7.300 | 3,400 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T326 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 50.000 | 8.000 | 50.000 | 8.300 | 3,400 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T327 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 52.000 | 8.000 | 52.000 | 8.300 | 3,400 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T328 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 55.000 | 8.000 | 55.000 | 8.300 | 3,300 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T75 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 45.000 | 75.000 | 8.000 | 75.000 | 8.300 | 3,100 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T76 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 68.000 | 8.000 | 68.000 | 8.300 | 3,000 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T77 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 72.000 | 8.000 | 72.000 | 8.300 | 3,000 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T78 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 100.000 | 120.000 | 12.000 | 120.000 | 12.300 | 2,000 | 10 | -40 to 210 | Durometer 75A (Hard) | Black | Acrylic Coated | Green | DIN 3760, ISO 6194 | 5154T79 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring-Loaded Rotary Shaft Seals with Wiper Lip

|  |  | |

Side 1 | Side 2 | Profile |

Seal, mm | For Bore, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Dia. | Min.Wd. | Max. Rotation Speed, rpm | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Buna-N with Steel Case and Steel Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 12.000 | 20.000 | 5.000 | 20.000 | 5.300 | 15,900 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T111 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 30.000 | 7.000 | 30.000 | 7.300 | 9,500 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T114 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 20.000 | 35.000 | 7.000 | 35.000 | 7.300 | 9,500 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T115 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 40.000 | 7.000 | 40.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T116 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 47.000 | 7.000 | 47.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T117 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25.000 | 52.000 | 7.000 | 52.000 | 7.300 | 7,600 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T118 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30.000 | 42.000 | 7.000 | 42.000 | 7.300 | 6,300 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T119 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 47.000 | 7.000 | 47.000 | 7.300 | 5,400 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T121 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35.000 | 52.000 | 7.000 | 52.000 | 7.300 | 5,400 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T122 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40.000 | 52.000 | 7.000 | 52.000 | 7.300 | 4,700 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T123 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50.000 | 65.000 | 8.000 | 65.000 | 8.300 | 3,800 | 7 | -20 to 212 | Durometer 70A (Hard) | Black | DIN 3761, ISO 6194 | 5154T125 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rod-Sealing Wipers

ISO 6195 Type C Rod Wipers

|  |  |  |

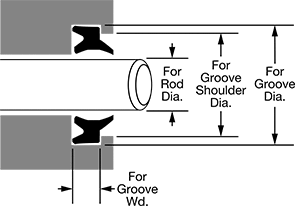

Side 1 | Side 2 | Profile |

For Groove, mm | Seal, mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rod Dia., mm | Dia. | Shoulder Dia. | Wd. | Wd. | Overall Wd. | Max. Speed, ft/sec | Max. Pressure, psi | Temp. Range, ° F | Hardness | Color | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyurethane Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 22.000 | 18.500 | 4.000 | 4.000 | 6.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N41 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | 24.000 | 20.500 | 4.000 | 4.000 | 6.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N42 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 31.000 | 27.500 | 4.000 | 4.000 | 6.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 36.000 | 31.000 | 5.000 | 5.000 | 7.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N44 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 43.000 | 38.000 | 5.000 | 5.000 | 7.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N45 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 48.000 | 43.000 | 5.000 | 5.000 | 7.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N46 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 53.000 | 48.000 | 5.000 | 5.000 | 7.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N47 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 58.000 | 53.000 | 5.000 | 5.000 | 7.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N48 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 70.000 | 63.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N51 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | 75.000 | 68.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N52 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 80.000 | 73.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 | 90.000 | 83.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N54 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90 | 100.000 | 93.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N55 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 110.000 | 103.000 | 6.000 | 6.000 | 8.000 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N56 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 120 | 135.000 | 124.000 | 8.500 | 8.500 | 10.500 | 3 | 290 | -30 to 212 | Durometer 95A (Extra Hard) | Blue | 1737N57 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mechanical Pump Shaft Seals with Extended Spring

|

Seal with Retainer and Straight Spring |

Seal, mm | Seat, mm | Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | Mfr./Brand Equiv. | ID | OD | Wd. | ID | OD | Wd. | Washer | Seat | Spring Shape | Includes | Max. Pressure, psi | Cannot Be Sold To | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Case and 304 Stainless Steel Spring with Buna-N Diaphragm and Buna-N Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 12.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K555 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 13.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K565 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 14.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K568 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 15.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K571 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 16.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K574 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 17.000 | 27.000 | 22.250 | 19.700 | 35.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K575 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 18.000 | 30.700 | 22.250 | 19.700 | 35.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K577 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 20.000 | 33.400 | 23.750 | 23.900 | 38.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K59 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 22.000 | 33.400 | 23.750 | 23.900 | 38.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K605 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 24.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K606 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 25.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K609 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 28.000 | 45.600 | 27.000 | 30.680 | 44.500 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K611 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 30.000 | 47.400 | 27.000 | 34.100 | 47.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K615 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 32.000 | 47.400 | 27.000 | 34.100 | 47.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K634 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 33.000 | 52.000 | 28.500 | 37.100 | 50.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K684 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 35.000 | 52.000 | 28.500 | 37.100 | 50.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K689 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 45.000 | 65.100 | 38.000 | 47.100 | 63.500 | 12.750 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K703 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 50.000 | 71.000 | 38.000 | 51.900 | 69.750 | 12.750 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K717 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Case and 304 Stainless Steel Spring with Viton® Fluoroelastomer Diaphragm and Viton® Fluoroelastomer Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 12.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K349 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 13.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K368 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 15.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K381 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 16.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K382 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 17.000 | 27.000 | 22.250 | 19.700 | 35.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K395 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 20.000 | 33.400 | 23.750 | 23.900 | 38.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K414 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 22.000 | 33.400 | 23.750 | 23.900 | 38.000 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K415 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 24.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K416 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 28.000 | 45.600 | 27.000 | 30.680 | 44.500 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K432 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 30.000 | 47.400 | 27.000 | 34.100 | 47.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K454 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 32.000 | 47.400 | 27.000 | 34.100 | 47.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K46 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 35.000 | 52.000 | 28.500 | 37.100 | 50.750 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K49 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 40.000 | 59.200 | 35.000 | 43.360 | 60.250 | 12.750 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K503 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Case and 304 Stainless Steel Spring with EPDM Diaphragm and EPDM Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 12.000 | 23.500 | 20.500 | 14.700 | 25.500 | 8.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K719 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 16.000 | 27.000 | 22.250 | 17.100 | 31.750 | 10.250 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K788 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | John Crane Type 21 Pac-Seal Type 21 Pac-Seal Type 31 Sealol Type 43 CE Short Sealol Type 43 CU Short | 25.000 | 39.200 | 25.500 | 26.500 | 41.250 | 11.000 | Carbon | Ceramic | Straight | Spring Retainer | 250 | Outside North America | 9281K838 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cartridge Mechanical Shaft Seals

Seal, mm | Fluoroelastomer Diaphragm | EPDM Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | ID | OD | Wd. | Max. Pressure, psi | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Case and C276 Nickel Spring with PTFE Gasket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 24 | 66.7 | 69.5 | 220 | 4887N21 | 000000000 | 4887N45 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 25 | 66.7 | 69.5 | 220 | 4887N22 | 00000000 | 4887N46 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 28 | 69.9 | 69.5 | 220 | 4887N23 | 00000000 | 4887N47 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 30 | 73 | 69.5 | 220 | 4887N24 | 00000000 | 4887N48 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32 | 32 | 73 | 69.5 | 220 | 4887N25 | 00000000 | 4887N49 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 33 | 33 | 77.8 | 69.5 | 220 | 4887N26 | 00000000 | 4887N51 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 35 | 77.8 | 69.5 | 220 | 4887N27 | 00000000 | 4887N52 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 | 38 | 87.3 | 71.5 | 220 | 4887N28 | 00000000 | 4887N53 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 40 | 87.3 | 71.5 | 220 | 4887N29 | 00000000 | 4887N54 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43 | 43 | 90.5 | 71.5 | 220 | 4887N31 | 00000000 | 4887N55 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45 | 45 | 90.5 | 71.5 | 220 | 4887N32 | 00000000 | 4887N56 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 | 48 | 98.4 | 71.5 | 220 | 4887N33 | 00000000 | 4887N57 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 50 | 98.4 | 71.5 | 220 | 4887N34 | 00000000 | 4887N58 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Joint Rod End Seals

|

Shown Installed |

For Rod End ID, mm | ID, mm | OD, mm | Overall Ht., mm | Material | Washer Material | Pair | ||

|---|---|---|---|---|---|---|---|---|

| 6 | 6 | 13 | 3 | Buna-N | 304 Stainless Steel | 4737T12 | 00000 | |

| 8 | 8 | 18 | 5 | Buna-N | 304 Stainless Steel | 4737T13 | 0000 | |

| 10 | 10 | 20 | 6 | Buna-N | 304 Stainless Steel | 4737T14 | 0000 | |

| 12 | 12 | 29 | 6 | Buna-N | 304 Stainless Steel | 4737T15 | 0000 | |

| 14 | 14 | 29 | 6 | Buna-N | 304 Stainless Steel | 4737T16 | 0000 | |

| 16 | 16 | 32 | 7 | Buna-N | 304 Stainless Steel | 4737T17 | 0000 | |

| 18 | 18 | 33 | 8 | Buna-N | 304 Stainless Steel | 4737T18 | 00000 | |

| 20 | 20 | 38 | 10 | Buna-N | 304 Stainless Steel | 4737T19 | 00000 |