Filter by

Shaft Diameter

Center Height

Material

Overall Width

Mounting Hole Center-to-Center

Overall Length

Length

Overall Height

Mounting Hole Diameter

Number of Mounting Holes

Support Mounting Location

Width

Height

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

REACH

Finish

Color

Performance

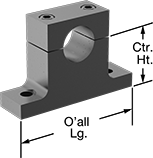

Easy-Access Base-Mount Linear Shaft Supports

Tee

Overall | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Lg. | Wd. | Ht. | Ctr. Ht. | Ctr. Ht. Tolerance | No. of | Ctr.-to-Ctr. | Dia. | Clamping Screw Thread Size | Fabrication | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Anodized 6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/2" | 1/2" | 1" | 11/16" | -0.002" to 0" | 2 | 1 1/8" | 0.16" | 6-32 | Machined | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 5/8" | 9/16" | 1 1/8" | 3/4" | -0.002" to 0" | 2 | 1 1/4" | 0.16" | 6-32 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 5/8" | 1 1/2" | 1" | -0.002" to 0" | 2 | 1 1/2" | 0.19" | 8-32 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2 1/2" | 11/16" | 1 1/2" | 1" | -0.002" to 0" | 2 | 1 7/8" | 0.22" | 10-24 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2 3/4" | 3/4" | 1 13/16" | 1 1/4" | -0.002" to 0" | 2 | 2" | 0.22" | 10-24 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 1/4" | 1" | 2 3/16" | 1 1/2" | -0.002" to 0" | 2 | 2 1/2" | 0.28" | 1/4"-20 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 4" | 1 1/8" | 2 5/8" | 1 3/4" | -0.002" to 0" | 2 | 3" | 0.34" | 5/16"-18 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 4 3/4" | 1 1/4" | 3" | 2" | -0.002" to 0" | 2 | 3 1/2" | 0.34" | 5/16"-18 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 6" | 1 1/2" | 3 3/4" | 2 1/2" | -0.002" to 0" | 2 | 4 1/2" | 0.41" | 3/8"-16 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 32 mm | 10 mm | 23 mm | 15 mm | -0.05 mm to 0 mm | 2 | 25 mm | 4.5 mm | M2.5 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 40 mm | 12 mm | 30 mm | 20 mm | -0.05 mm to 0 mm | 2 | 32 mm | 5.5 mm | M3 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 50 mm | 16 mm | 38 mm | 25 mm | -0.05 mm to 0 mm | 2 | 40 mm | 5.5 mm | M4 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 60 mm | 20 mm | 45 mm | 30 mm | -0.05 mm to 0 mm | 2 | 45 mm | 5.5 mm | M5 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 74 mm | 25 mm | 55 mm | 35 mm | -0.05 mm to 0 mm | 2 | 60 mm | 6.6 mm | M6 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 84 mm | 28 mm | 63 mm | 40 mm | -0.05 mm to 0 mm | 2 | 68 mm | 9 mm | M8 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 108 mm | 32 mm | 80 mm | 50 mm | -0.05 mm to 0 mm | 2 | 86 mm | 11 mm | M10 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

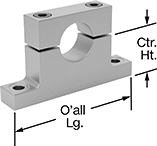

Low-Profile Tee

Overall | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Lg. | Wd. | Ht. | Ctr. Ht. | Ctr. Ht. Tolerance | No. of | Ctr.-to-Ctr. | Dia. | Clamping Screw Thread Size | Fabrication | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 5/8" | 3/8" | 7/8" | 9/16" | -0.002" to 0" | 2 | 1 1/4" | 0.16" | 6-32 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 3/4" | 3/8" | 1" | 5/8" | -0.002" to 0" | 2 | 1 3/8" | 0.16" | 6-32 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2" | 1 3/16" | 3/4" | -0.002" to 0" | 2 | 1 5/8" | 0.19" | 8-32 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2 5/8" | 1/2" | 1 7/16" | 15/16" | -0.002" to 0" | 2 | 2 1/8" | 0.22" | 10-24 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2 3/4" | 1/2" | 1 9/16" | 1" | -0.002" to 0" | 2 | 2 1/4" | 0.22" | 10-24 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 3/16" | 3/4" | 1 15/16" | 1 1/4" | -0.002" to 0" | 2 | 2 5/8" | 0.28" | 1/4"-20 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 3 3/4" | 3/4" | 2 5/16" | 1 1/2" | -0.002" to 0" | 2 | 3 1/8" | 0.34" | 5/16"-18 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 4" | 3/4" | 2 11/16" | 1 3/4" | -0.002" to 0" | 2 | 3 3/8" | 0.34" | 5/16"-18 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5" | 1 1/4" | 3 5/16" | 2 1/8" | -0.002" to 0" | 2 | 4 1/4" | 0.41" | 3/8"-16 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 44 mm | 10 mm | 21 mm | 12 mm | -0.05 mm to 0 mm | 2 | 35 mm | 4.5 mm | M4 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 46 mm | 12 mm | 25 mm | 14 mm | -0.05 mm to 0 mm | 2 | 38 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 48 mm | 12 mm | 25 mm | 14 mm | -0.05 mm to 0 mm | 2 | 40 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 62 mm | 13 mm | 31 mm | 18 mm | -0.05 mm to 0 mm | 2 | 50 mm | 5.5 mm | M5 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 65 mm | 13 mm | 36 mm | 22 mm | -0.05 mm to 0 mm | 2 | 54 mm | 5.5 mm | M5 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 80 mm | 19 mm | 44 mm | 27 mm | -0.05 mm to 0 mm | 2 | 66 mm | 6.6 mm | M6 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 96 mm | 19 mm | 52 mm | 32 mm | -0.05 mm to 0 mm | 2 | 78 mm | 9 mm | M8 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 108 mm | 19 mm | 66 mm | 40 mm | -0.05 mm to 0 mm | 2 | 90 mm | 9 mm | M8 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized 6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 1 1/16" | 5/16" | 1/2" | 5/16" | -0.002" to 0" | 2 | 13/16" | 0.14" | 4-40 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 3/16" | 5/16" | 9/16" | 5/16" | -0.002" to 0" | 2 | 15/16" | 0.14" | 4-40 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 5/8" | 3/8" | 7/8" | 9/16" | -0.002" to 0" | 2 | 1 1/4" | 0.16" | 6-32 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 3/4" | 3/8" | 1" | 5/8" | -0.002" to 0" | 2 | 1 3/8" | 0.16" | 6-32 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/2" | 1 3/16" | 3/4" | -0.002" to 0" | 2 | 1 5/8" | 0.19" | 8-32 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2 5/8" | 1/2" | 1 7/16" | 15/16" | -0.002" to 0" | 2 | 2 1/8" | 0.22" | 10-24 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2 3/4" | 1/2" | 1 9/16" | 1" | -0.002" to 0" | 2 | 2 1/4" | 0.22" | 10-24 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 3/16" | 3/4" | 1 15/16" | 1 1/4" | -0.002" to 0" | 2 | 2 5/8" | 0.28" | 1/4"-20 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 3 3/4" | 3/4" | 2 5/16" | 1 1/2" | -0.002" to 0" | 2 | 3 1/8" | 0.34" | 5/16"-18 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 4" | 3/4" | 2 11/16" | 1 3/4" | -0.002" to 0" | 2 | 3 3/8" | 0.34" | 5/16"-18 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5" | 1 1/4" | 3 5/16" | 2 1/8" | -0.002" to 0" | 2 | 4 1/4" | 0.41" | 3/8"-16 | Machined | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 mm | 21 mm | 6 mm | 10 mm | 6 mm | -0.05 mm to 0 mm | 2 | 17 mm | 2.4 mm | M2 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 mm | 24 mm | 6 mm | 13 mm | 7 mm | -0.05 mm to 0 mm | 2 | 20 mm | 2.4 mm | M2 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 36 mm | 8 mm | 18 mm | 10 mm | -0.05 mm to 0 mm | 2 | 30 mm | 3.4 mm | M3 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 42 mm | 10 mm | 20 mm | 11 mm | -0.05 mm to 0 mm | 2 | 34 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 44 mm | 10 mm | 21 mm | 12 mm | -0.05 mm to 0 mm | 2 | 35 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 46 mm | 12 mm | 25 mm | 14 mm | -0.05 mm to 0 mm | 2 | 38 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 48 mm | 12 mm | 25 mm | 14 mm | -0.05 mm to 0 mm | 2 | 40 mm | 4.5 mm | M4 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 62 mm | 13 mm | 31 mm | 18 mm | -0.05 mm to 0 mm | 2 | 50 mm | 5.5 mm | M5 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 65 mm | 14 mm | 36 mm | 22 mm | -0.05 mm to 0 mm | 2 | 54 mm | 5.5 mm | M5 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 80 mm | 19 mm | 44 mm | 27 mm | -0.05 mm to 0 mm | 2 | 66 mm | 6.6 mm | M6 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 96 mm | 19 mm | 52 mm | 32 mm | -0.05 mm to 0 mm | 2 | 78 mm | 9 mm | M8 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 100 mm | 19 mm | 60 mm | 34 mm | -0.05 mm to 0 mm | 2 | 84 mm | 9 mm | M8 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 108 mm | 19 mm | 66 mm | 40 mm | -0.05 mm to 0 mm | 2 | 90 mm | 9 mm | M8 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 mm | 120 mm | 25 mm | 75 mm | 45 mm | -0.05 mm to 0 mm | 2 | 100 mm | 9 mm | M8 | Machined | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

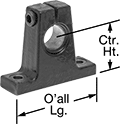

Base-Mount Linear Shaft Supports

Tee

Overall | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | Lg. | Wd. | Ht. | Ctr. Ht. | Ctr. Ht. Tolerance | No. of | Ctr.-to-Ctr. | Dia. | Clamping Screw Thread Size | Fabrication | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/2" | 1/2" | 1 1/16" | 11/16" | -0.002" to 0.002" | 2 | 1 1/8" | 0.16" | 6-32 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 5/8" | 5/8" | 1 3/16" | 3/4" | -0.002" to 0.002" | 2 | 1 1/4" | 0.16" | 6-32 | Machined | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 5/8" | 1 5/8" | 1" | -0.002" to 0.002" | 2 | 1 1/2" | 0.19" | 8-32 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 2 1/2" | 11/16" | 1 3/4" | 1" | -0.002" to 0.002" | 2 | 1 7/8" | 0.22" | 10-32 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2 3/4" | 3/4" | 2 1/8" | 1 1/4" | -0.002" to 0.002" | 2 | 2" | 0.22" | 10-32 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 1/4" | 1" | 2 9/16" | 1 1/2" | -0.002" to 0.002" | 2 | 2 1/2" | 0.28" | 1/4"-20 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 4" | 1 1/8" | 3" | 1 3/4" | -0.002" to 0.002" | 2 | 3" | 0.34" | 5/16"-18 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 4 3/4" | 1 1/4" | 3 1/2" | 2" | -0.002" to 0.002" | 2 | 3 1/2" | 0.34" | 5/16"-18 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 6" | 1 1/2" | 4 1/2" | 2 1/2" | -0.002" to 0.002" | 2 | 4 1/2" | 0.41" | 3/8"-16 | Cast | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1060 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 42 mm | 14 mm | 33 mm | 20 mm | -0.02 mm to 0.02 mm | 2 | 32 mm | 6 mm | M4 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 42 mm | 14 mm | 33 mm | 20 mm | -0.02 mm to 0.02 mm | 2 | 32 mm | 6 mm | M4 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 42 mm | 14 mm | 38 mm | 23 mm | -0.02 mm to 0.02 mm | 2 | 32 mm | 6 mm | M4 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 48 mm | 16 mm | 44 mm | 27 mm | -0.02 mm to 0.02 mm | 2 | 38 mm | 6 mm | M4 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 60 mm | 20 mm | 51 mm | 31 mm | -0.02 mm to 0.02 mm | 2 | 45 mm | 7 mm | M5 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 70 mm | 24 mm | 60 mm | 35 mm | -0.02 mm to 0.02 mm | 2 | 56 mm | 7 mm | M6 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 84 mm | 28 mm | 70 mm | 42 mm | -0.02 mm to 0.02 mm | 2 | 64 mm | 9 mm | M6 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 98 mm | 32 mm | 82 mm | 50 mm | -0.02 mm to 0.02 mm | 2 | 74 mm | 11 mm | M8 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 114 mm | 36 mm | 96 mm | 60 mm | -0.02 mm to 0.02 mm | 2 | 90 mm | 11 mm | M8 | Cast | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

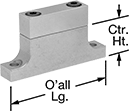

Machinable Easy-Access Base-Mount Linear Shaft Supports

Tee

Overall | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Shaft Dia. | Lg. | Wd. | Ht. | Ctr. Ht. | Ctr. Ht. Tolerance | No. of | Ctr.-to-Ctr. | Dia. | Clamping Screw Thread Size | Fabrication | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Anodized 6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 1/4" | 1" | 2 3/16" | 1 1/2" | -0.002" to 0" | 2 | 2 1/2" | 0.28" | 1/4"-20 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Tee

Overall | Mounting Hole | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Shaft Dia. | Lg. | Wd. | Ht. | Ctr. Ht. | Ctr. Ht. Tolerance | No. of | Ctr.-to-Ctr. | Dia. | Clamping Screw Thread Size | Fabrication | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized 6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3 3/16" | 3/4" | 1 15/16" | 1 1/4" | -0.002" to 0" | 2 | 2 5/8" | 0.28" | 1/4"-20 | Machined | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||